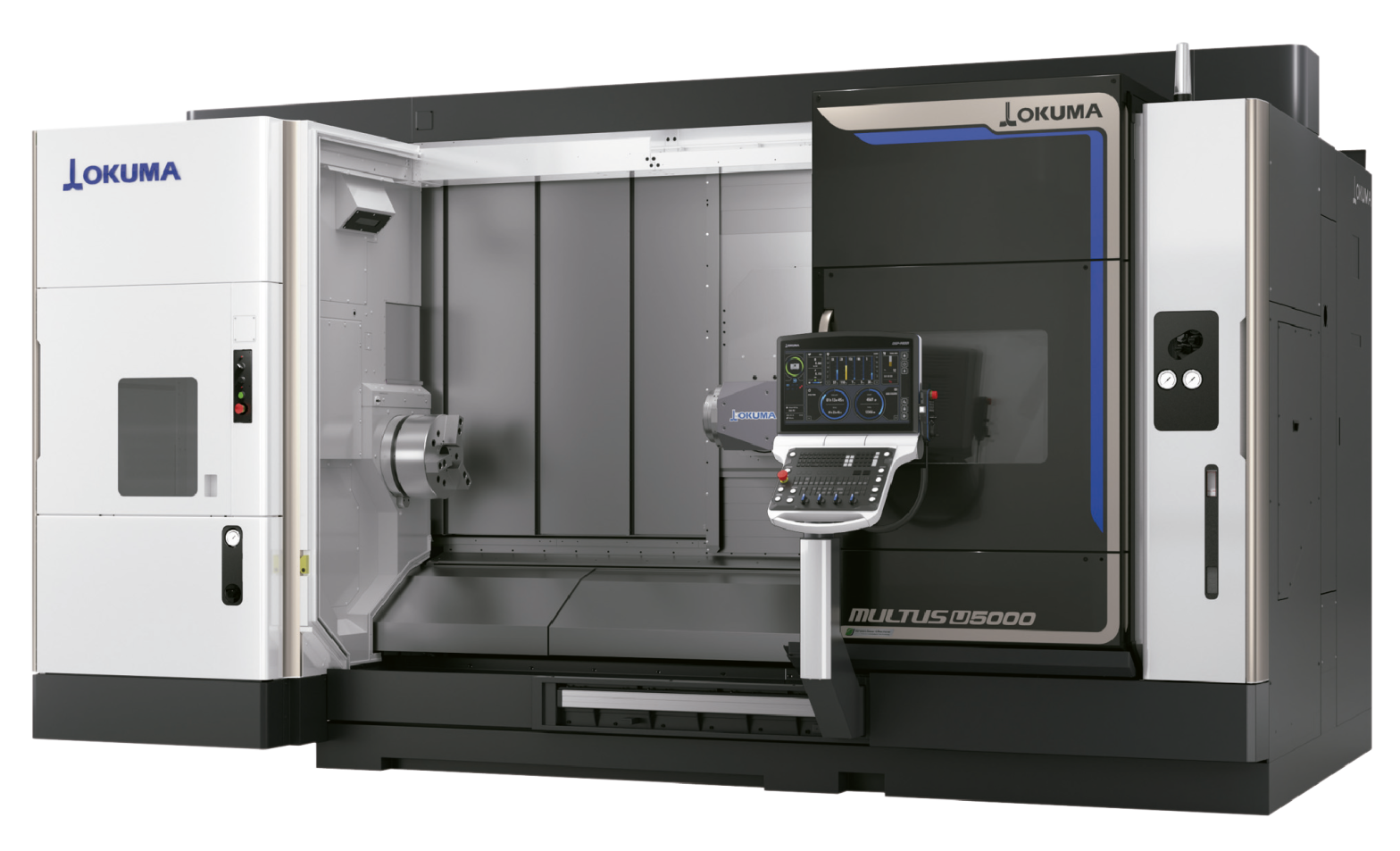

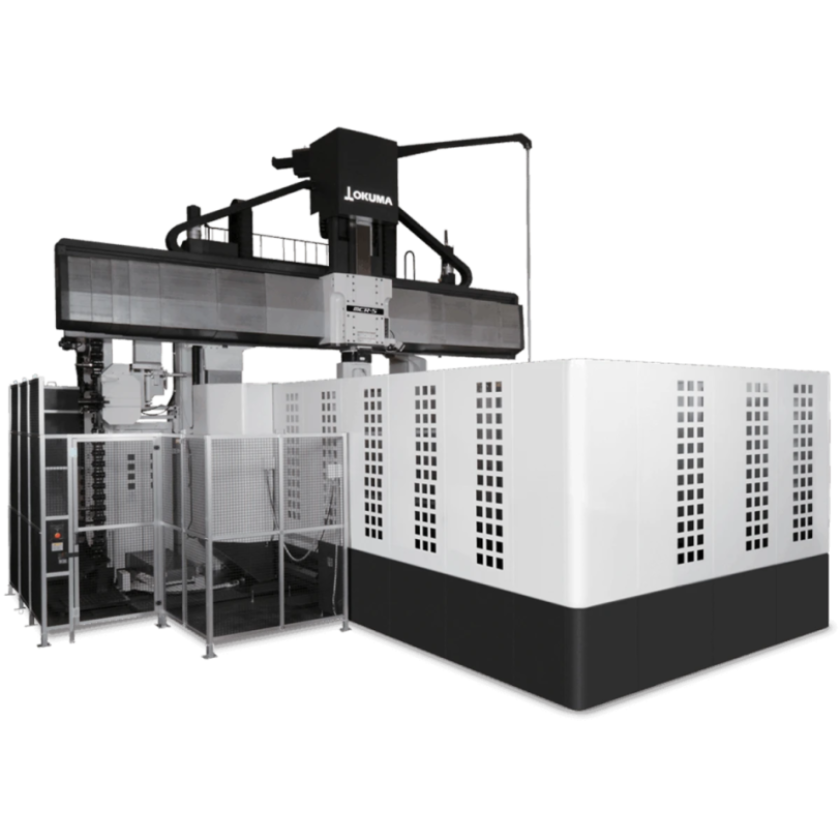

OKUMA

OKUMA

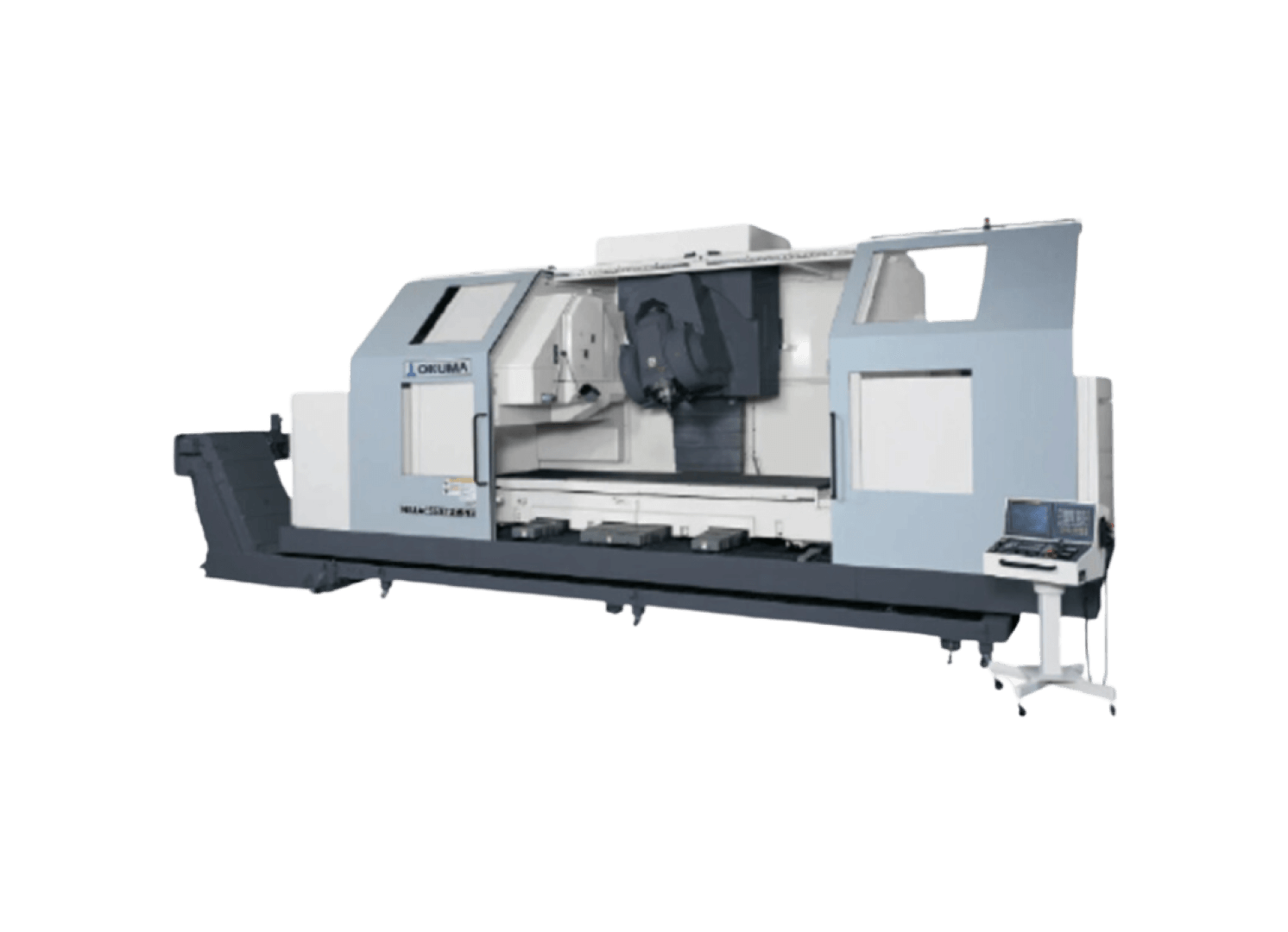

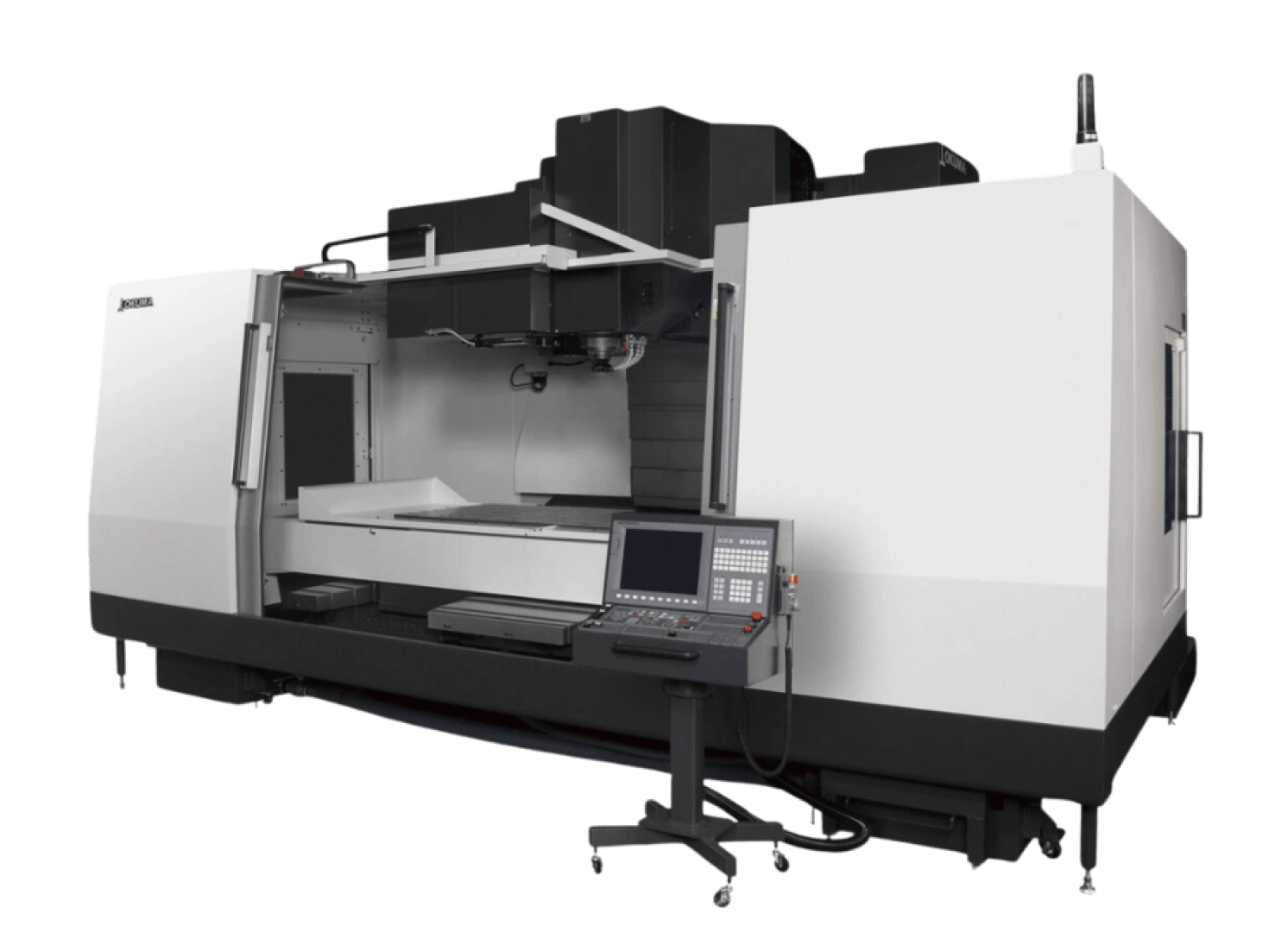

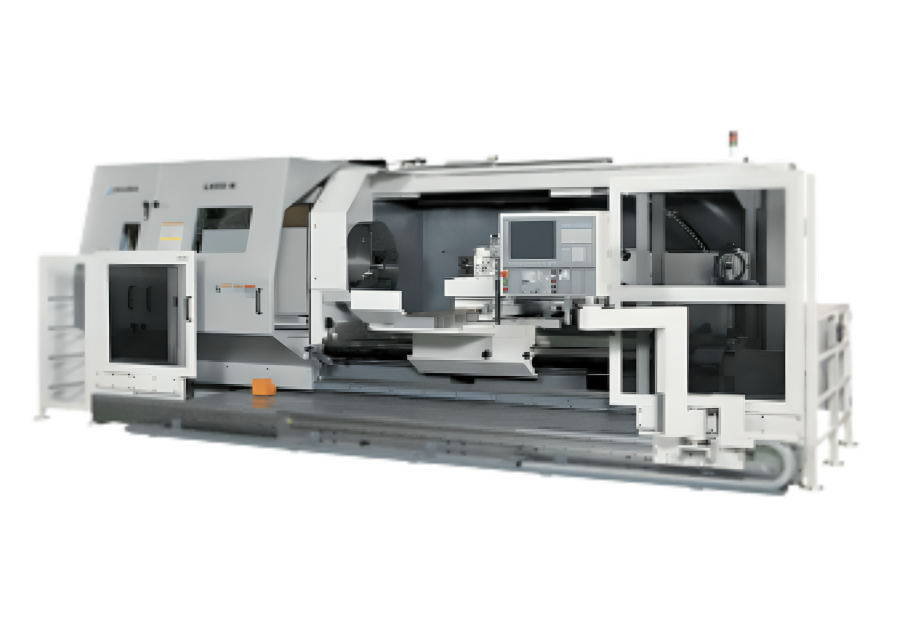

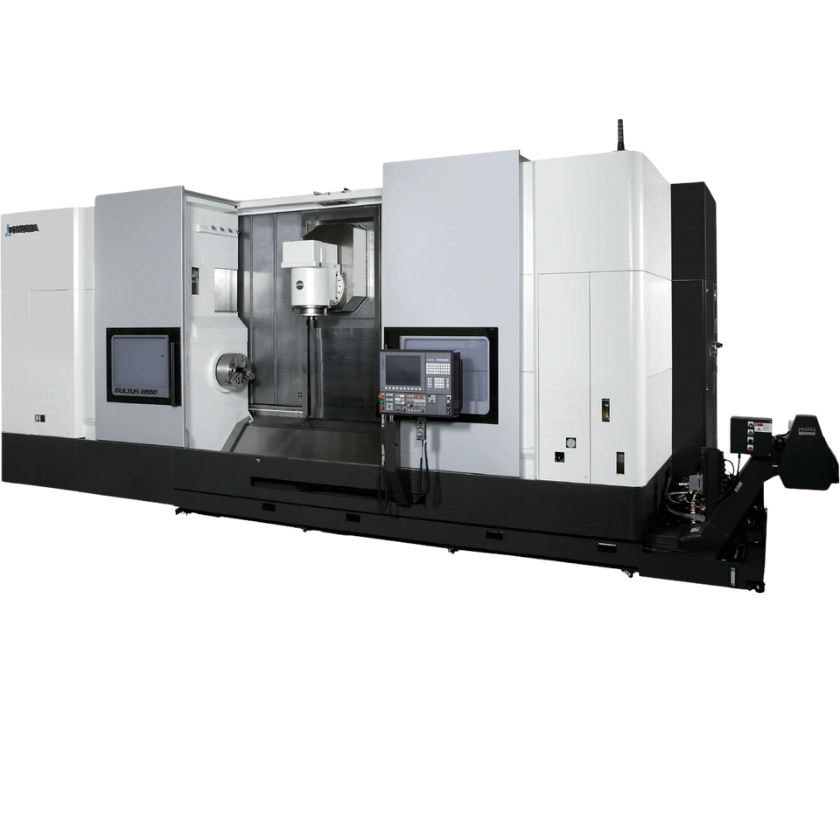

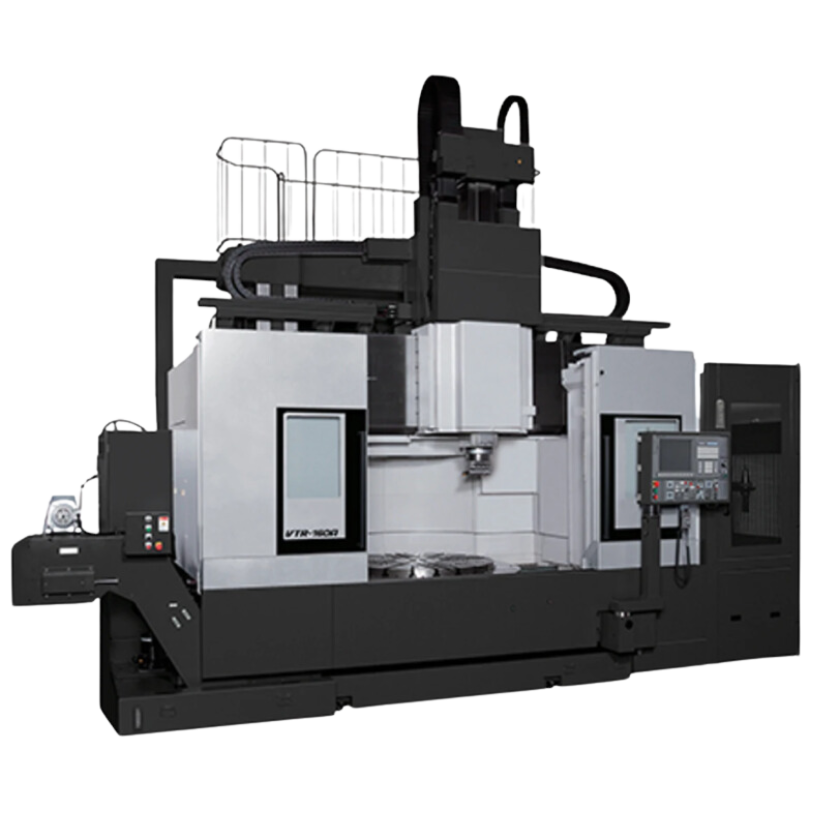

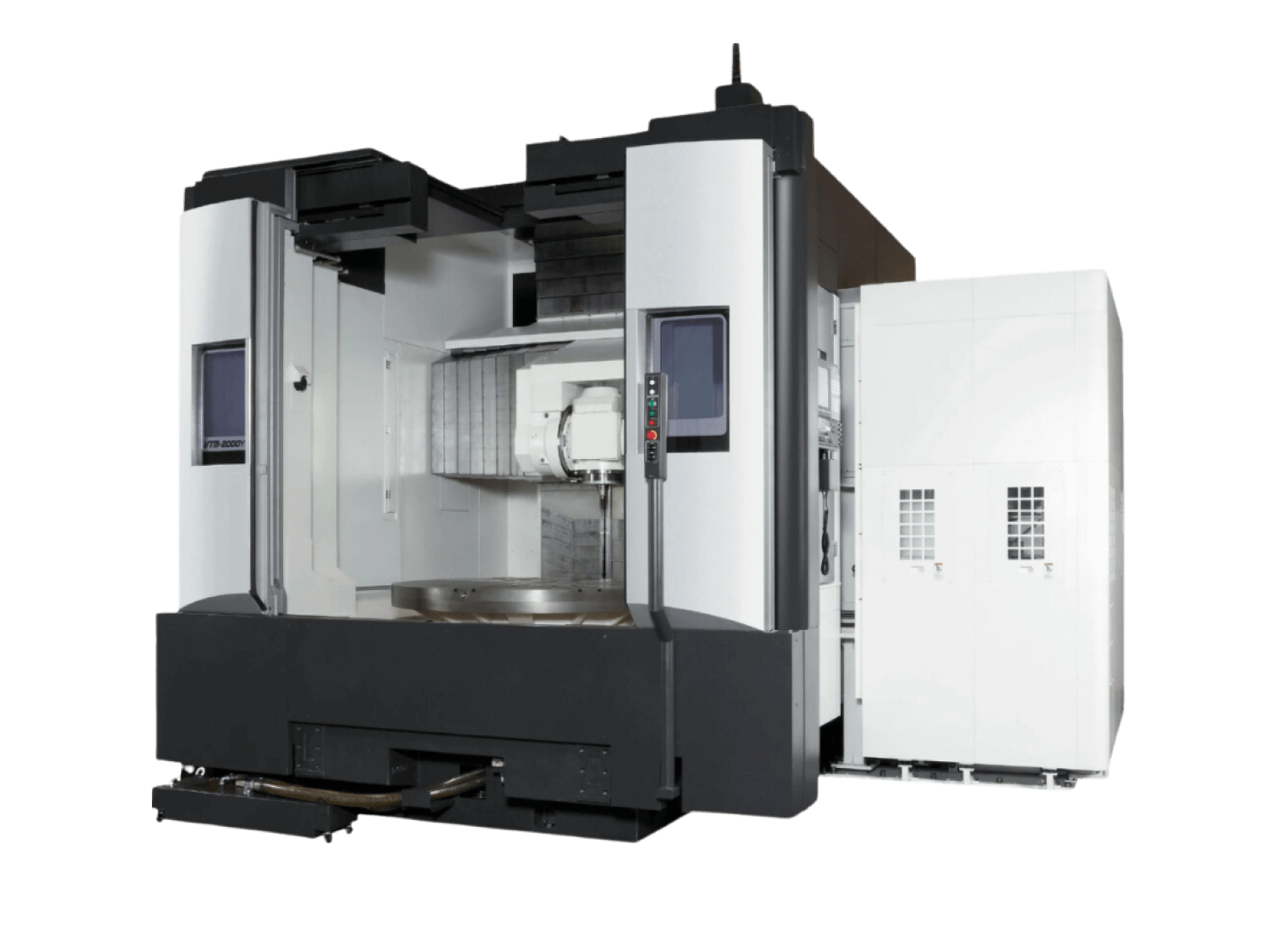

VTM-2000YB

Product description

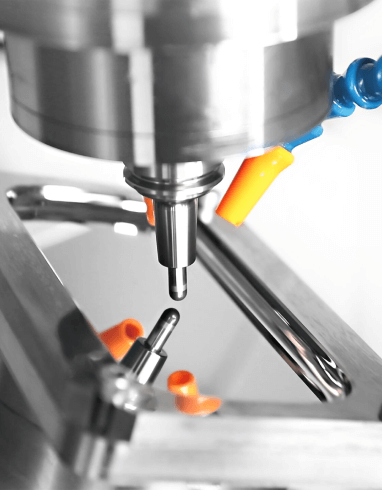

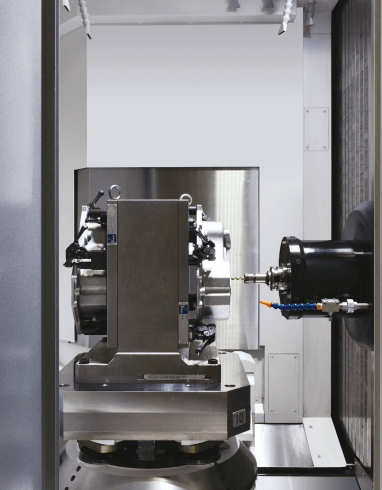

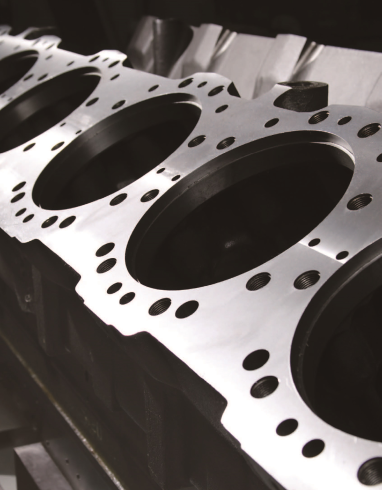

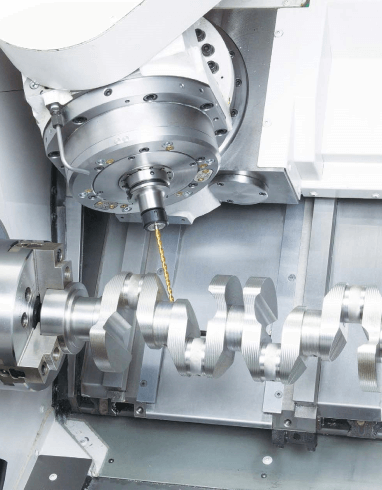

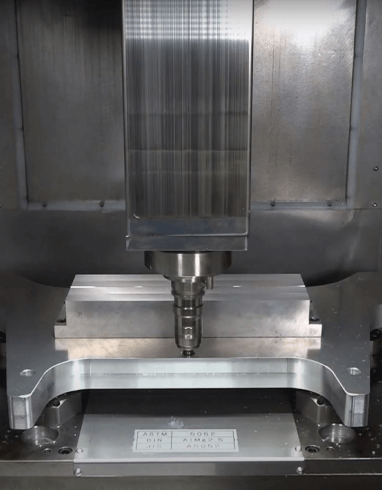

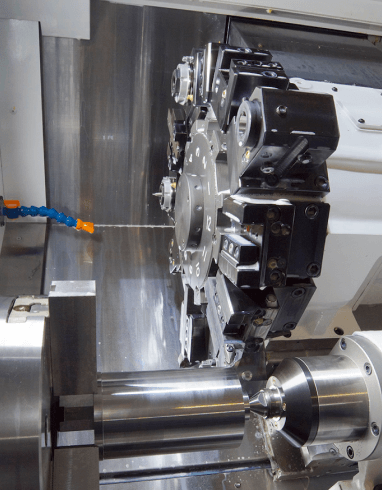

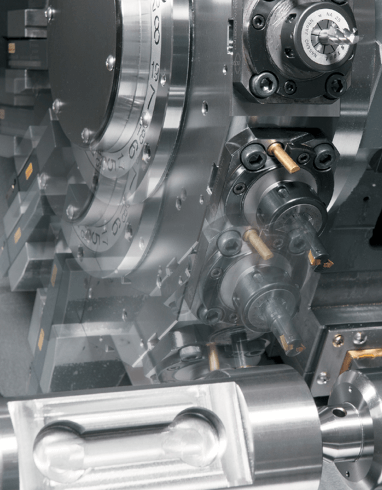

The VTM-2000YB 5-axis combination lathe/machining center can perform turning, vertical, horizontal, and angled surface machining in one operation without reorienting the part in the chuck. With operator control of spindle direction in relation to the surface of the workpiece, side cutting with straight end mills can be used to dramatically reduce cutting time compared with point cutting using ball end mills. Cutting efficiency can be increased significantly and the lifetime of the tooling can be extended, reducing overall production costs. The work spindle is supported at two locations by large diameter roller bearings, offering precision control for the production of complex parts. The spindle’s geared head generates high torque capable of sustaining the heavy cutting necessary for parts such as large valve bodies.

Industries

Aerospace

Automotive

Energy

Fluid control

Heavy Duty

Medical

Molds & Dies

Others

Key product information

Max Cutting Diameter (in)Max Cutting Diameter (mm)

Ø78.74 Ø2,000

Max Cutting Length (in)Max Cutting Length (mm)

55,12 1.400

Spindle Speed (min-1)

4~300 [4~200]

Spindle Power (30 min/cont) (hp)Spindle Power (30 min/cont) (kW)

40/30 30/22

X-Axis Travel (in)X-Axis Travel (mm)

62,99 1.600

Y-Axis Travel (in)Y-Axis Travel (mm)

62.99 <±31.50> 1,600 <±800>

Z-Axis Travel (in)Z-Axis Travel (mm)

55,12 1.400

Rapid Traverse - X:Y:Z (fpm)Rapid Traverse - X:Y:Z (m/min)

105 32

Rapid Traverse - C:B (min⁻¹)

19.5 : 20

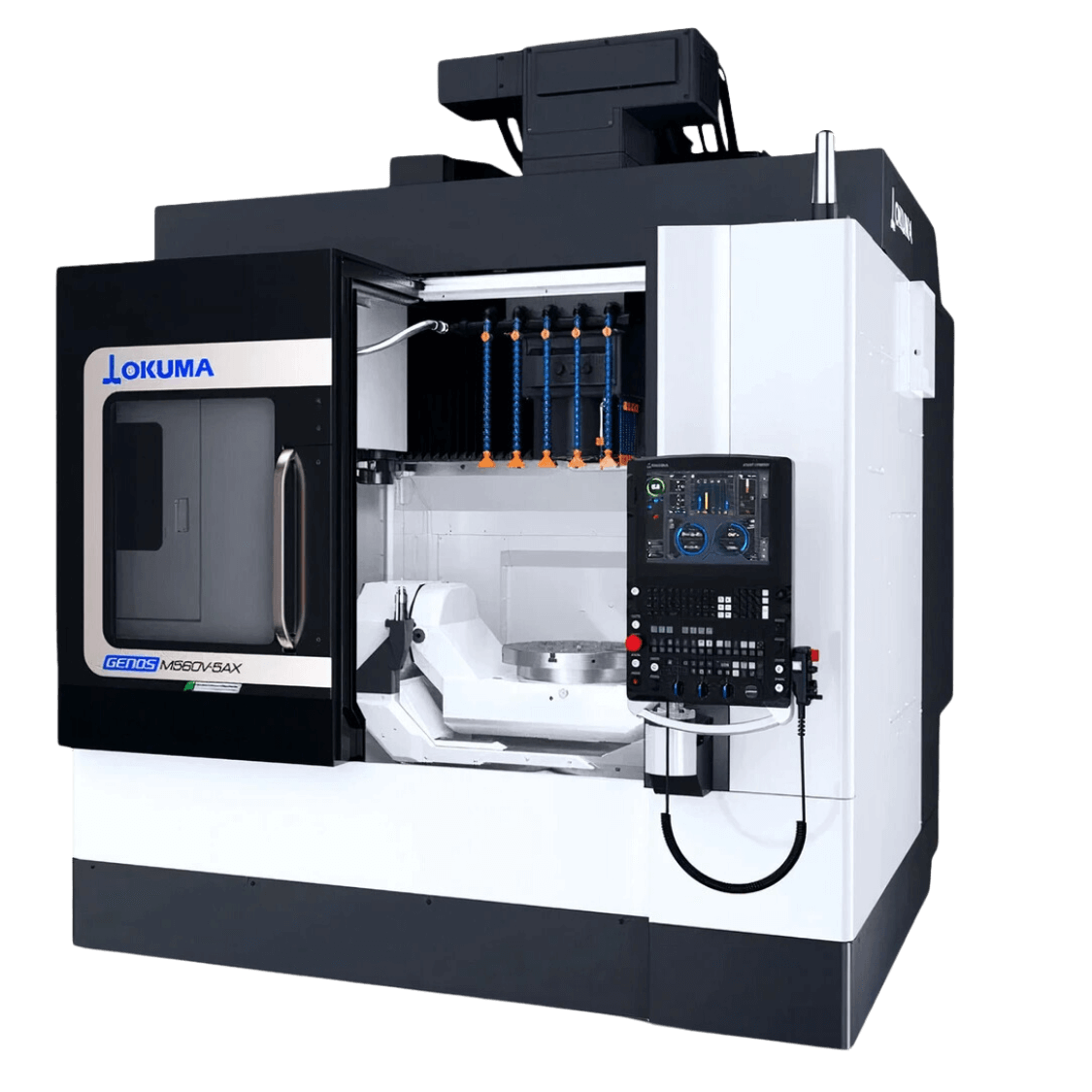

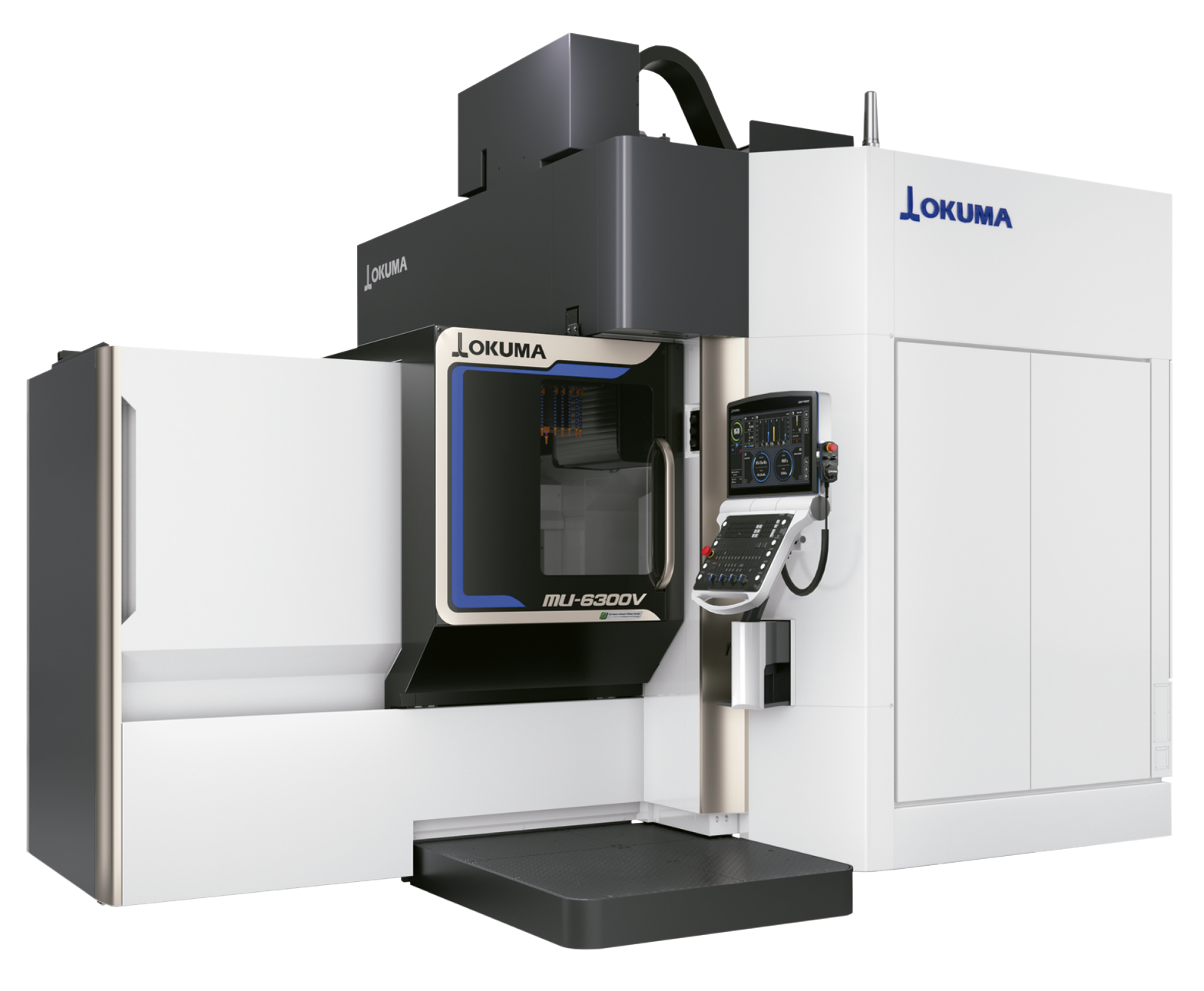

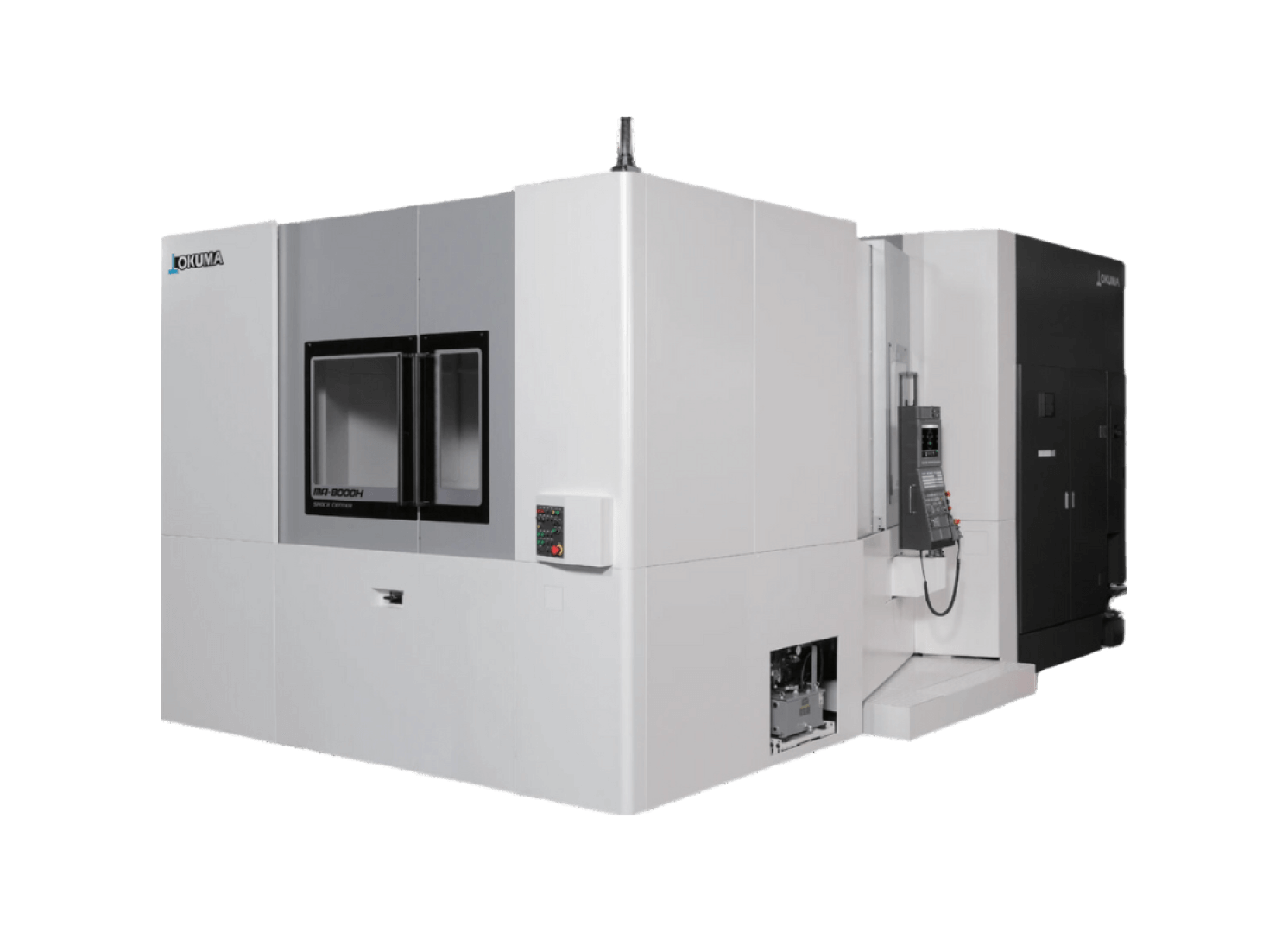

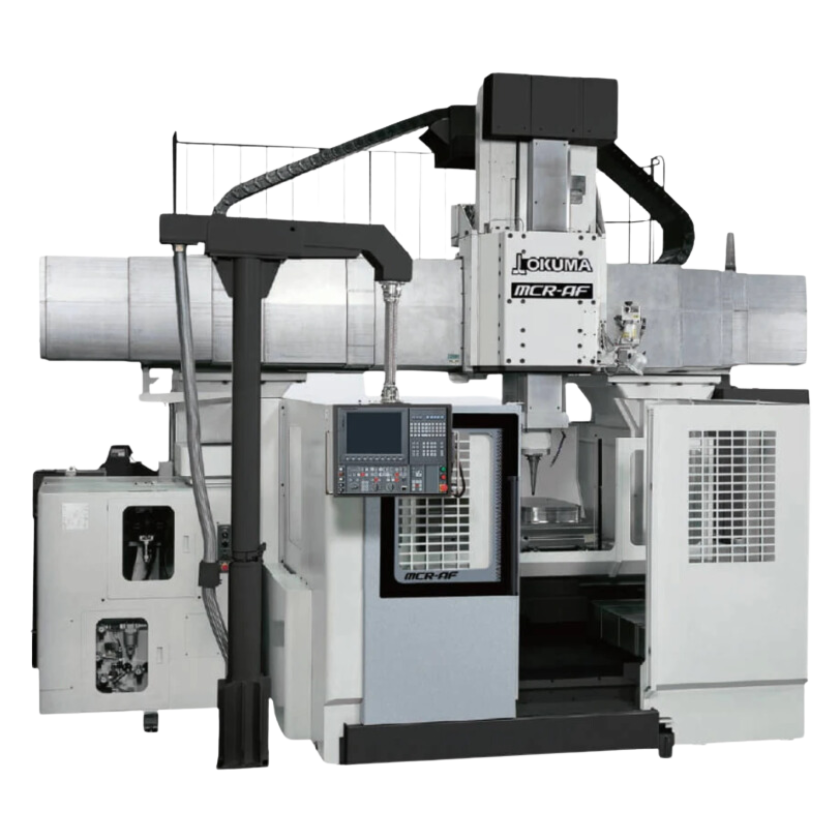

Frequent combinations to improve your processes in CNC Lathes, CNC Machining Centers, and other Machining Equipment.

Equip and maximize the productivity of your CNC machines with comprehensive solutions.

Accessories and peripherals

Mist collector

Cooling system

Coolant filtration equipment and magnetic separator

Learn more about PERIFERIQ

Design and development of industrial automation tailored to your needs

Automatic doors

Automated loading and unloading systems

Safety and cleaning systems

Interfaces for external workholding systems

Learn more about OTOMATIQA