MODIG

MODIG

IM10T

Product description

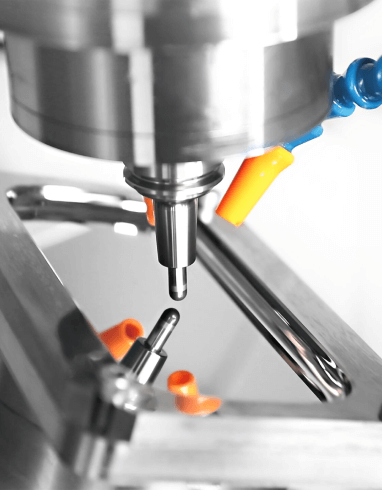

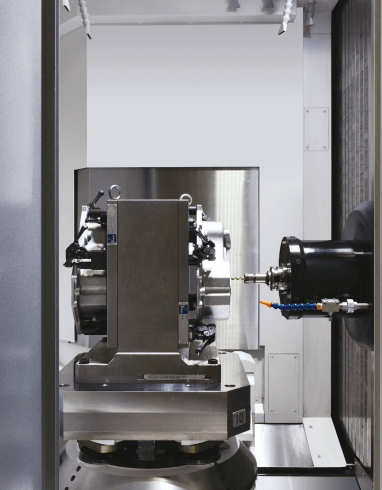

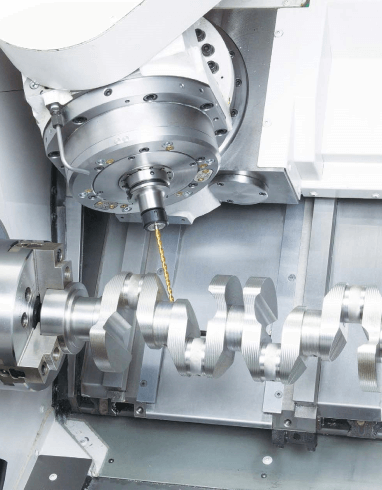

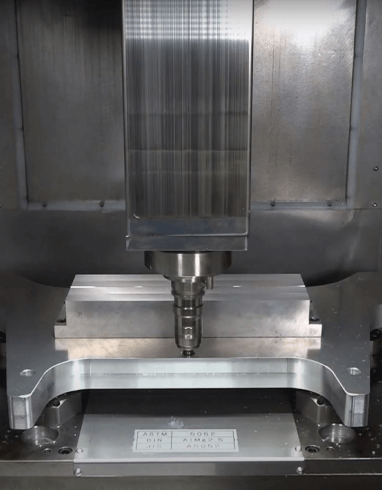

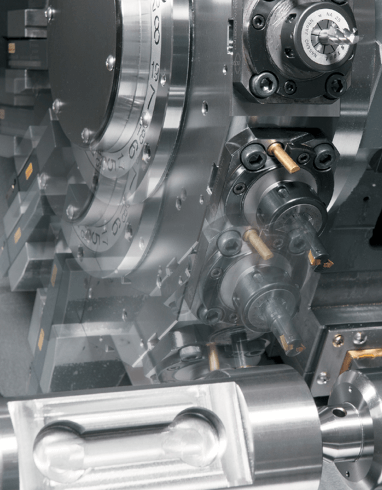

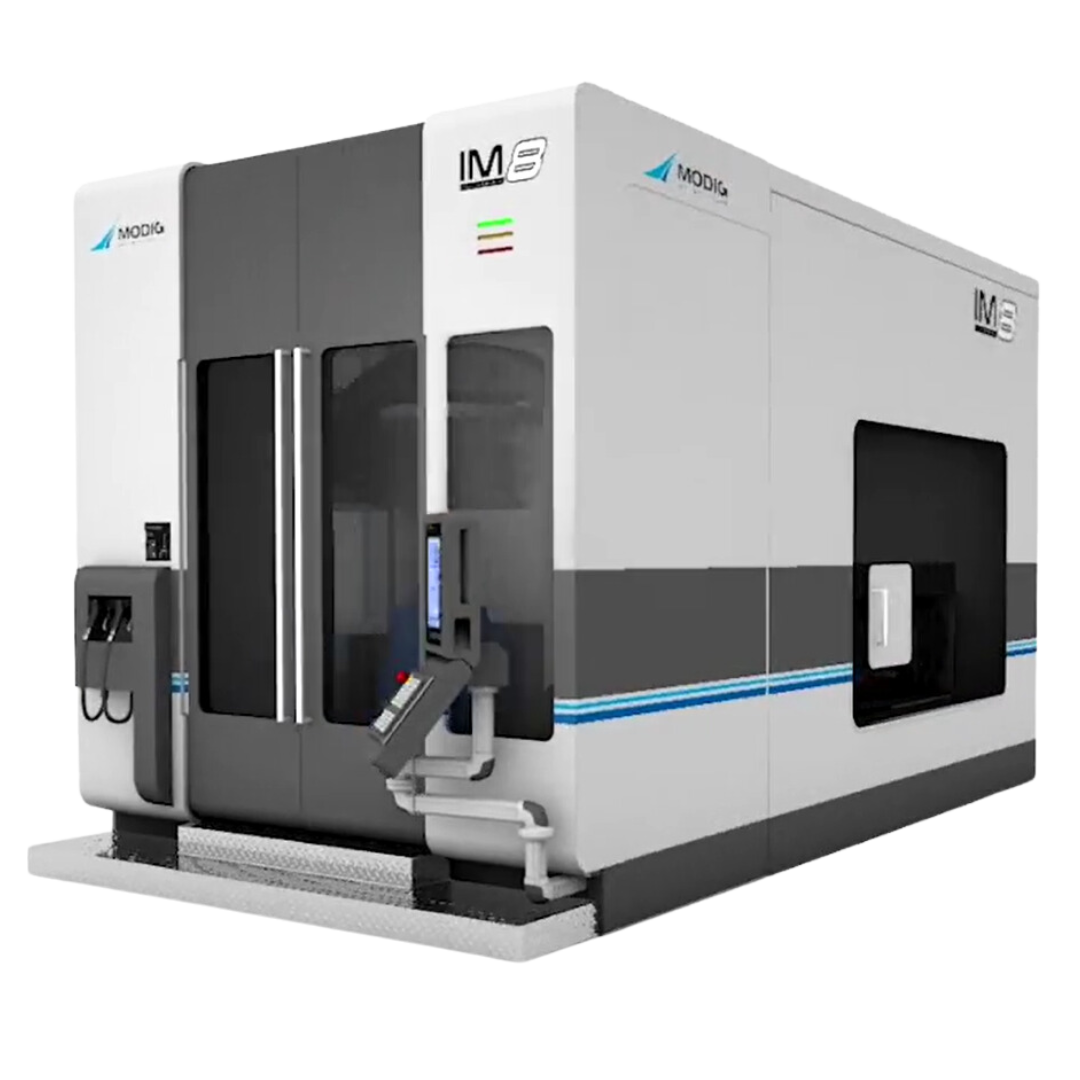

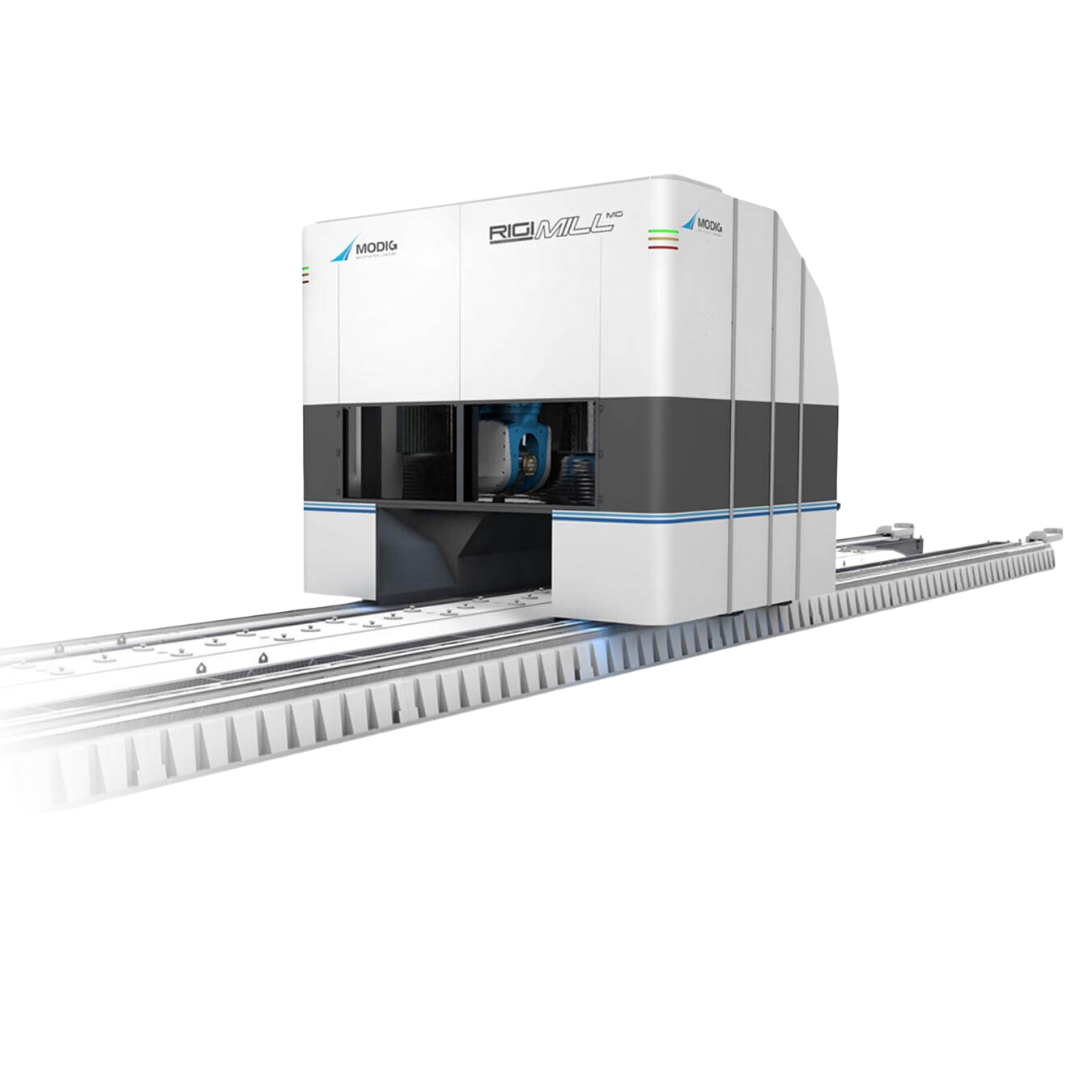

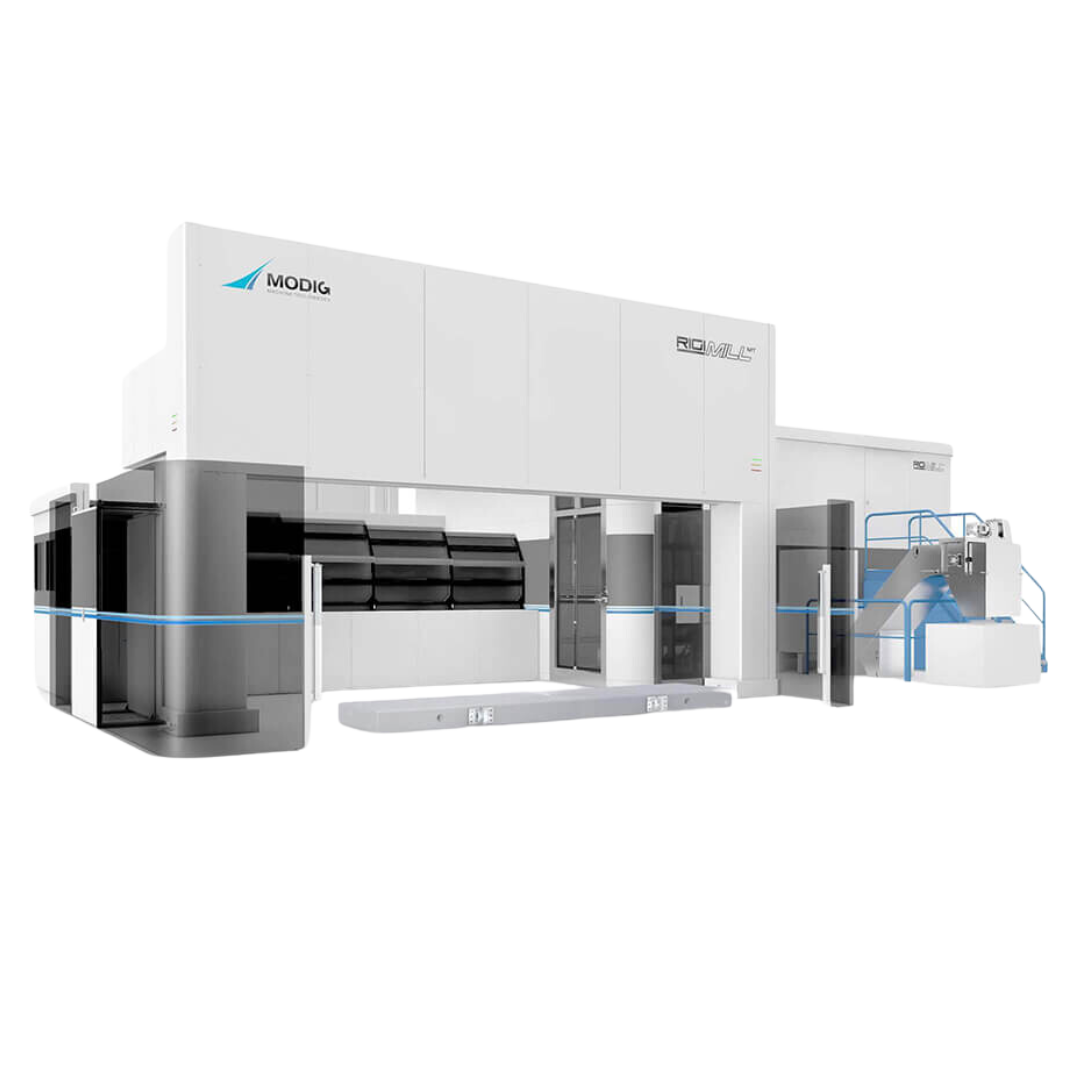

Modig's IM-machine series was born to meet the demands of today's manufacturing, characterized by ever-narrower, more complex and component-intensive parts and shorter production times. With a patented single-spindle design of up to 200 hp (150 kW) working from below, this High-Speed Inverted Machining Center sets a new standard for 5-axis machining.

Its fast cutting times make this machine ideal for those industries characterized by high volumes, short lead times and complex parts. A cast iron base around the frame, locked at all four corners, makes the machine extremely rigid, allowing the tool to work with extreme precision. In addition, the inverted machining facilitates burr evacuation with lower coolant consumption and higher efficiency.

Industries

Aerospace

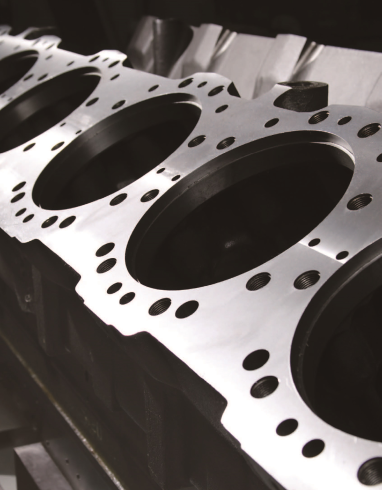

Automotive

Heavy Duty

Others

Product highlights

Trunnion Board (in)Trunnion Board (mm)

401000

Maximum part size (in)/ diameter (in)Maximum part size (mm)/ diameter (mm)

37 x 30 x 22 / 47950 x 750 x 550 / 1200

Travel (X / Y / Z / C / A) [in]Travel (X / Y / Z / C / A) [mm]

47 / 47 / 47 / 300° / 360°1200 / 1200/ 1200/ (±120° + 60°) /continuous

Maximum part height (in)Maximum part height (mm)

35900

Inference of maximum part size ø diameter (in)Inference of maximum part size ø diameter (mm)

471200

Standard Spindle (Speed) [rpm]

20,000

Tool changer (# Tools)

60 / 120

Tool changer (Tool taper)

HSK-63A

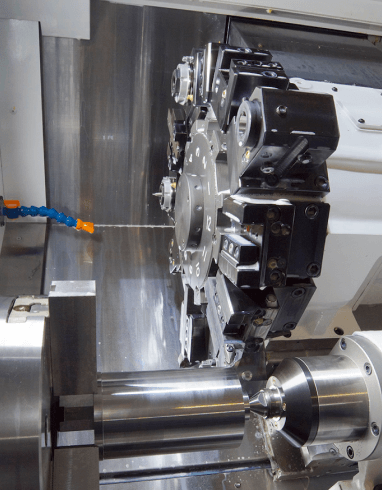

Lathe-mill speed (rpm)

1000

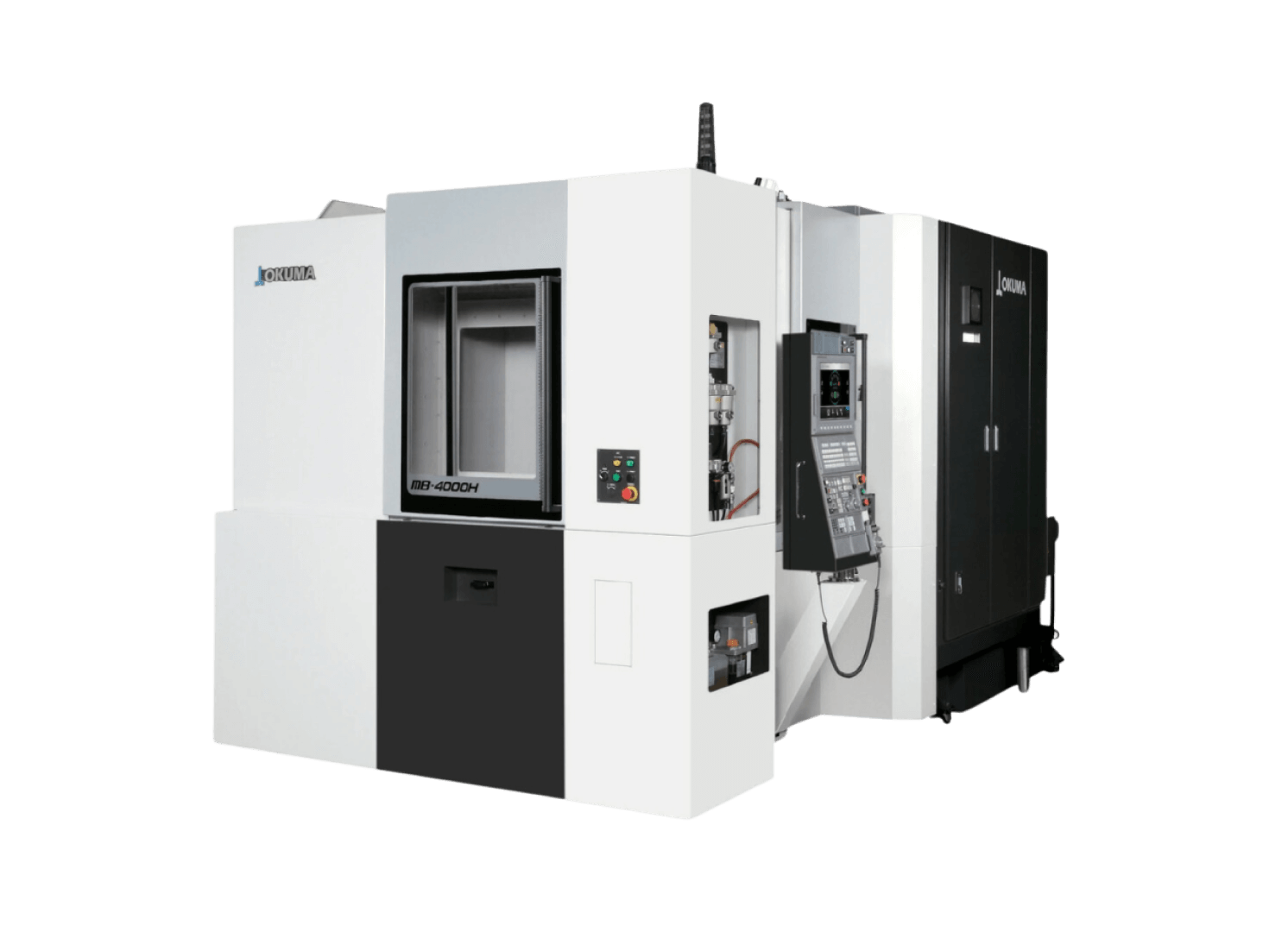

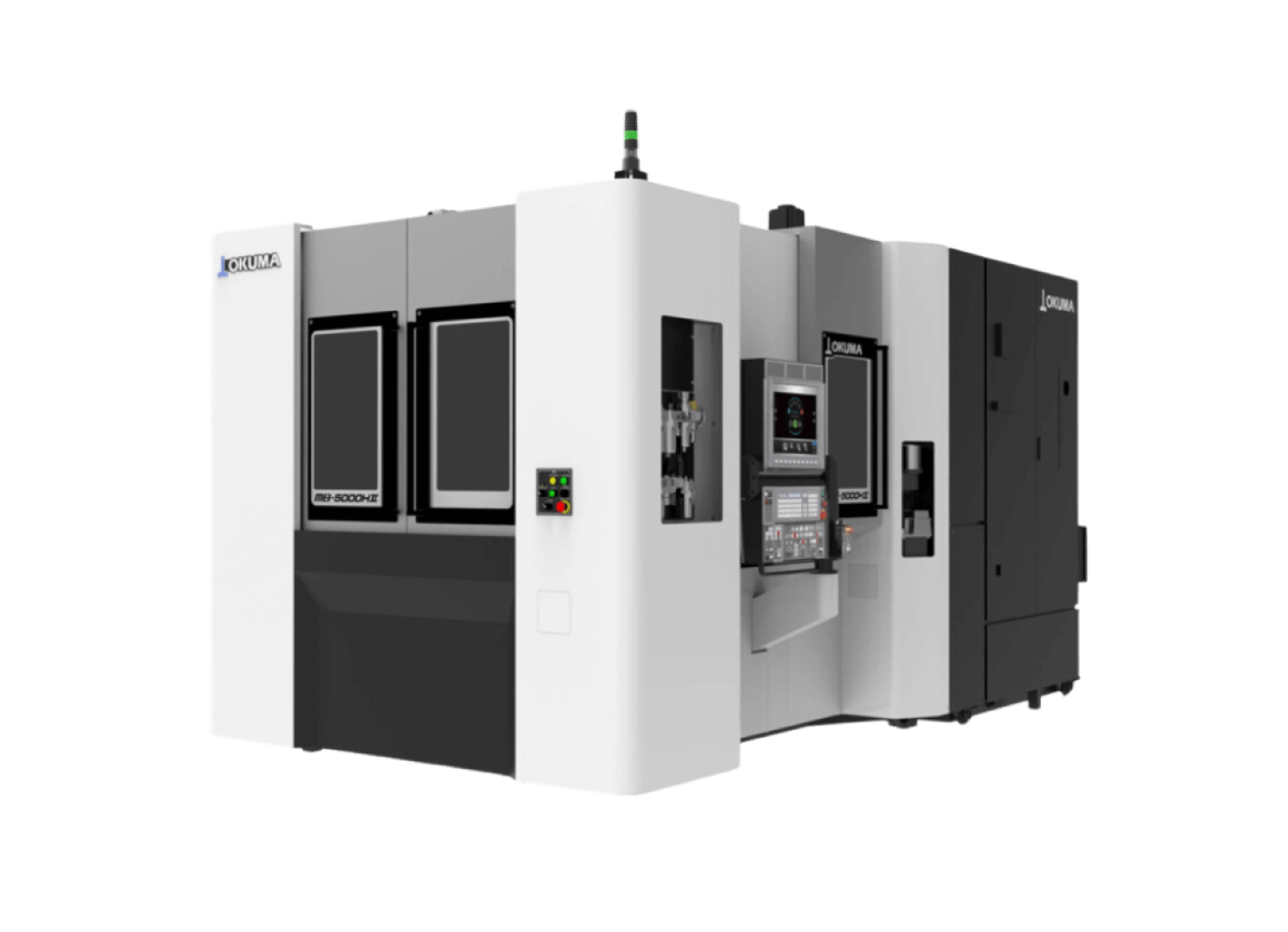

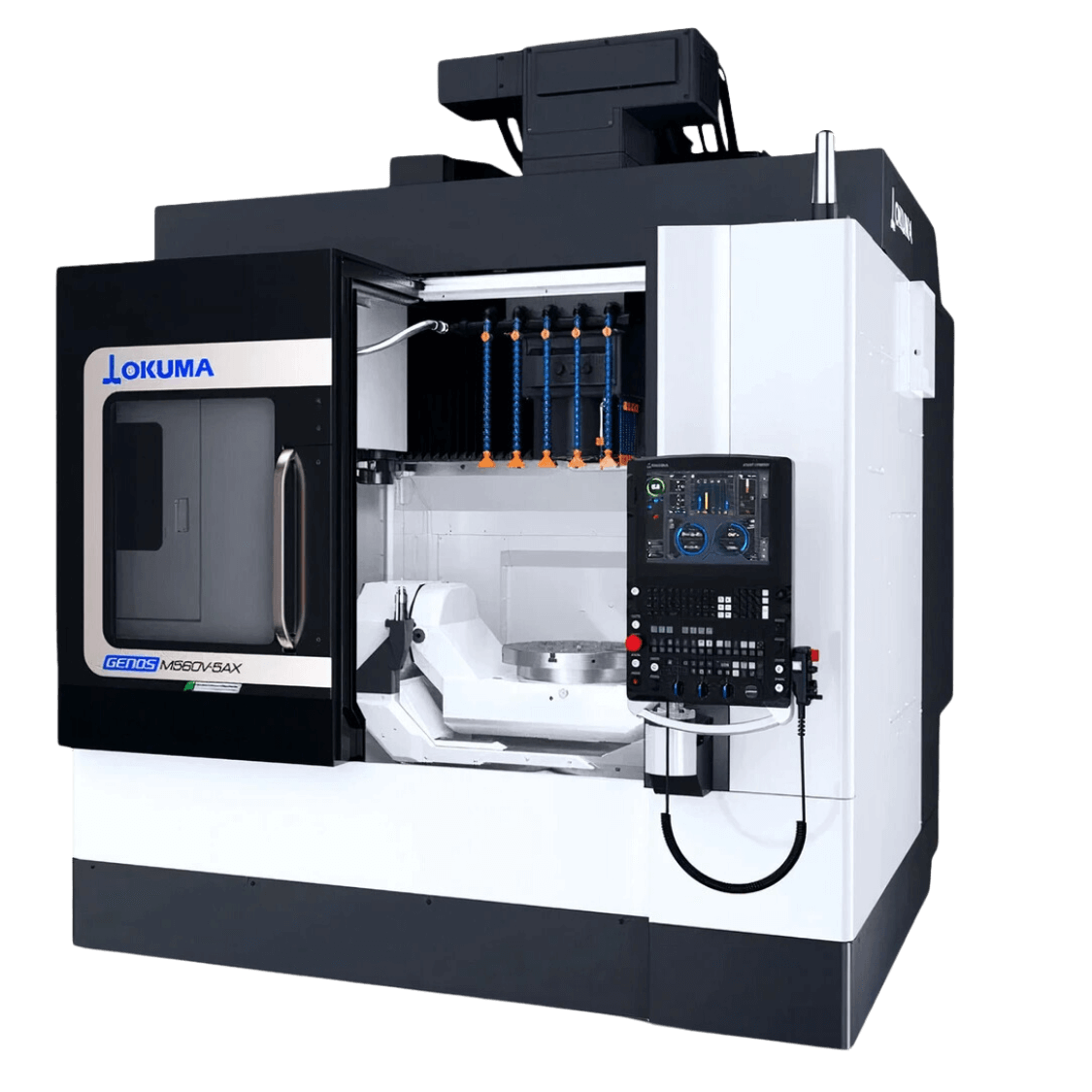

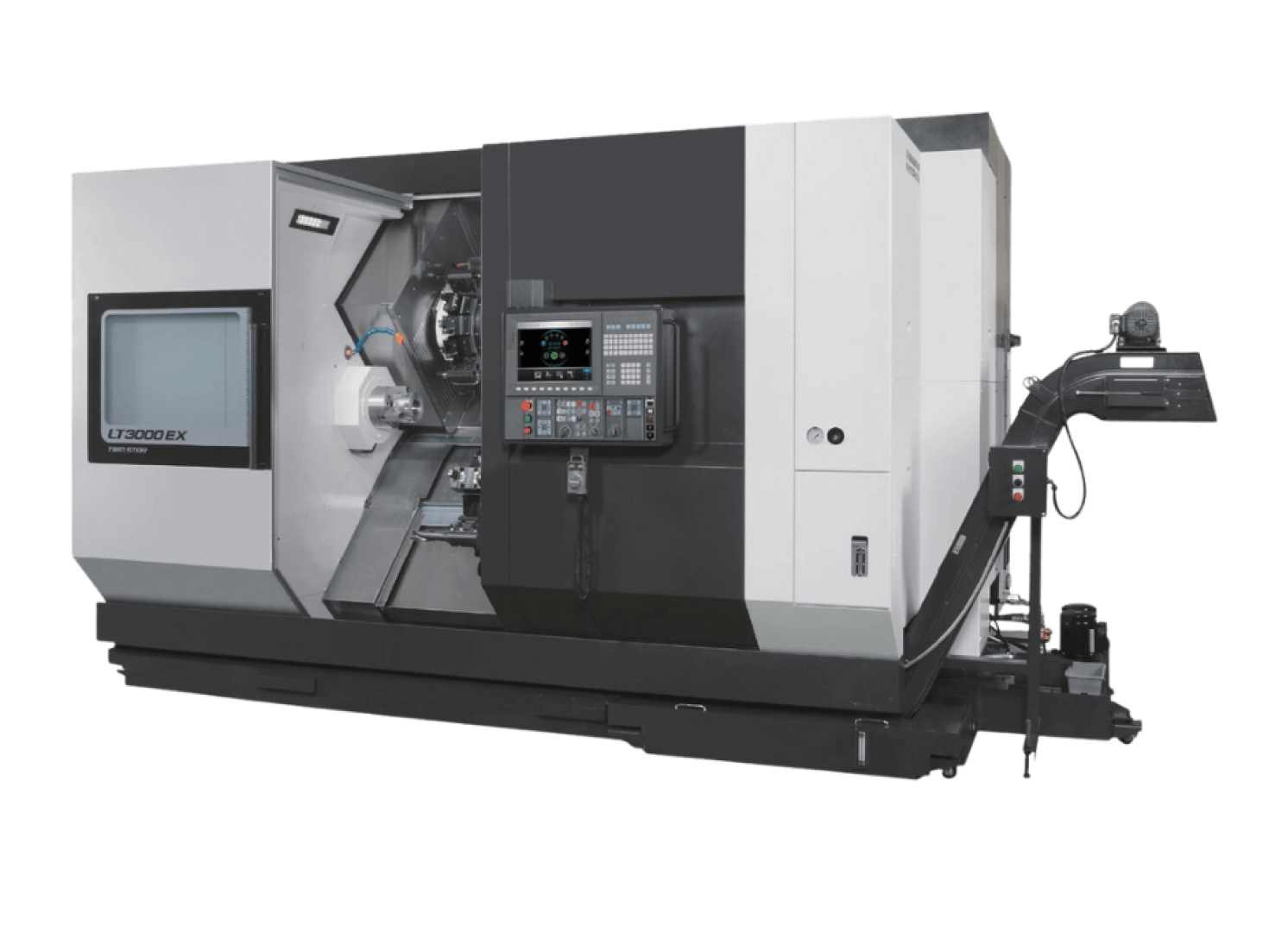

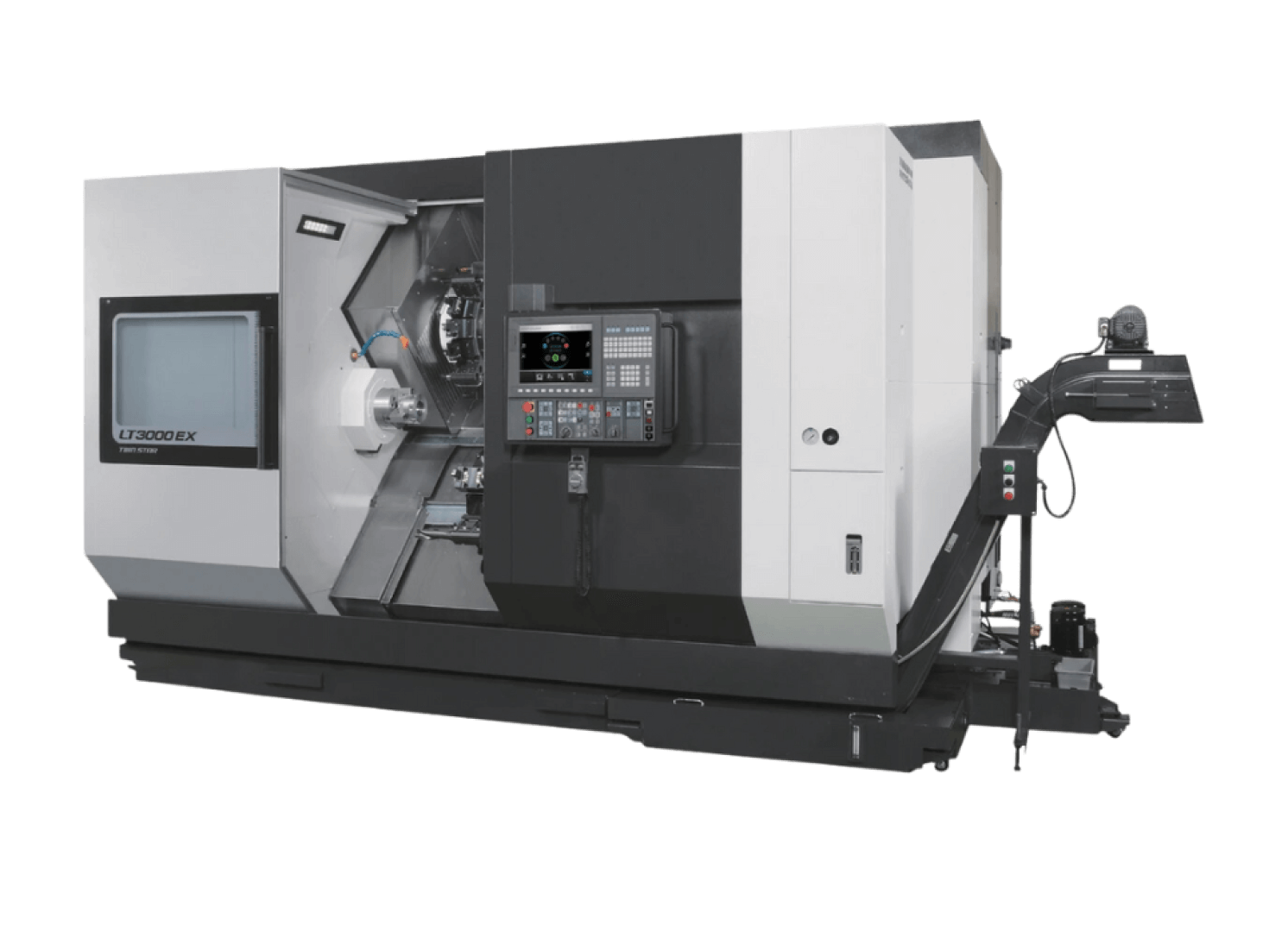

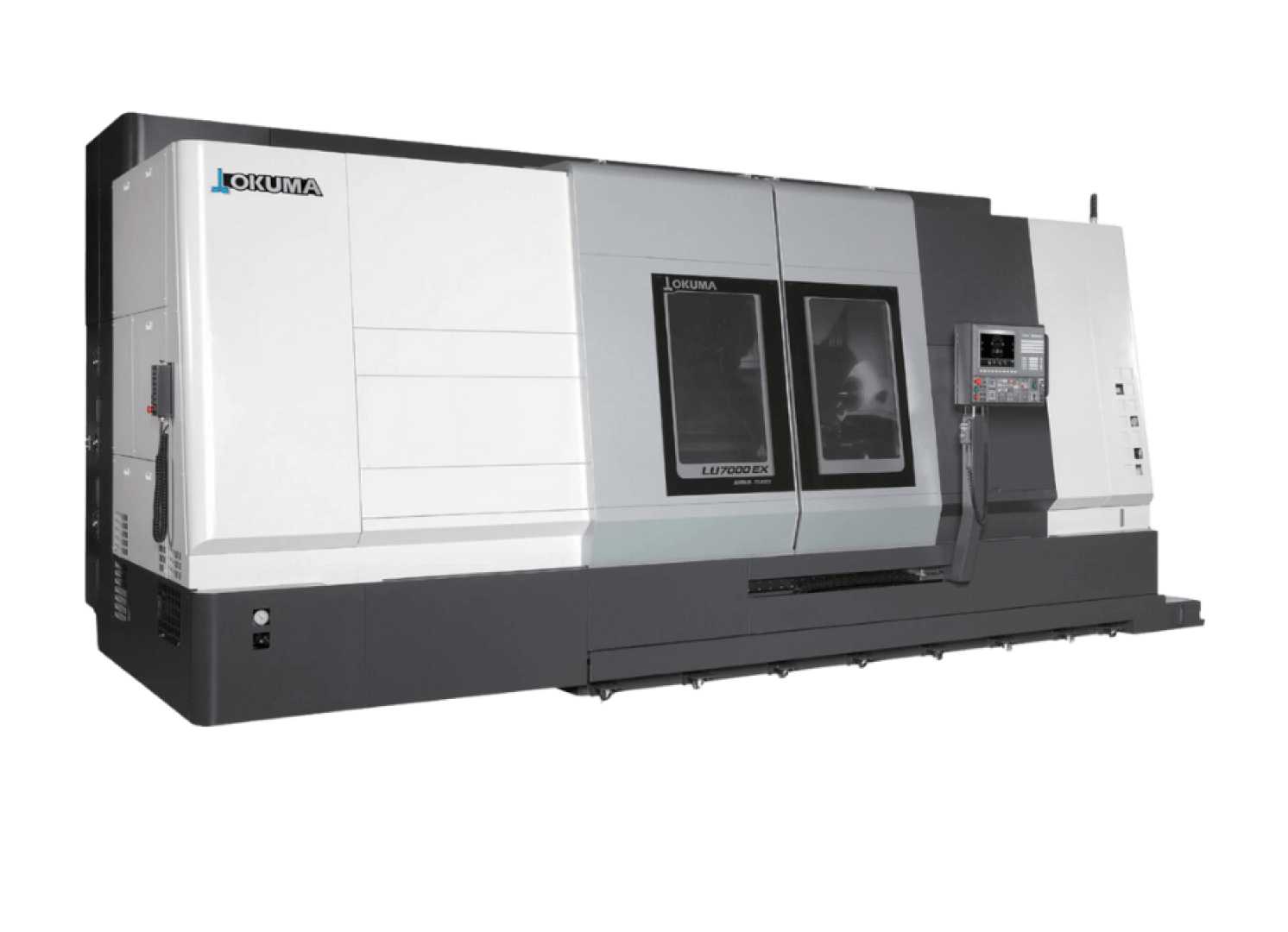

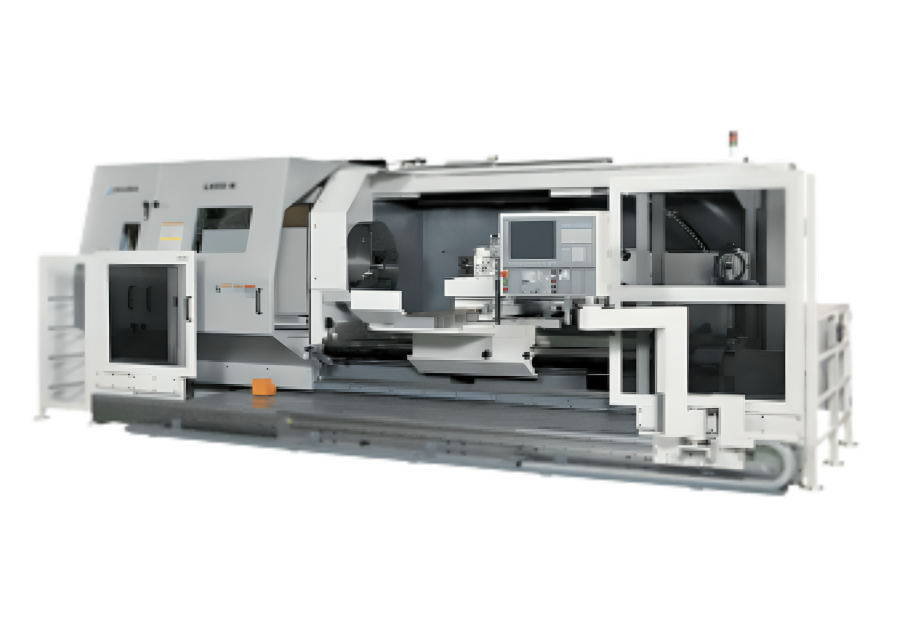

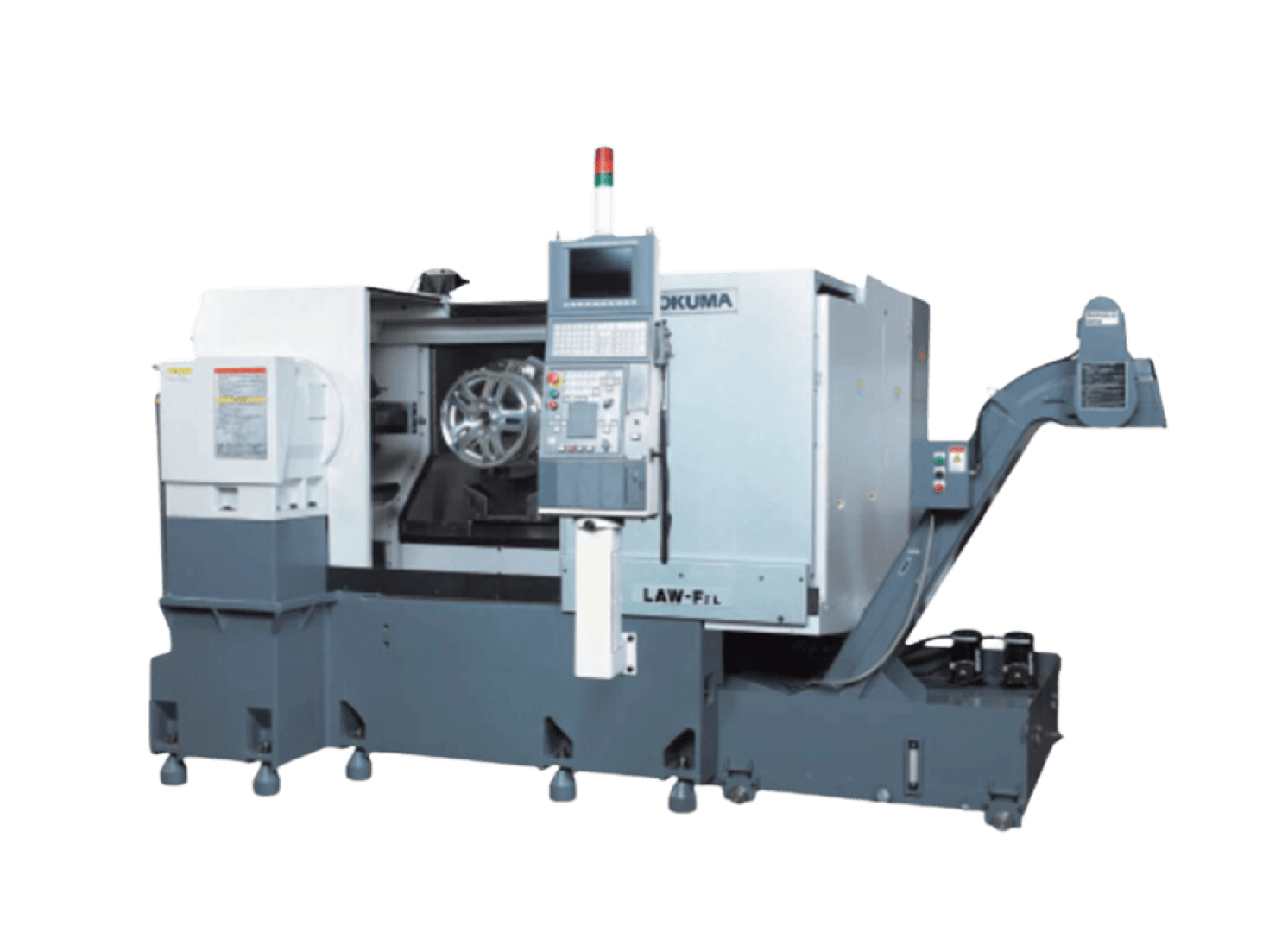

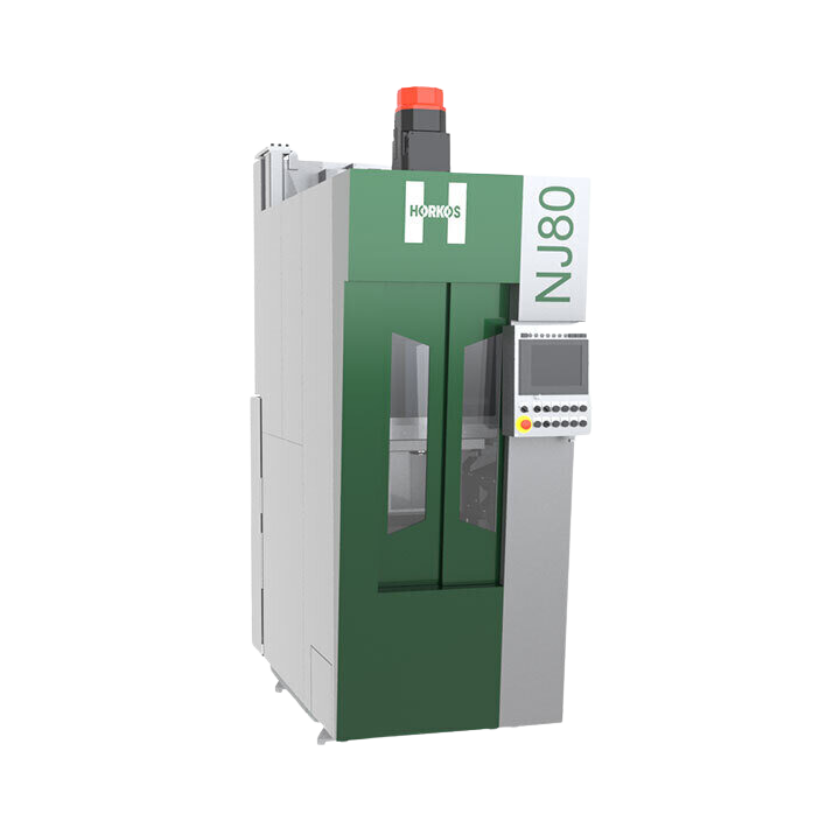

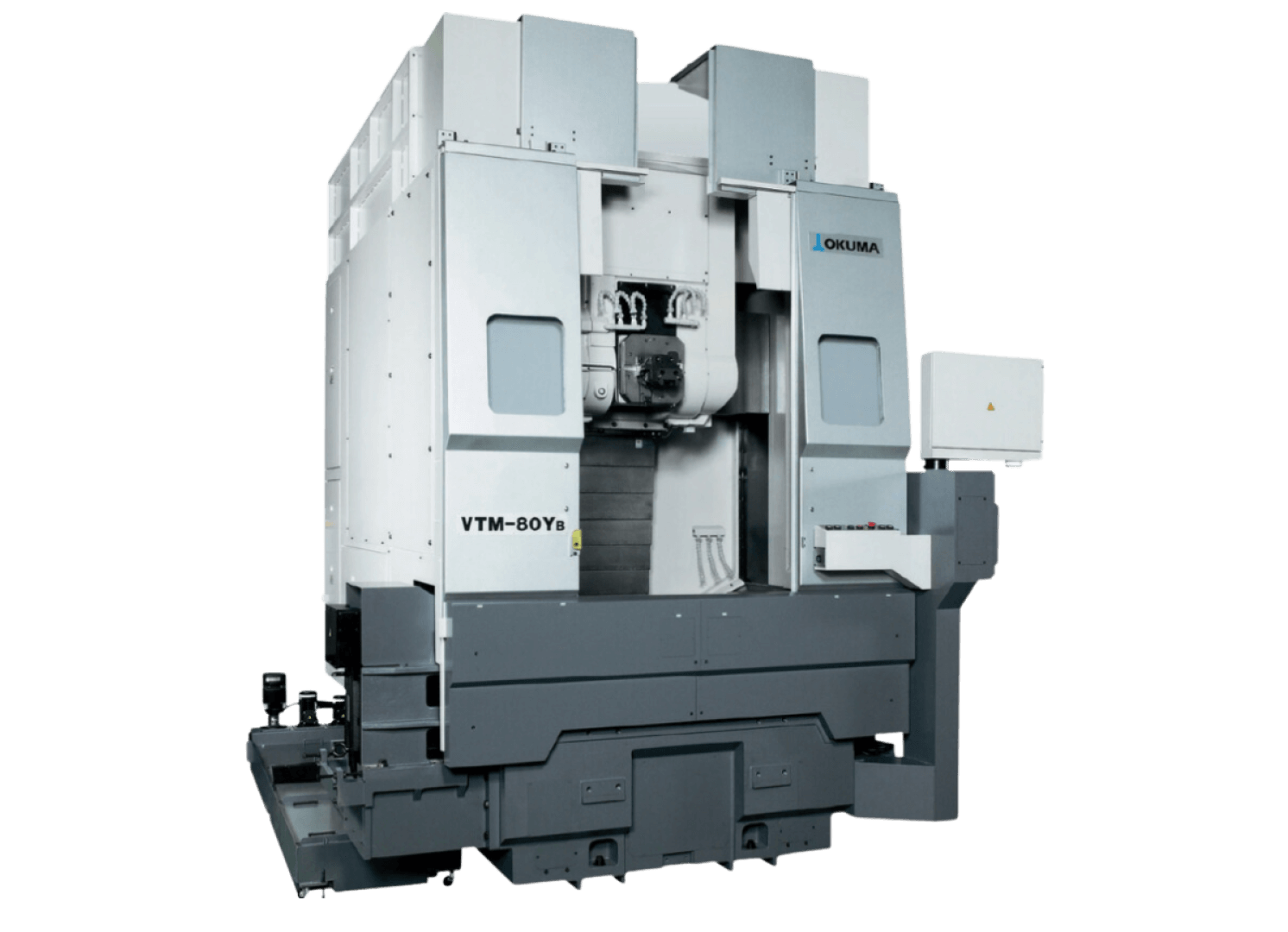

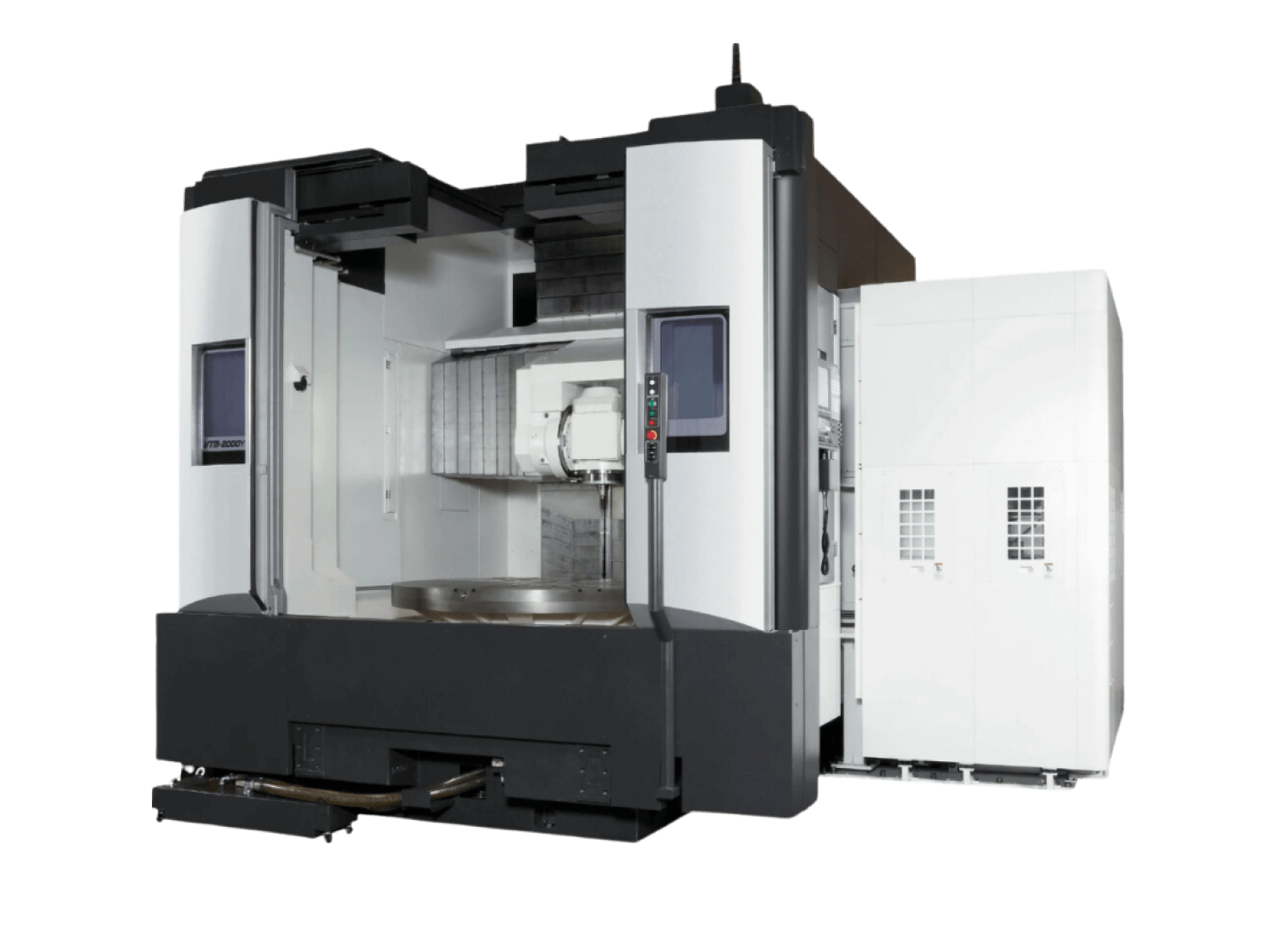

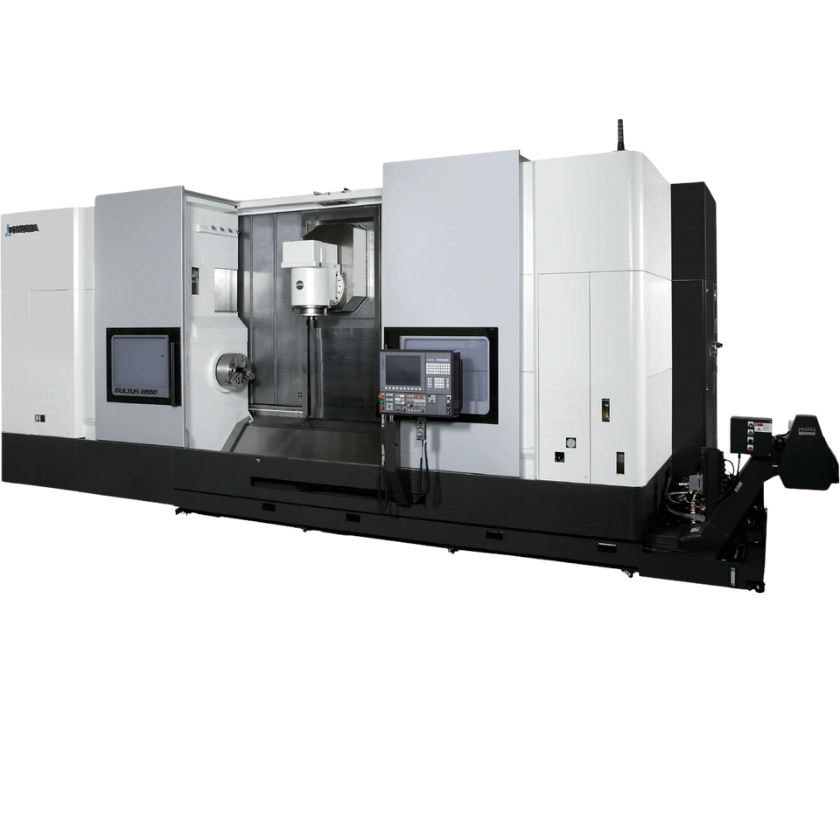

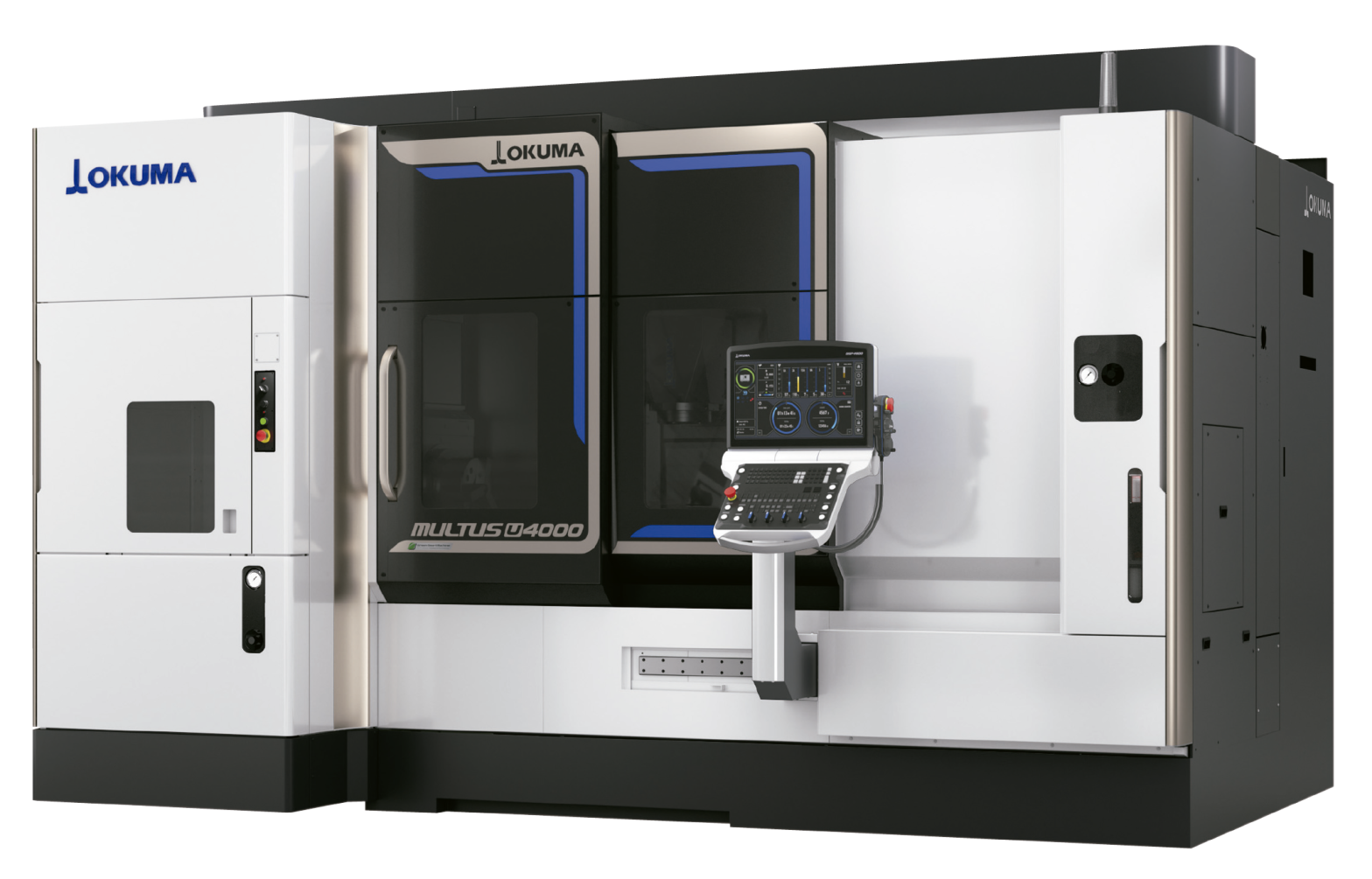

Combinaciones frecuentes para mejorar tus procesos en Tornos CNC, Centros de Maquinado CNC y demás Equipo para Mecanizado.

Equipe y maximice la productividad de sus Máquinas CNC con soluciones integrales

Creación y desarrollo de automatización industrial a la medida de sus necesidades