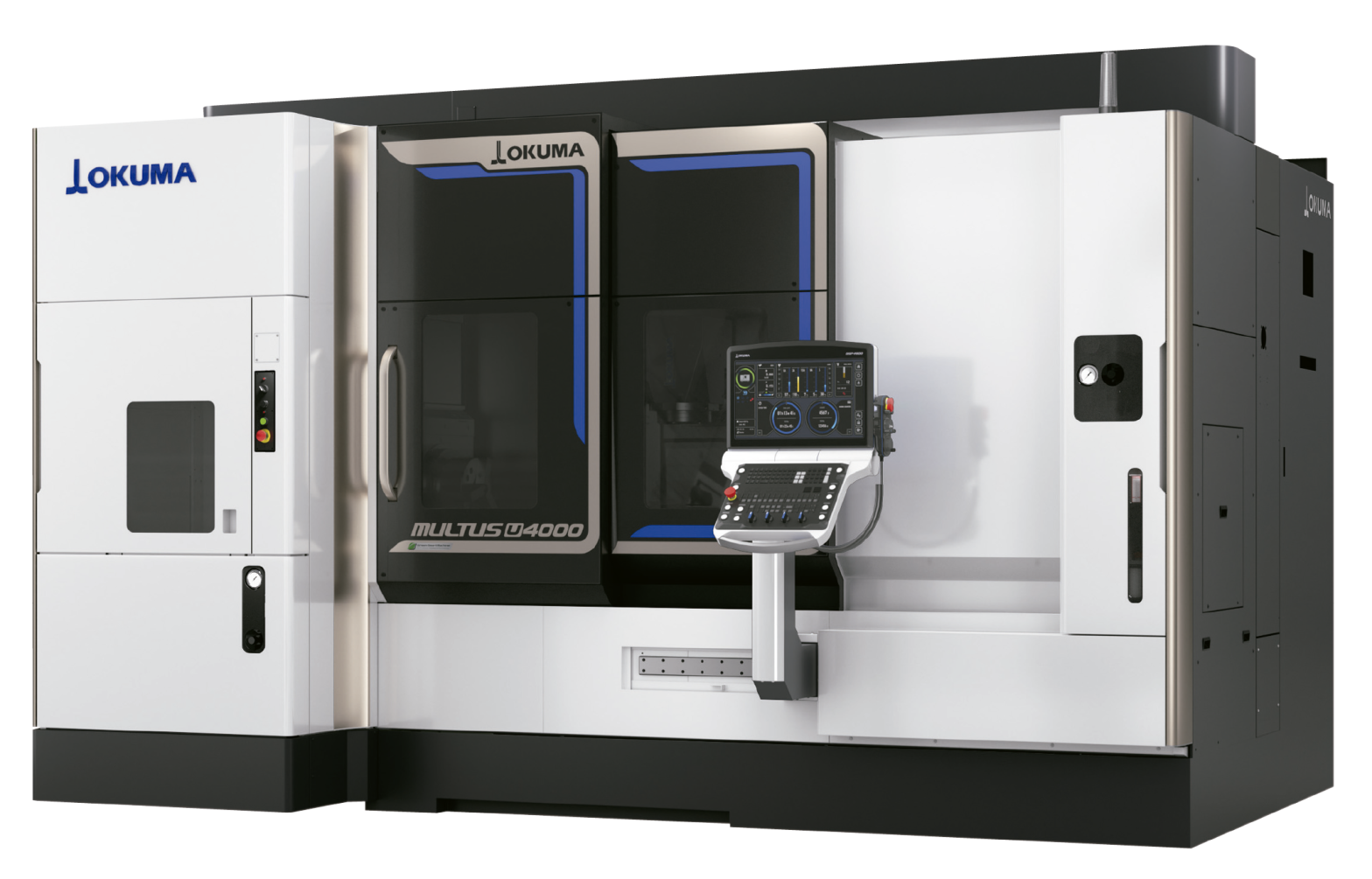

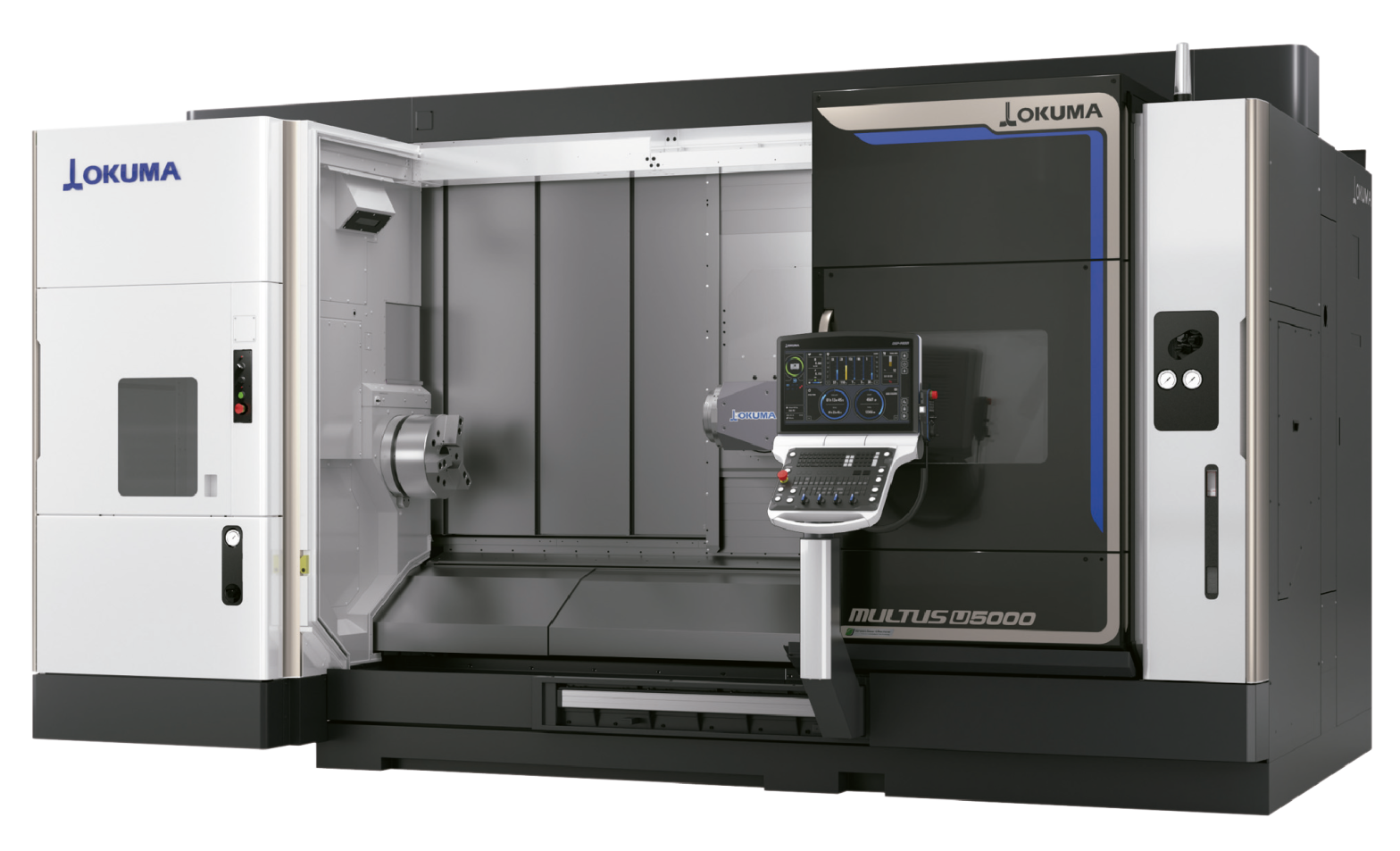

OKUMA

OKUMA

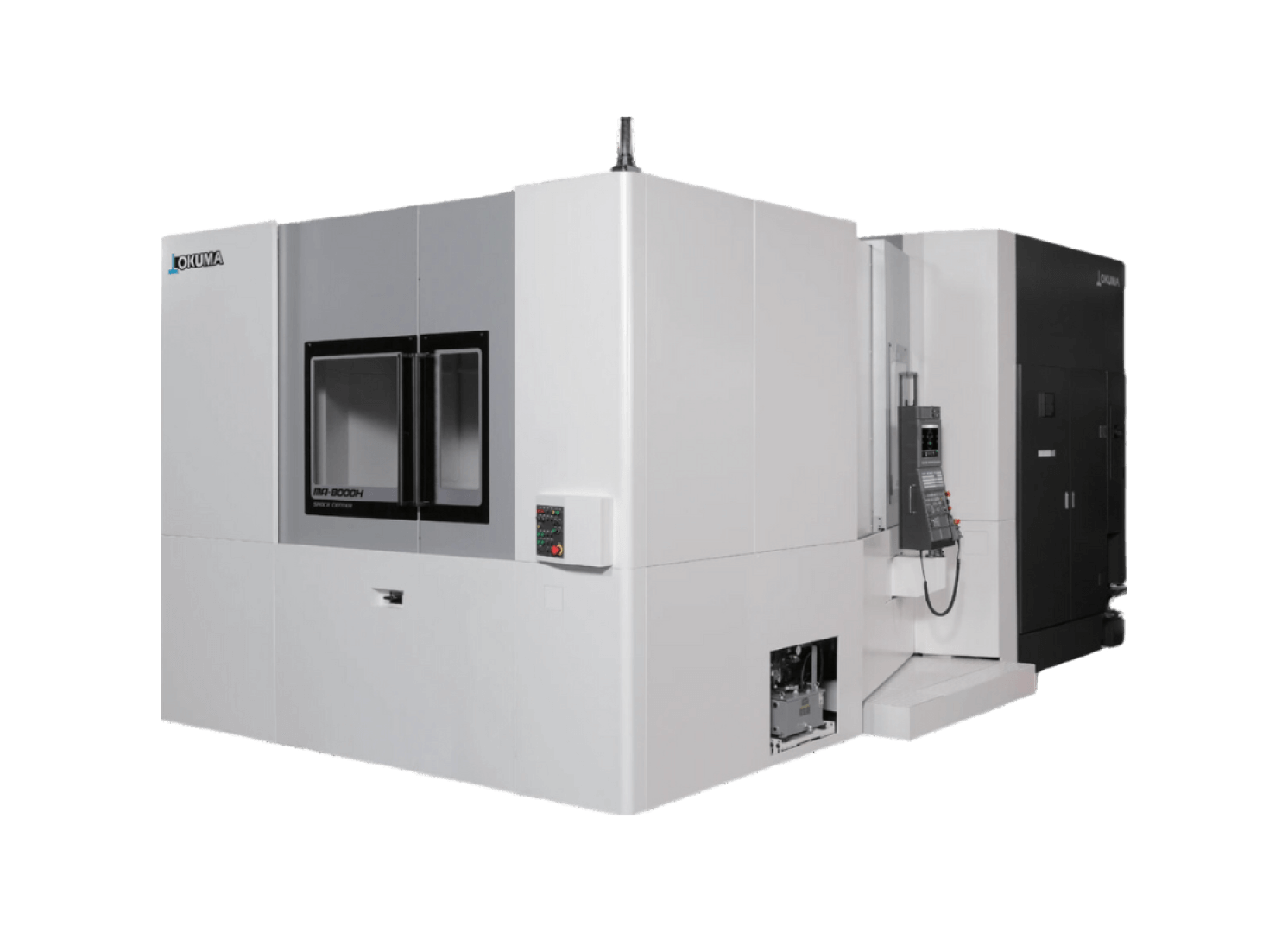

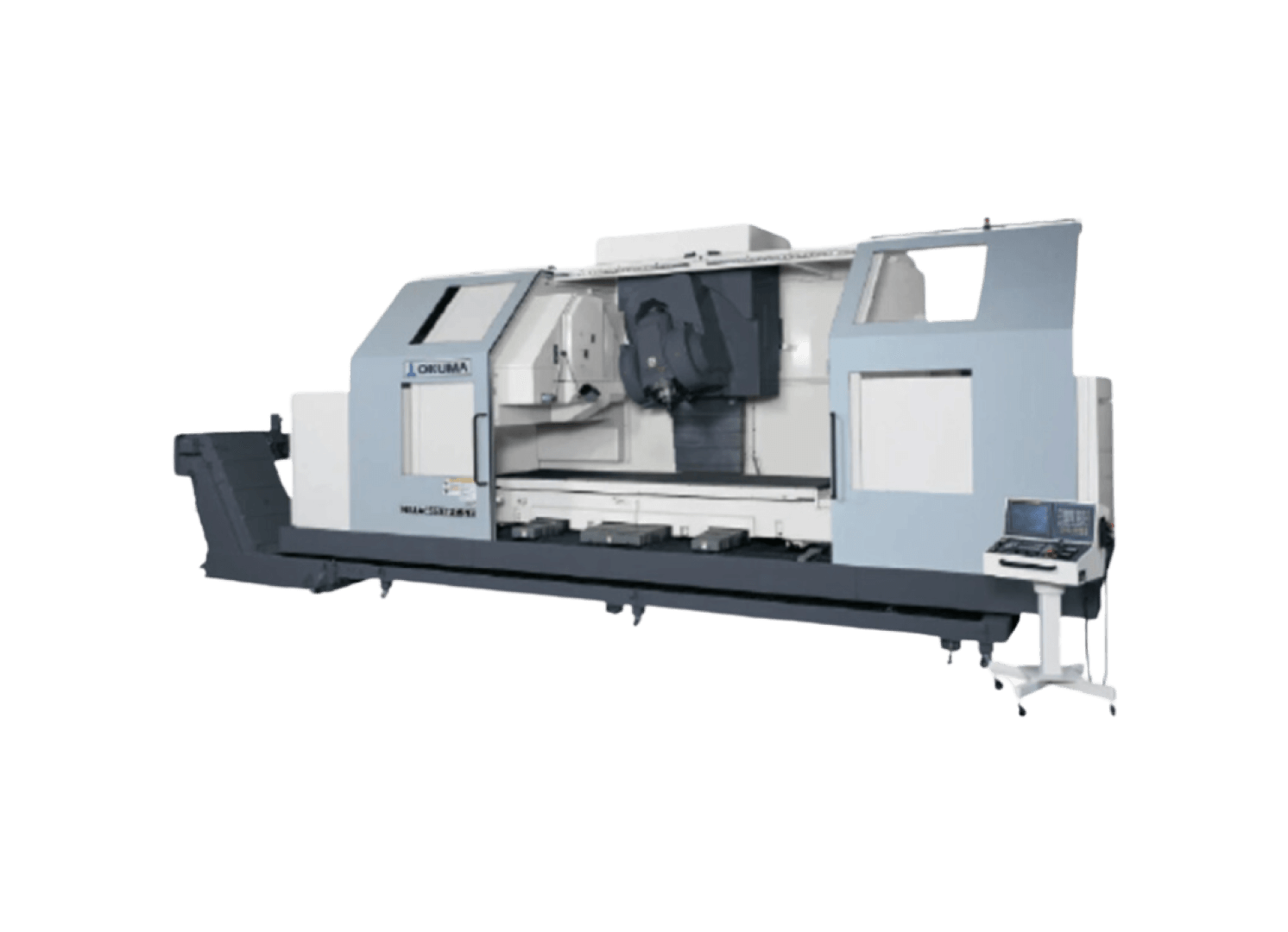

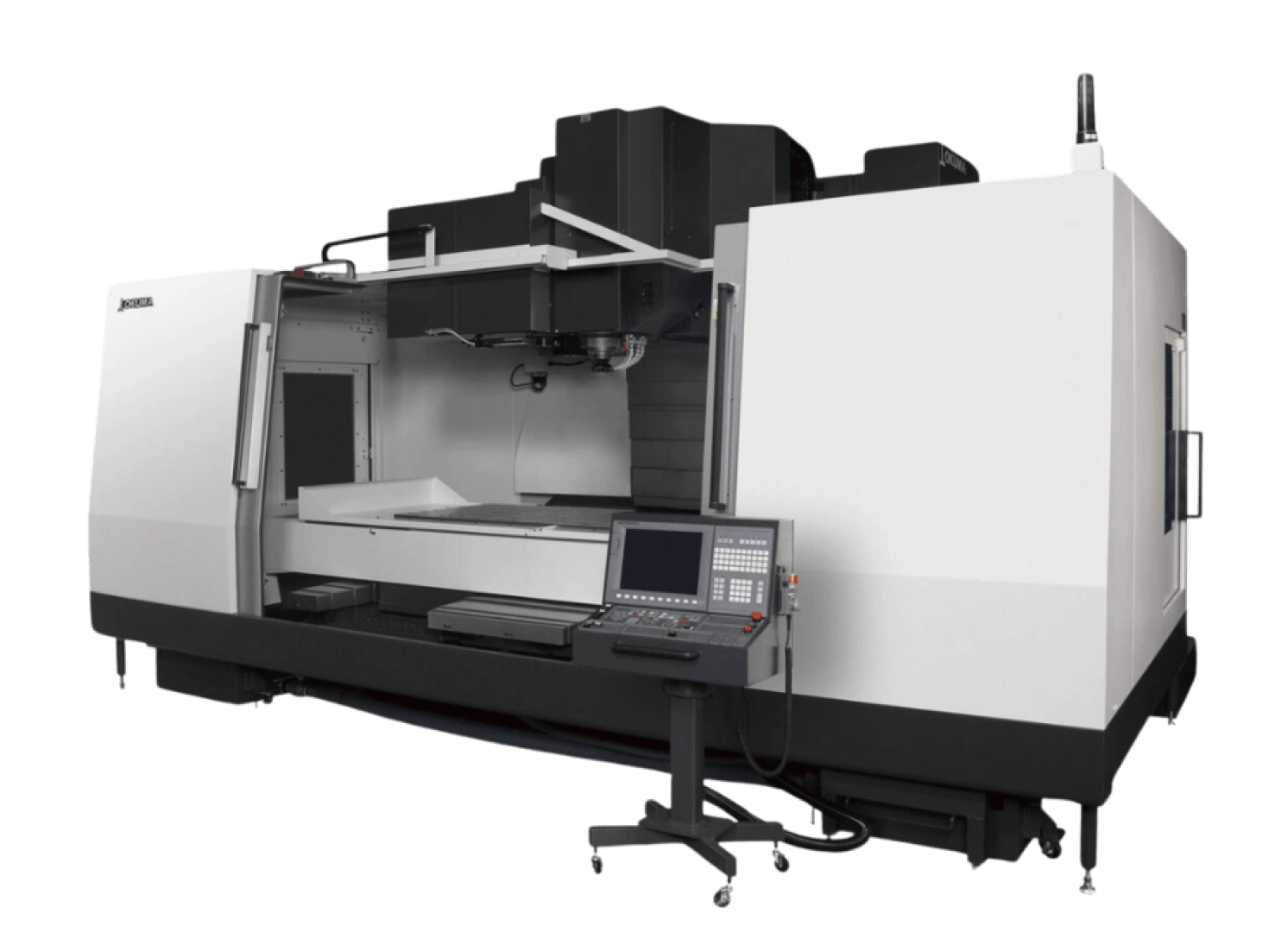

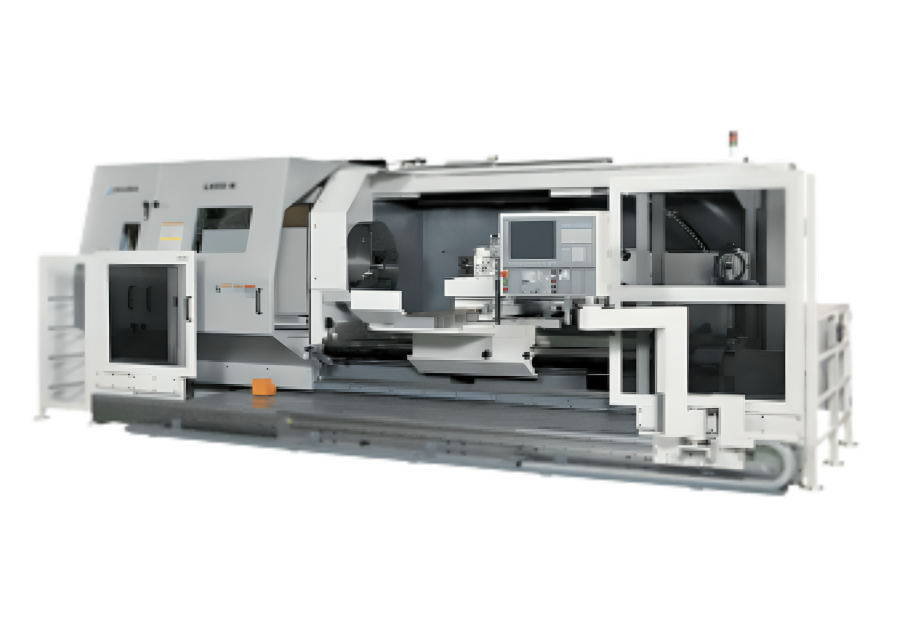

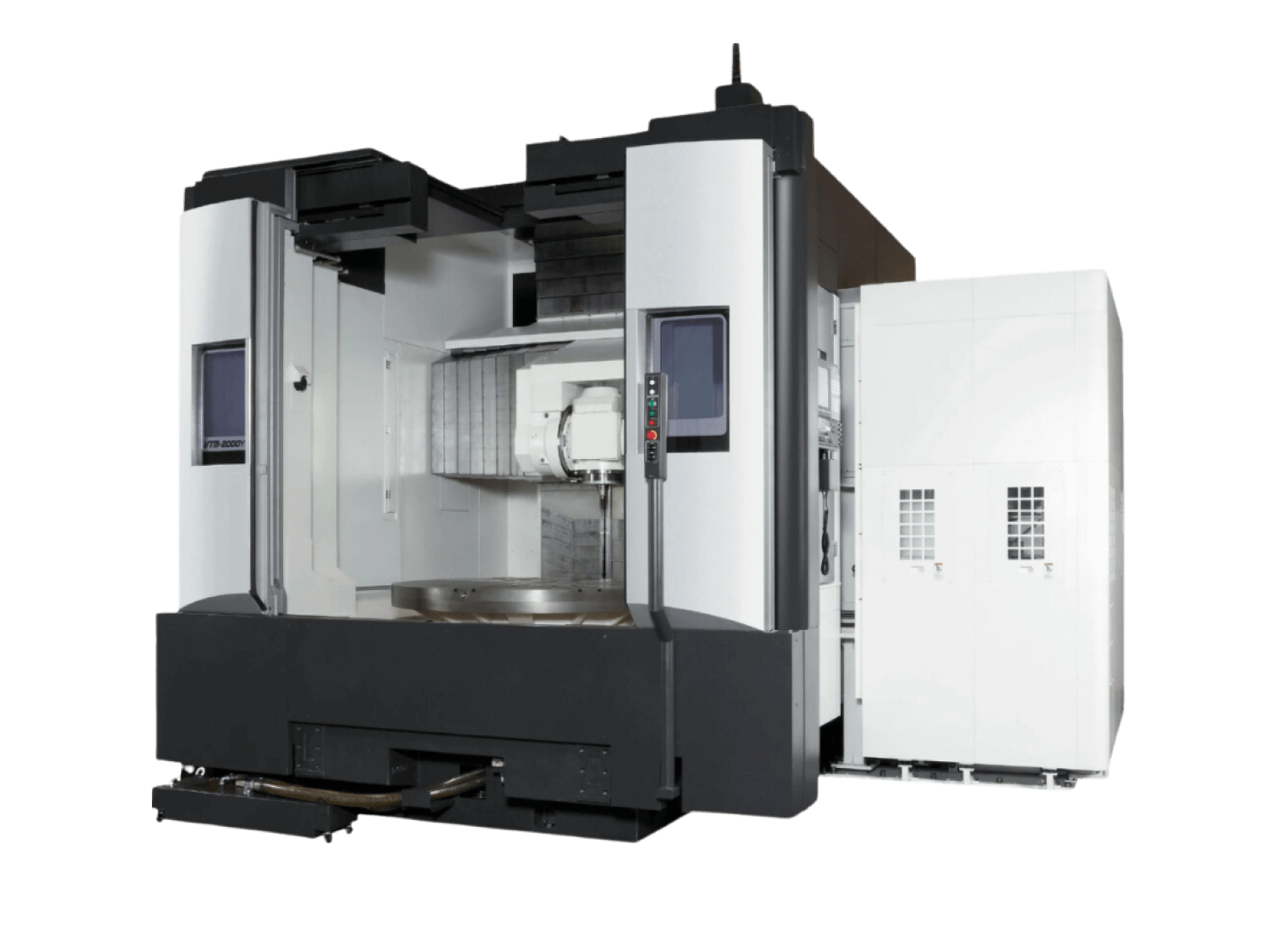

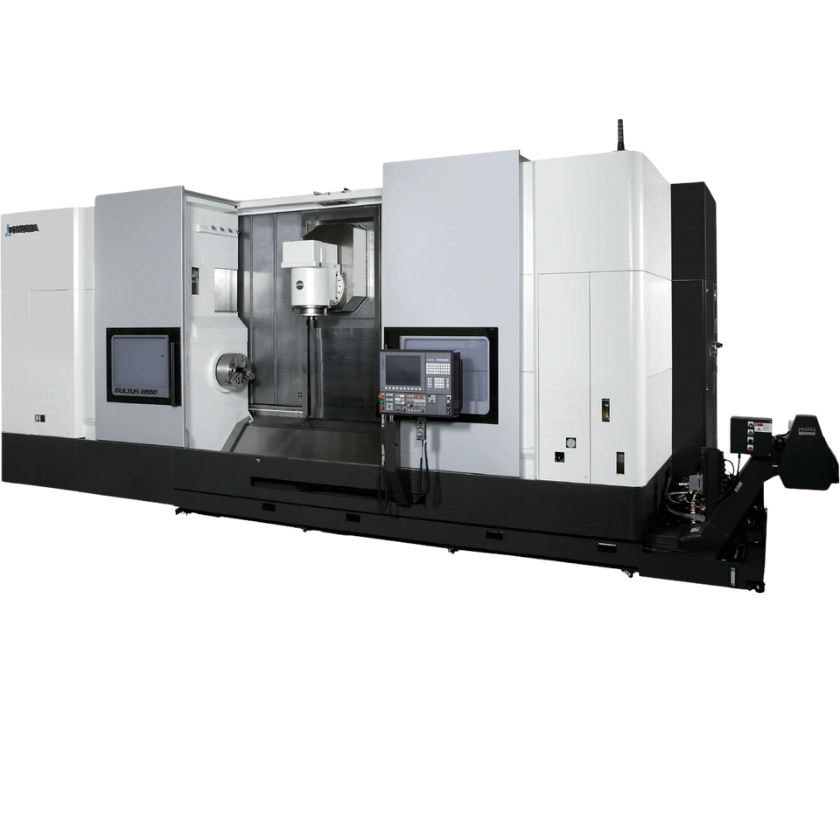

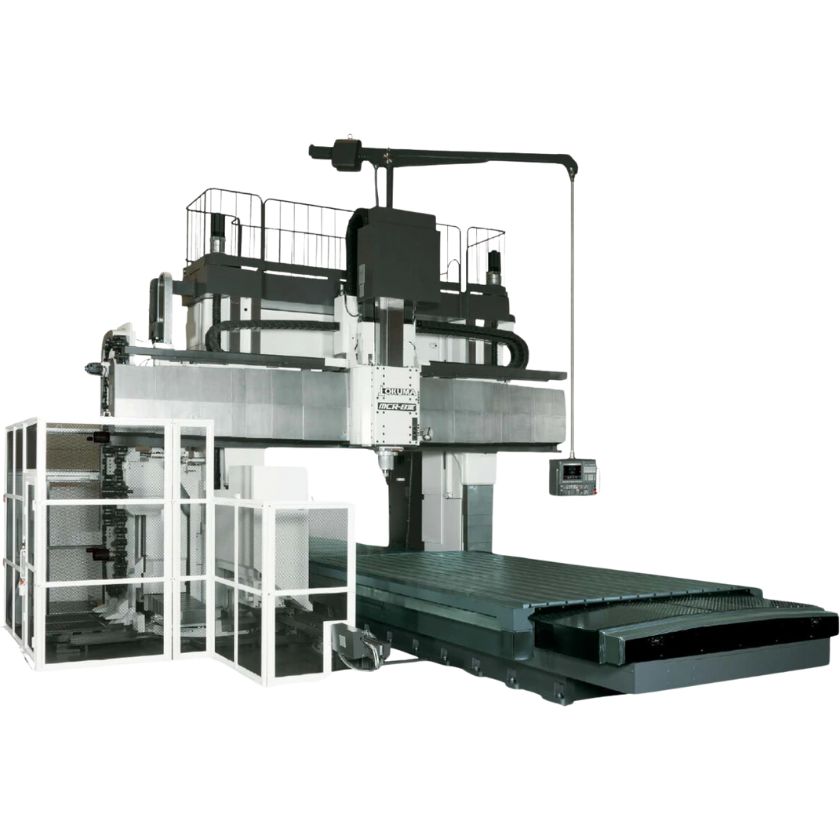

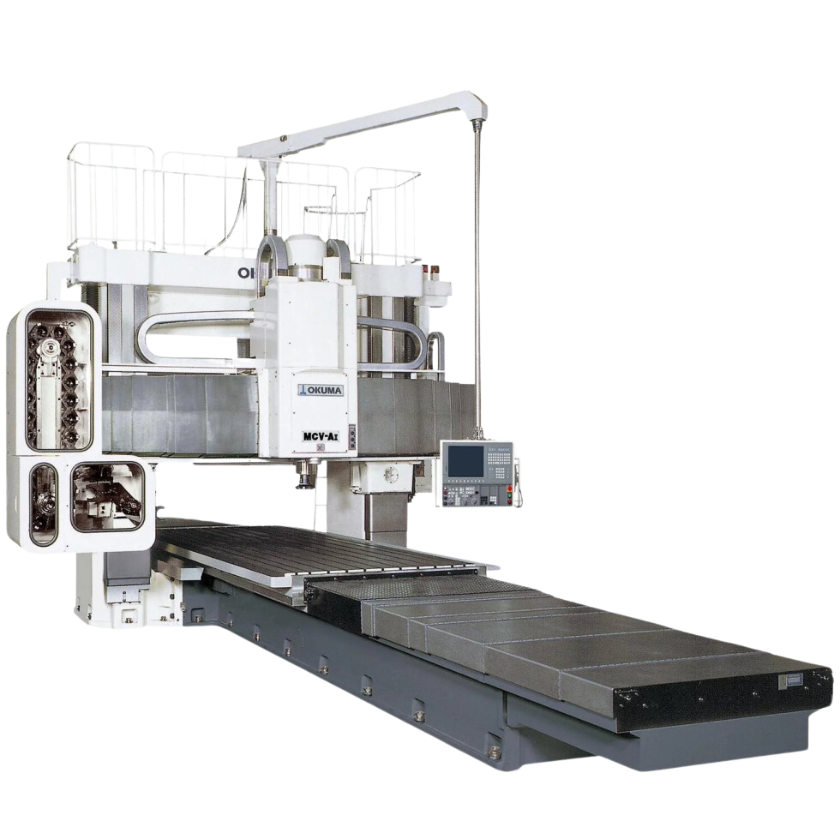

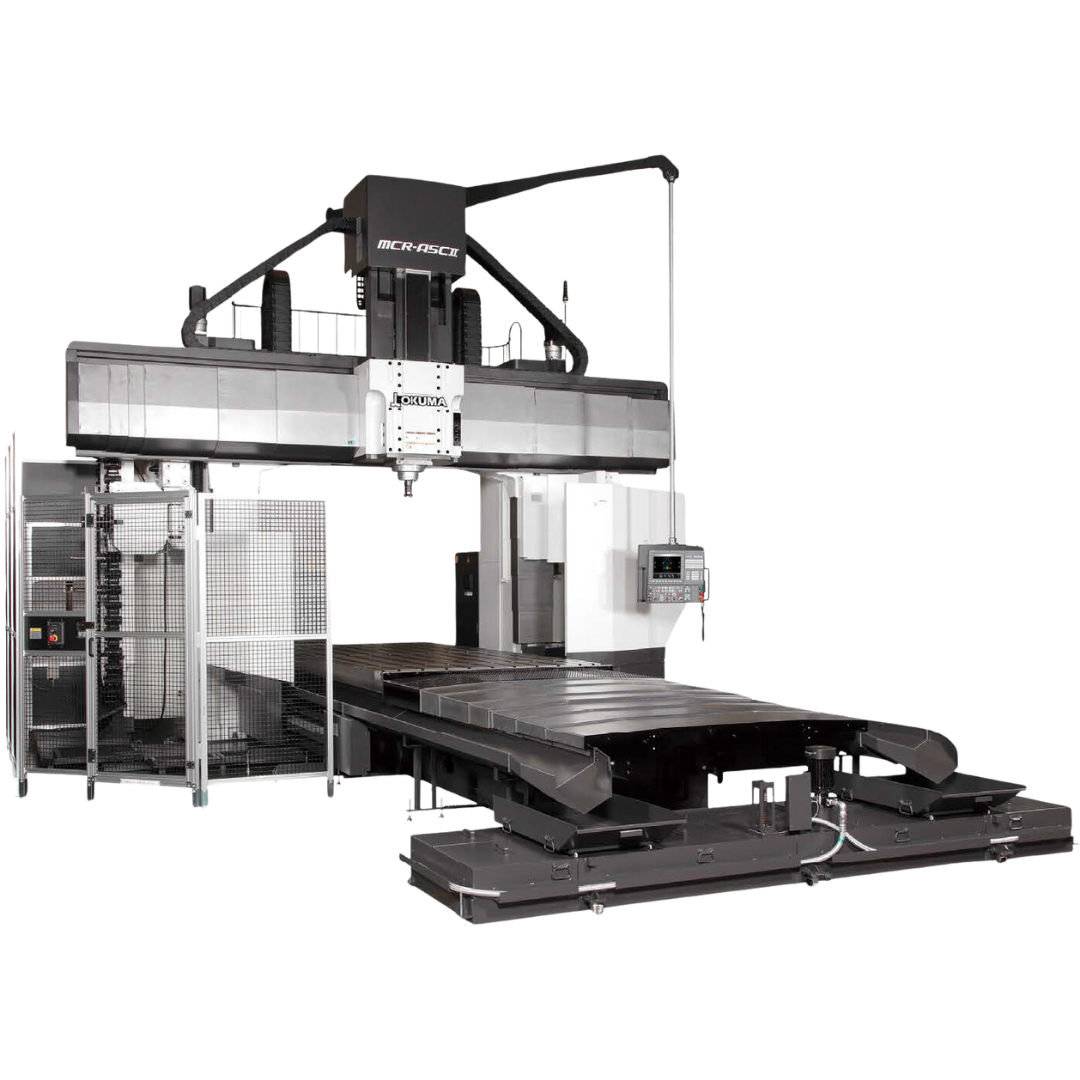

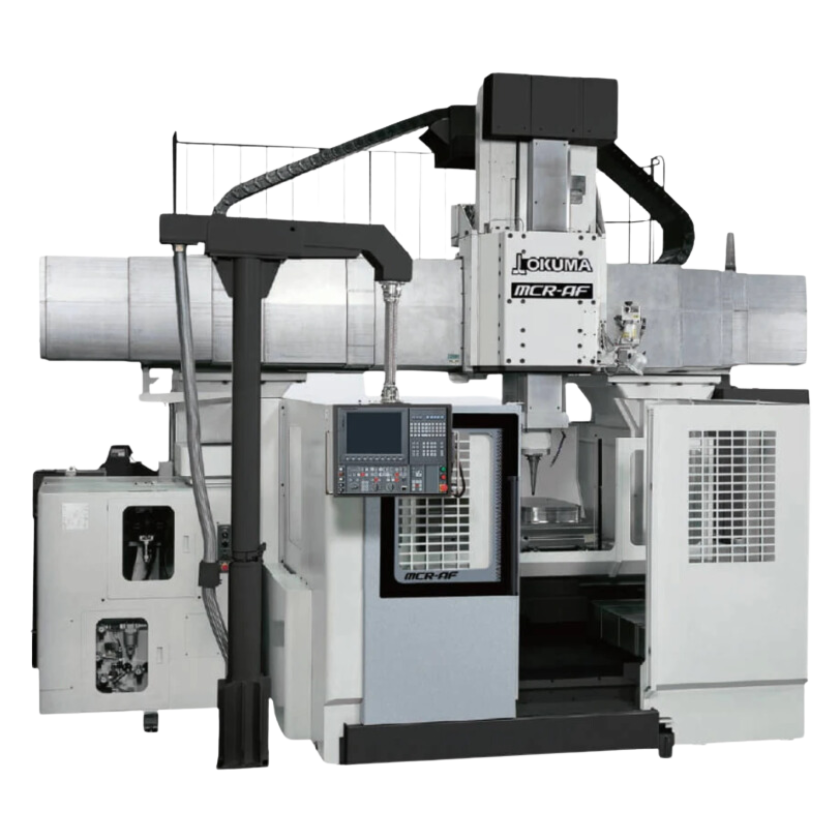

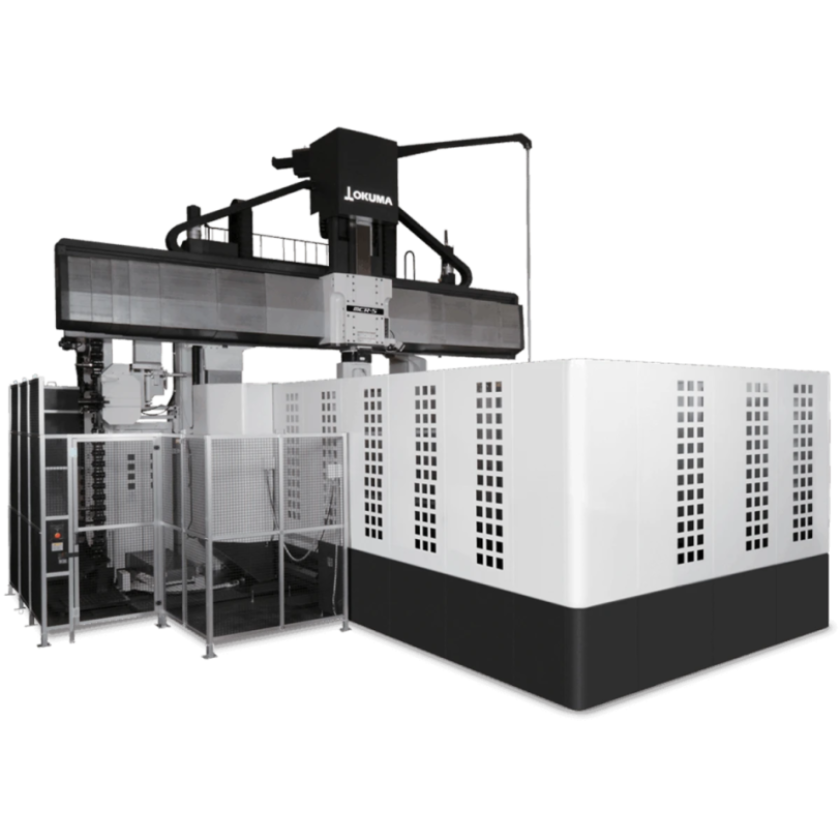

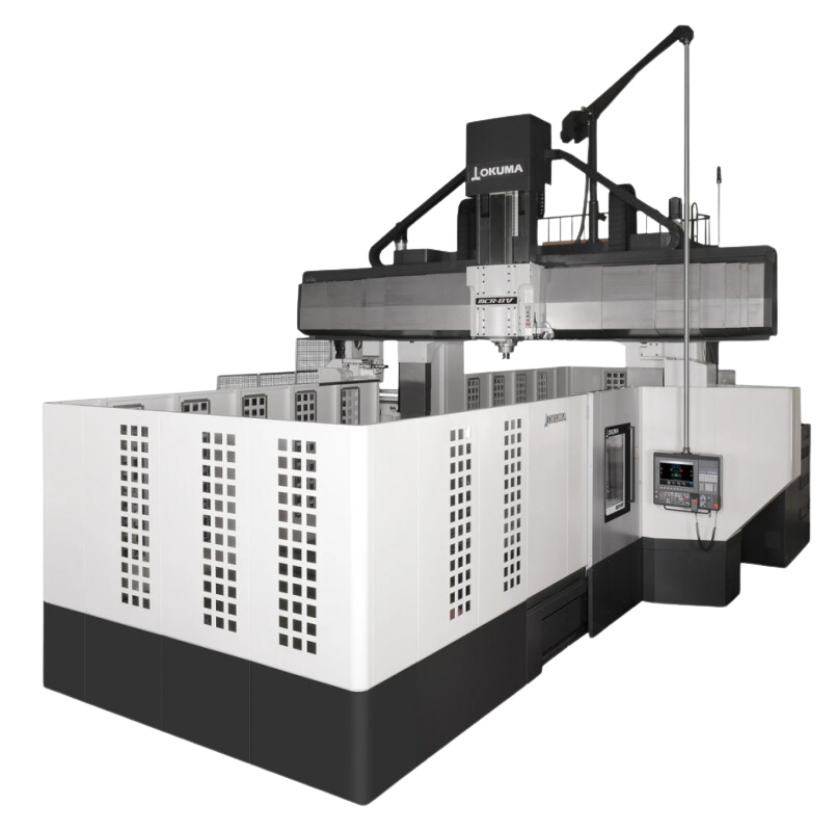

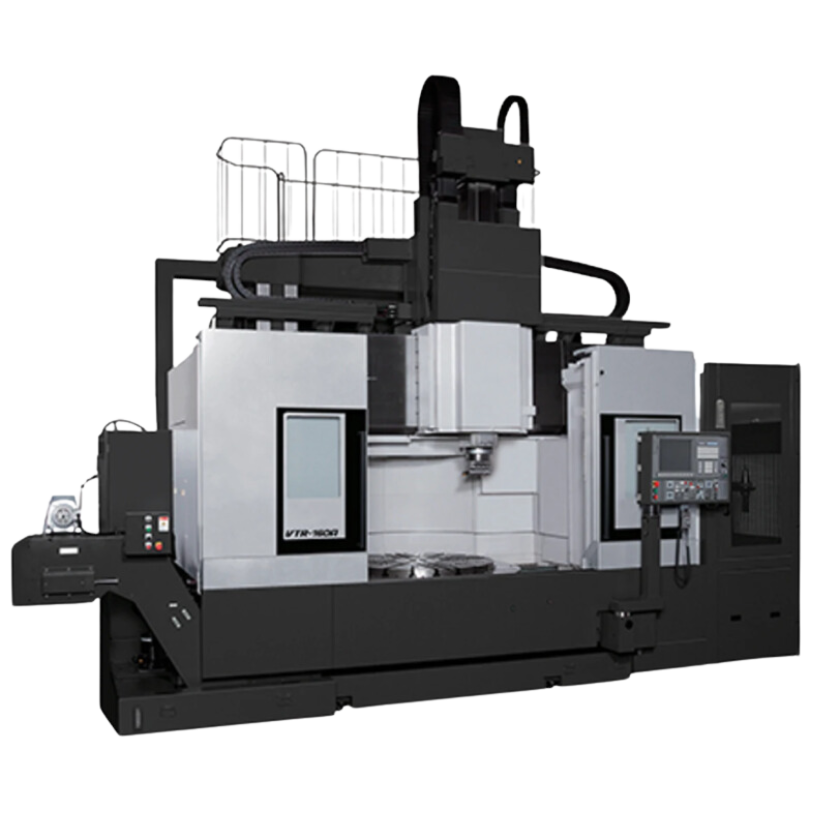

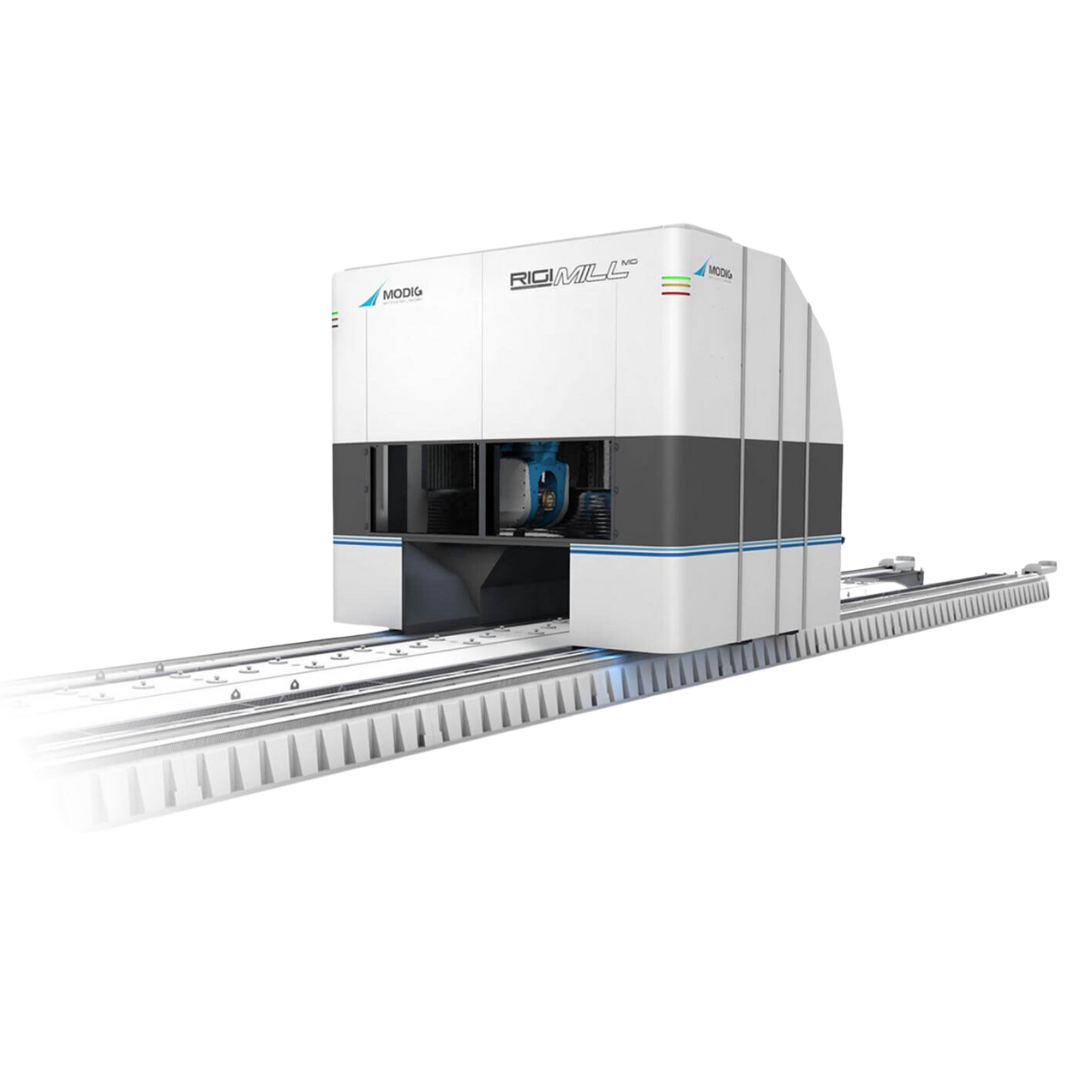

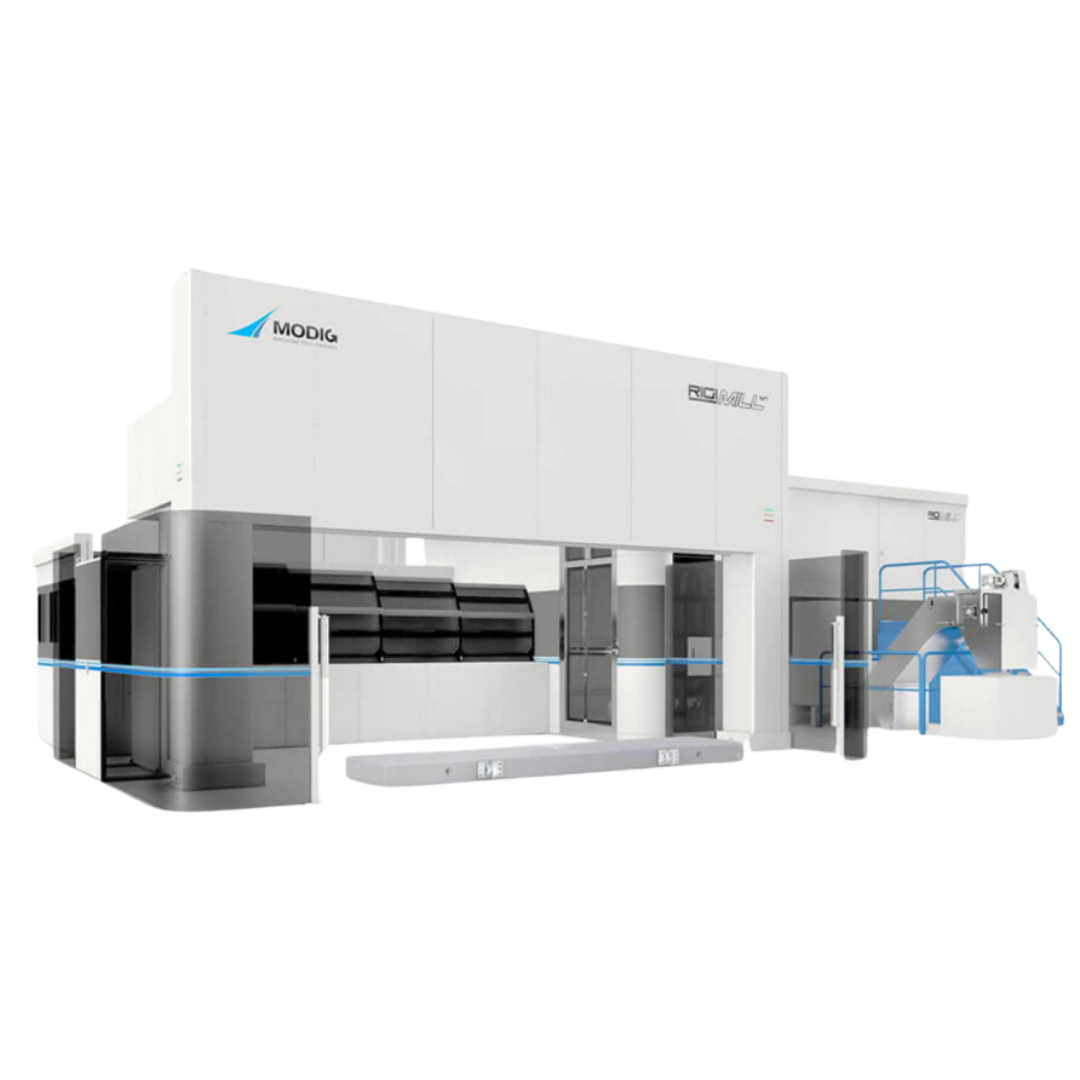

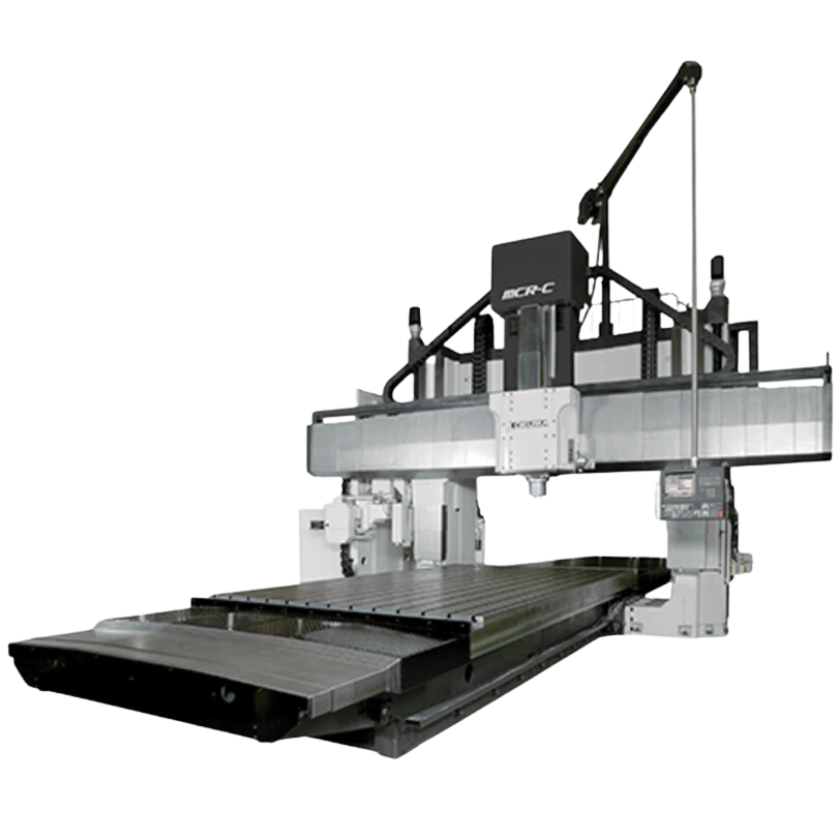

MCR-C

Product description

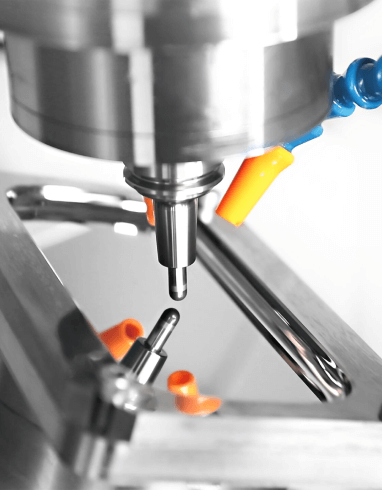

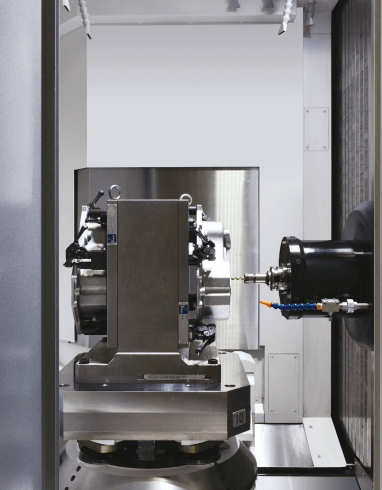

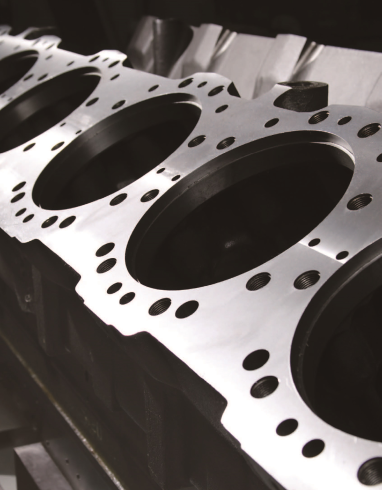

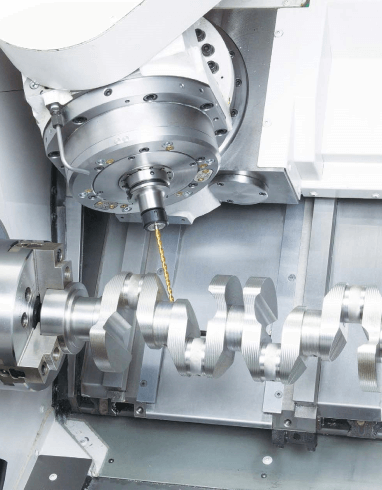

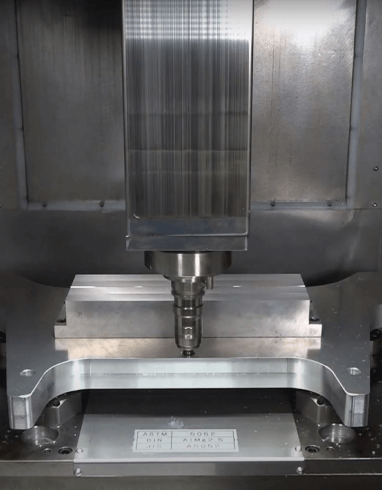

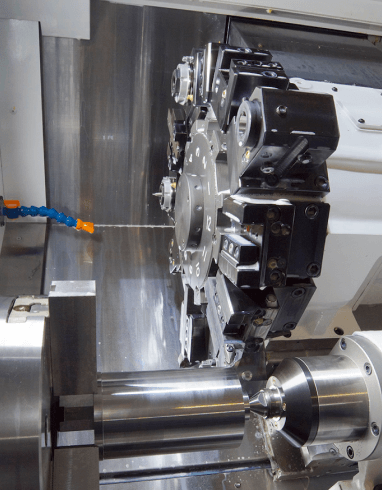

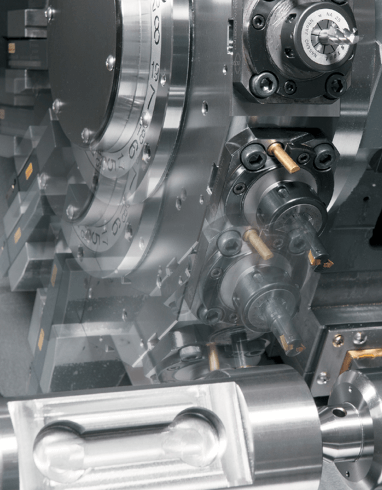

Okuma's MCR-C Double Column Machining Center was created to meet the demand of heavy industries for high power, high torque, and high productivity. The exceptionally rigid spindle delivers powerful, 5-axis cutting on a thermally stable machine that provides efficient and accurate machining of large components. The MCR-C double column machining center’s auto tool changer (ATC) and full array of available spindle heads (attachments) support the machining of all types and shapes of parts.

Industries

Aerospace

Automotive

Energy

Heavy Duty

Medical

Molds & Dies

Others

Product highlights

Spindle Range (min-1)

10~4,000 [10~6,000]

Spindle Power (hp)Spindle Power (kW)

60 / 50 [50 / 40]45 / 37 [37 / 30]

Rapid Traverse Rate X-Y / Z (ipm)Rapid Traverse Rate X-Y / Z (m/min)

944.88 / 590.5524 / 15

Magazine Capacity

50 [80, 100, 120, 180]

Width Between Columns (in)Width Between Columns (mm)

104.33 [124.02, 143.70] 2,650 [3,150; 3,650]

Table Travel (X-Axis) (in)Table Travel (X-Axis) (mm)

165.35 [204.72 - 480.31] 4,200 [5,200 - 10,200]

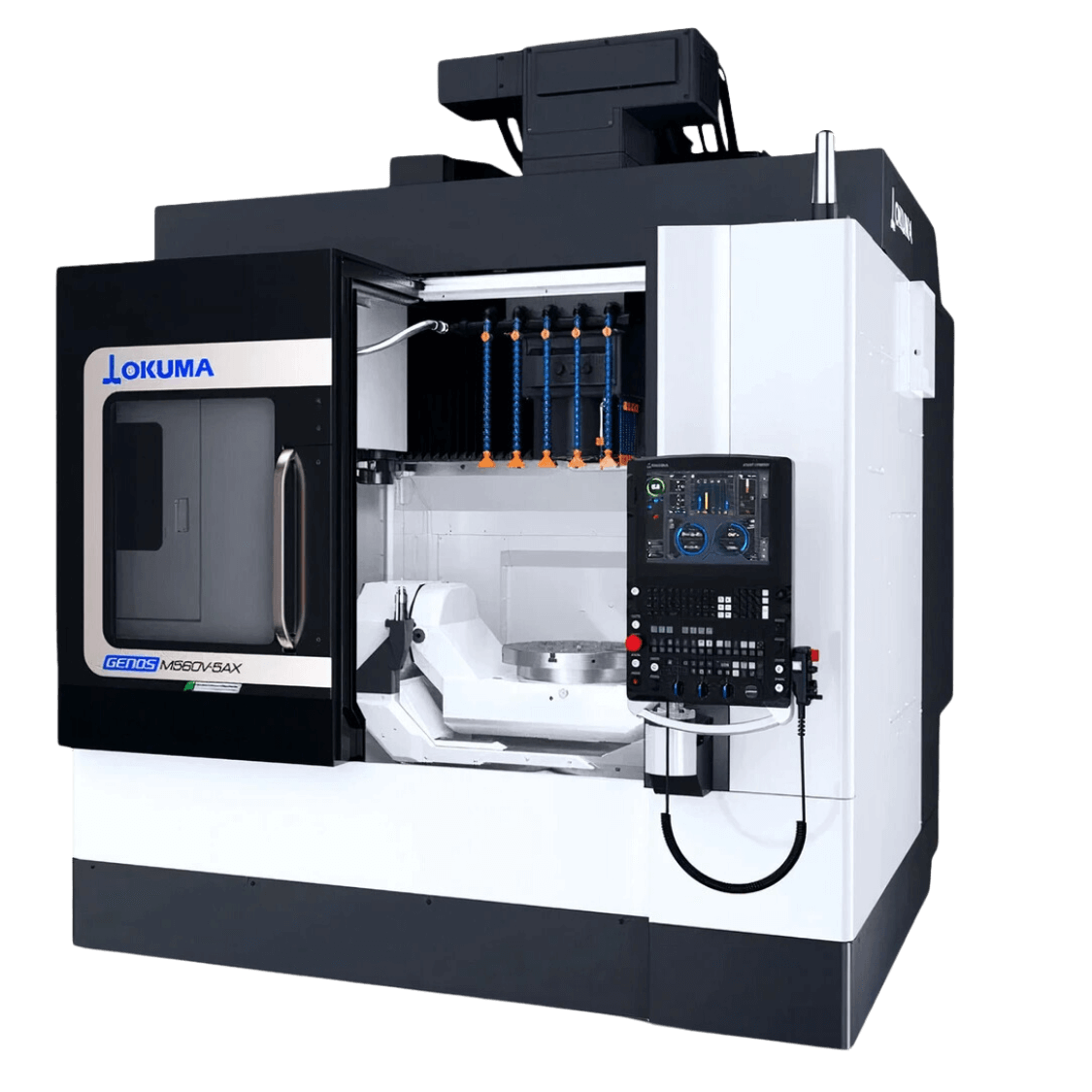

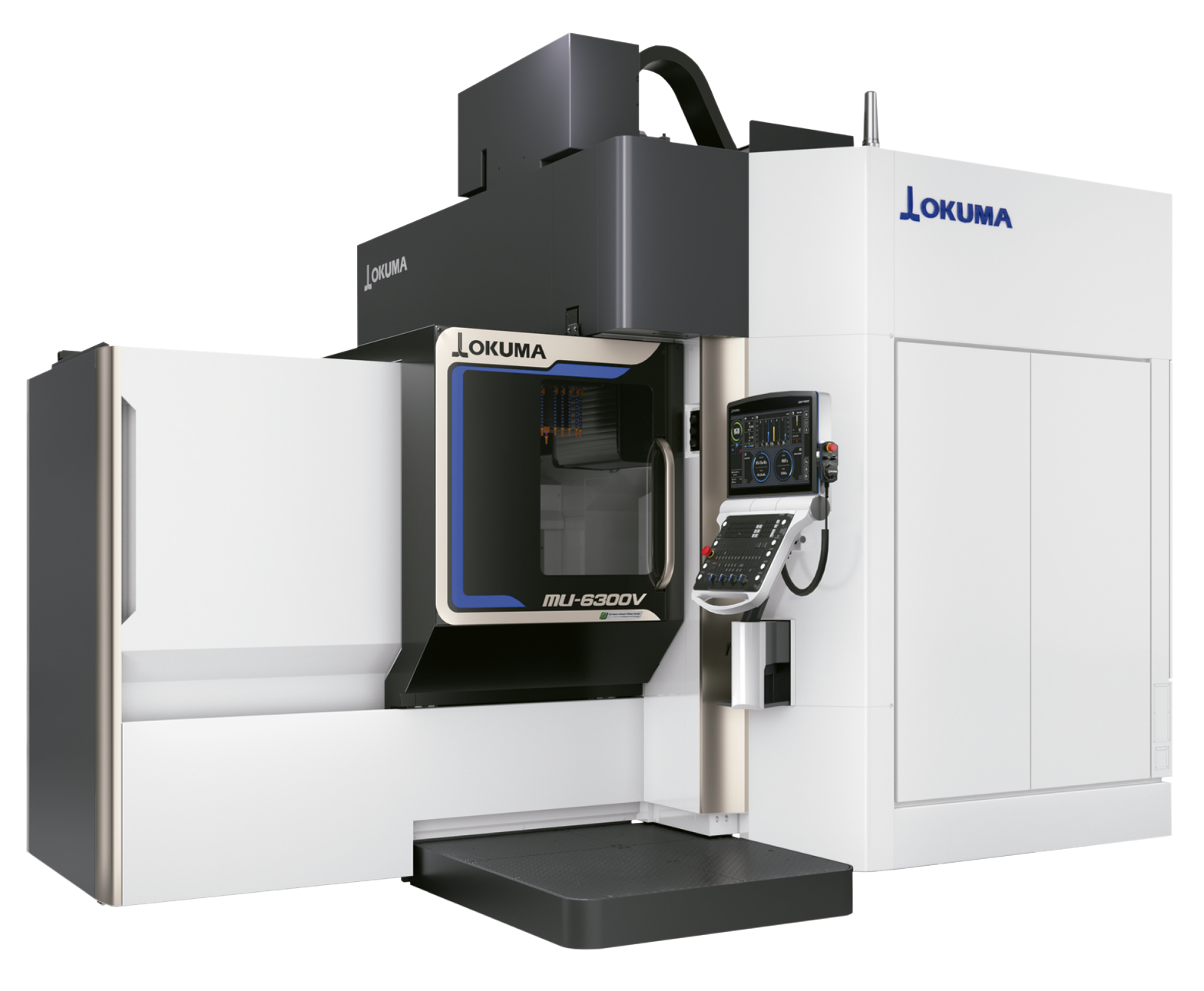

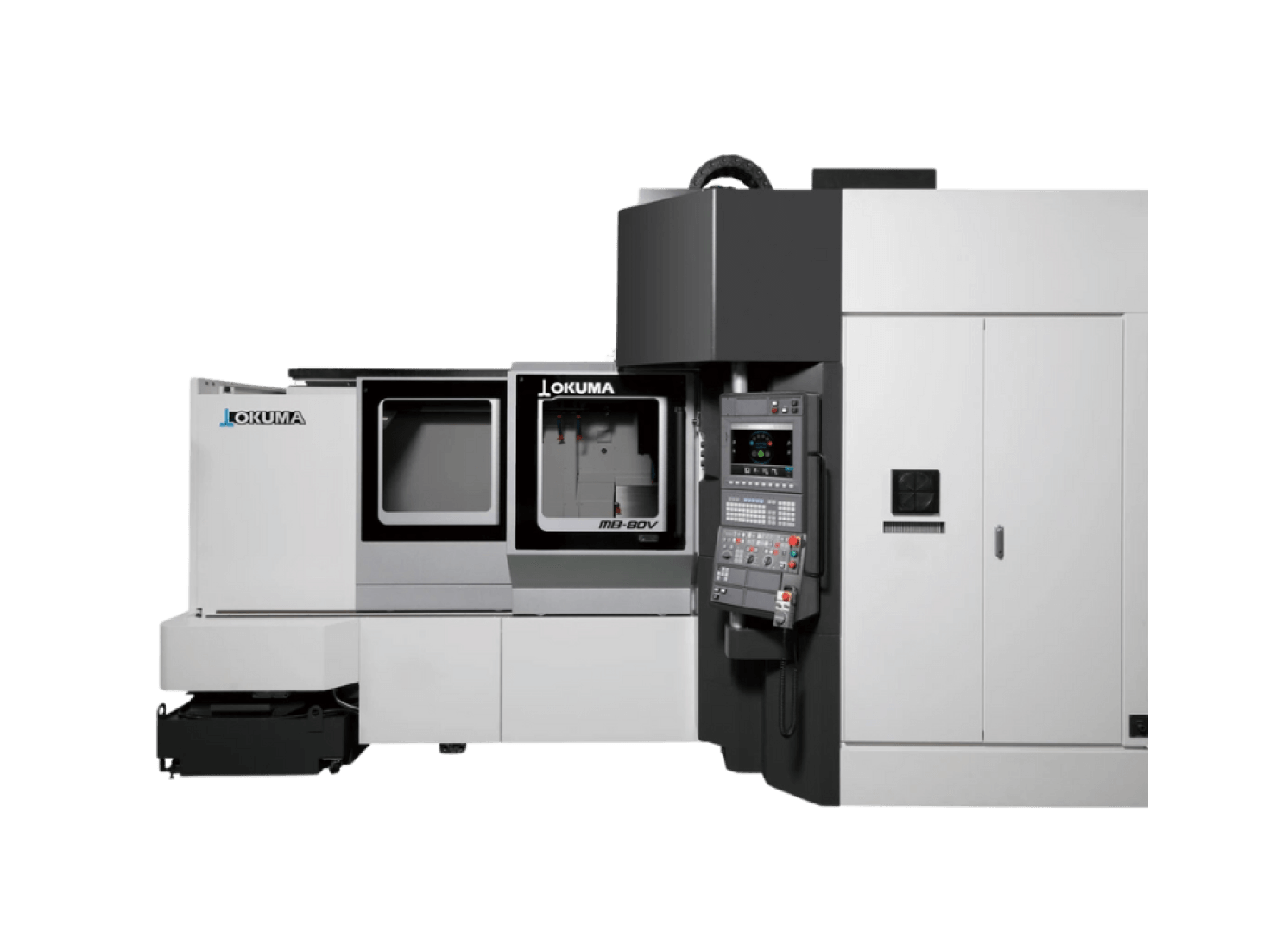

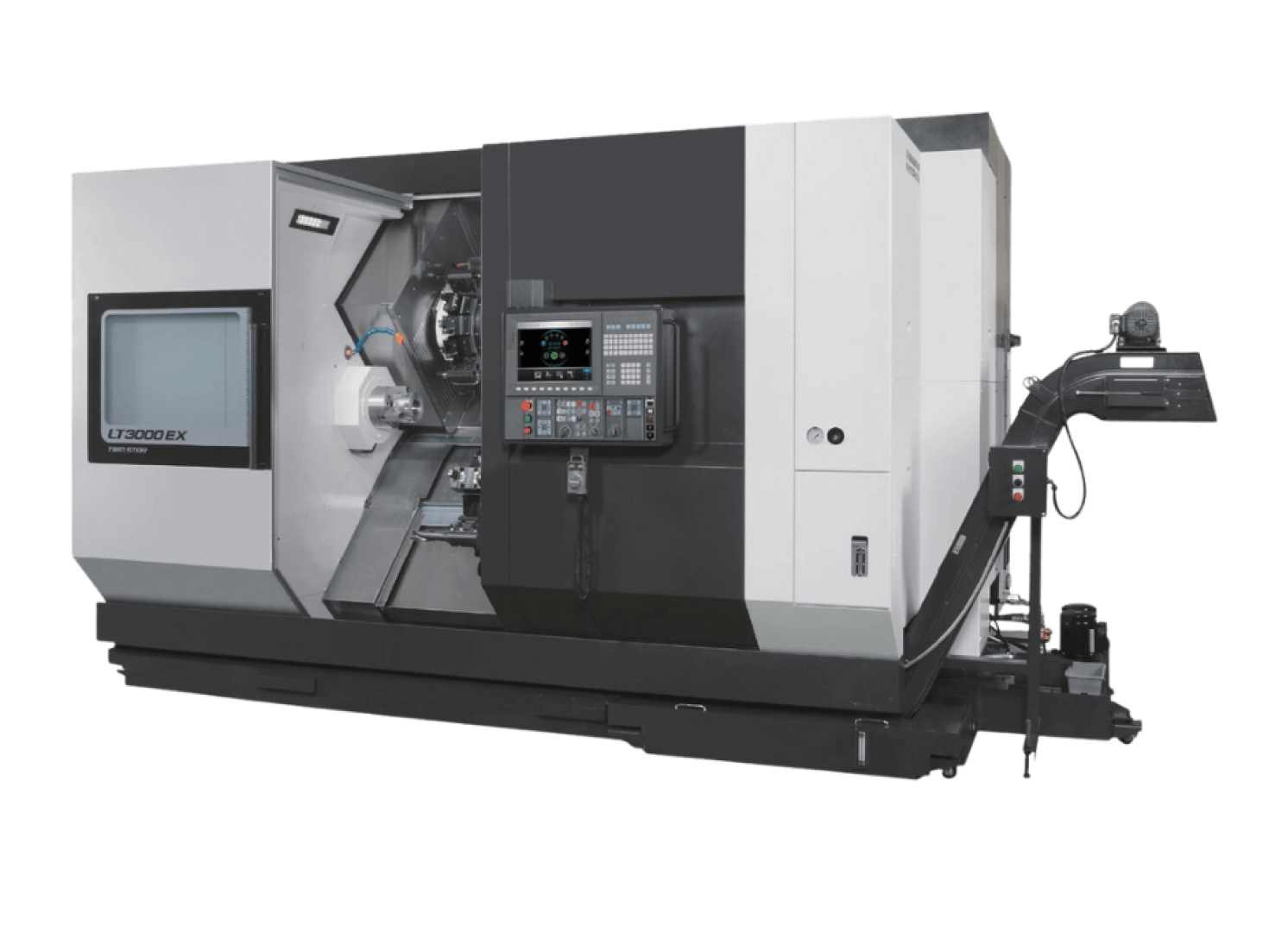

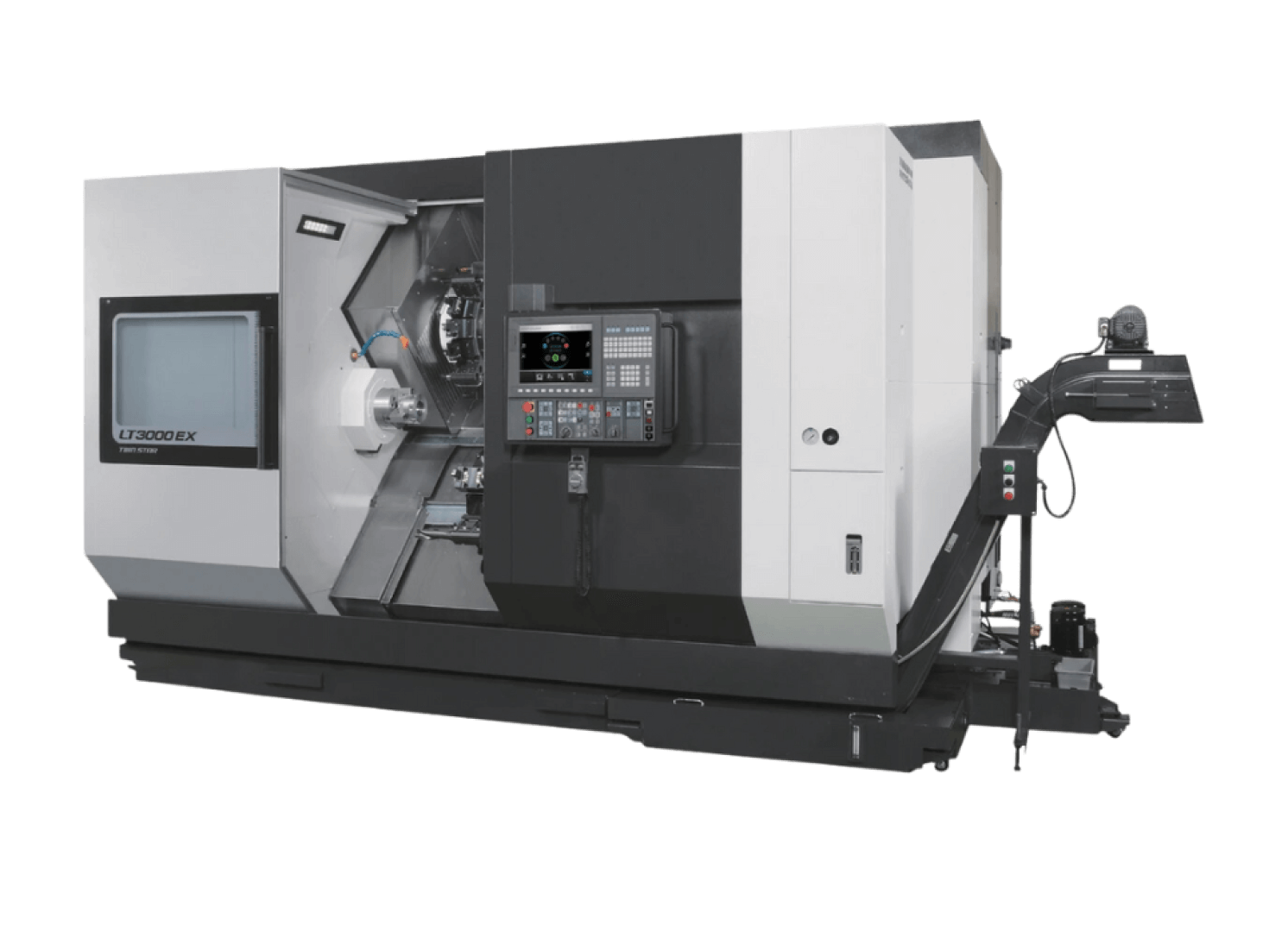

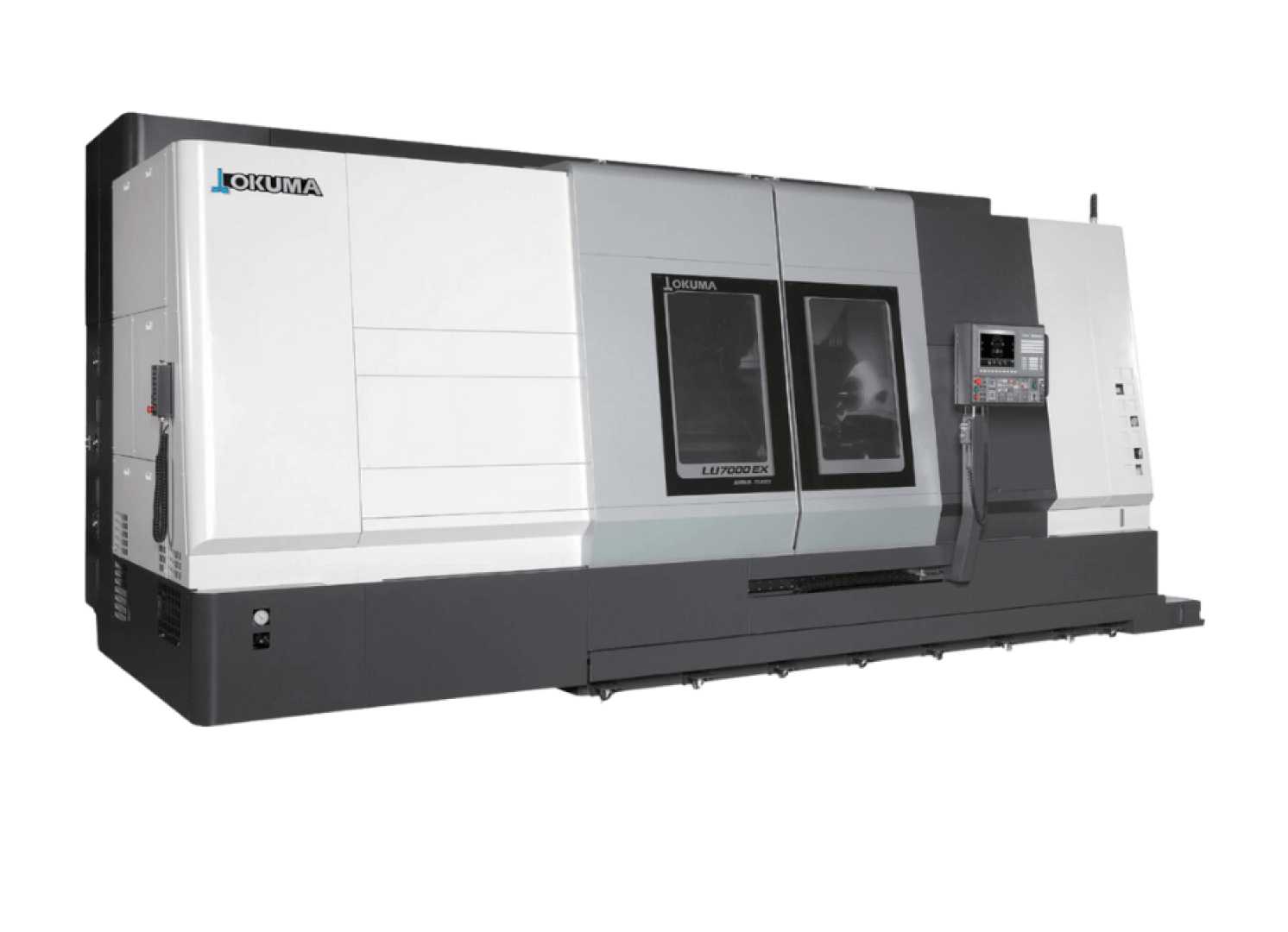

Frequent combinations to improve your processes in CNC Lathes, CNC Machining Centers, and other Machining Equipment.

Equip and maximize the productivity of your CNC machines with comprehensive solutions.

Accessories and peripherals

Mist collector

Cooling system

Coolant filtration equipment and magnetic separator

Learn more about PERIFERIQ

Design and development of industrial automation tailored to your needs

Automatic doors

Automated loading and unloading systems

Safety and cleaning systems

Interfaces for external workholding systems

Learn more about OTOMATIQA