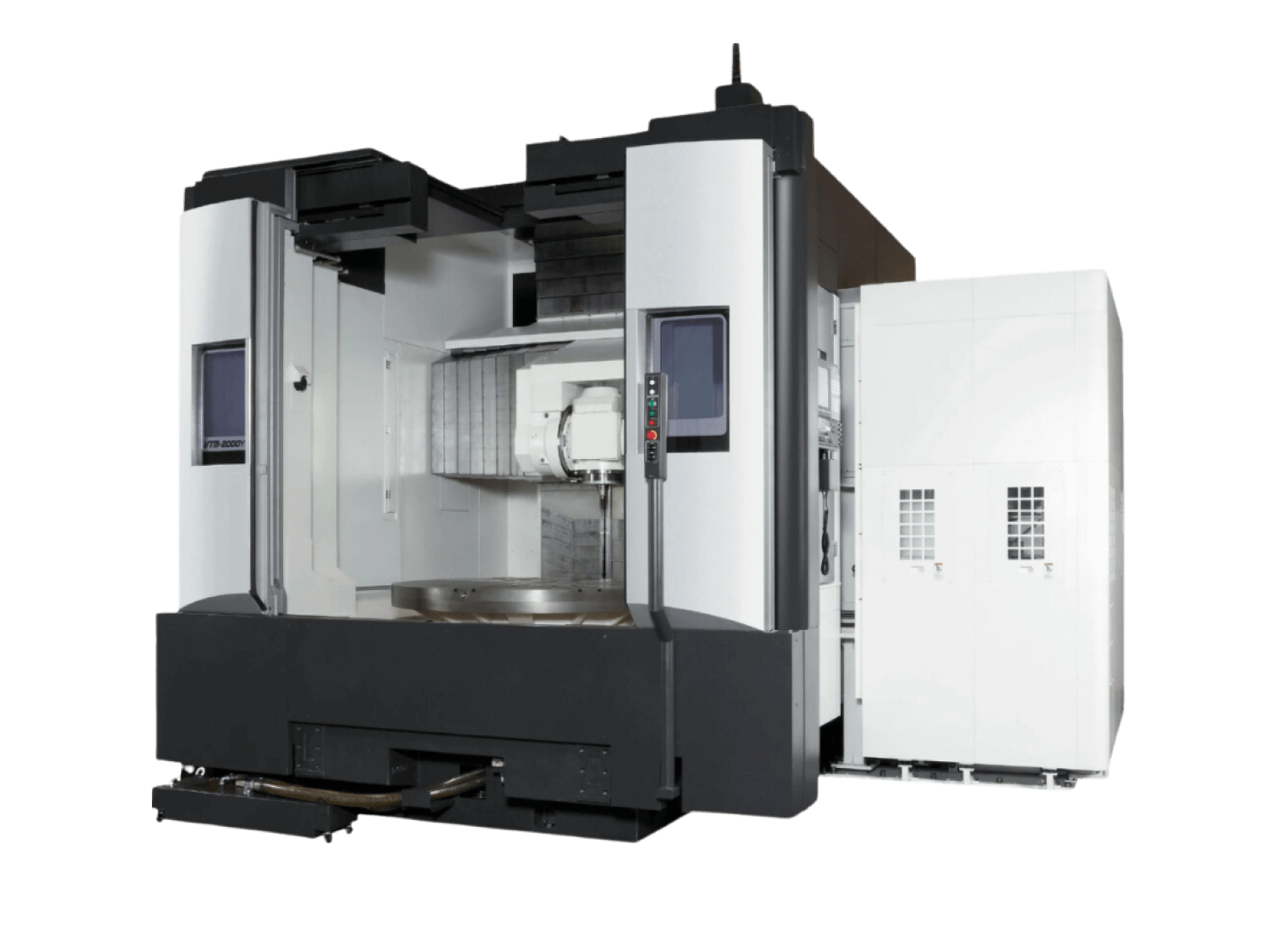

OKUMA

OKUMA

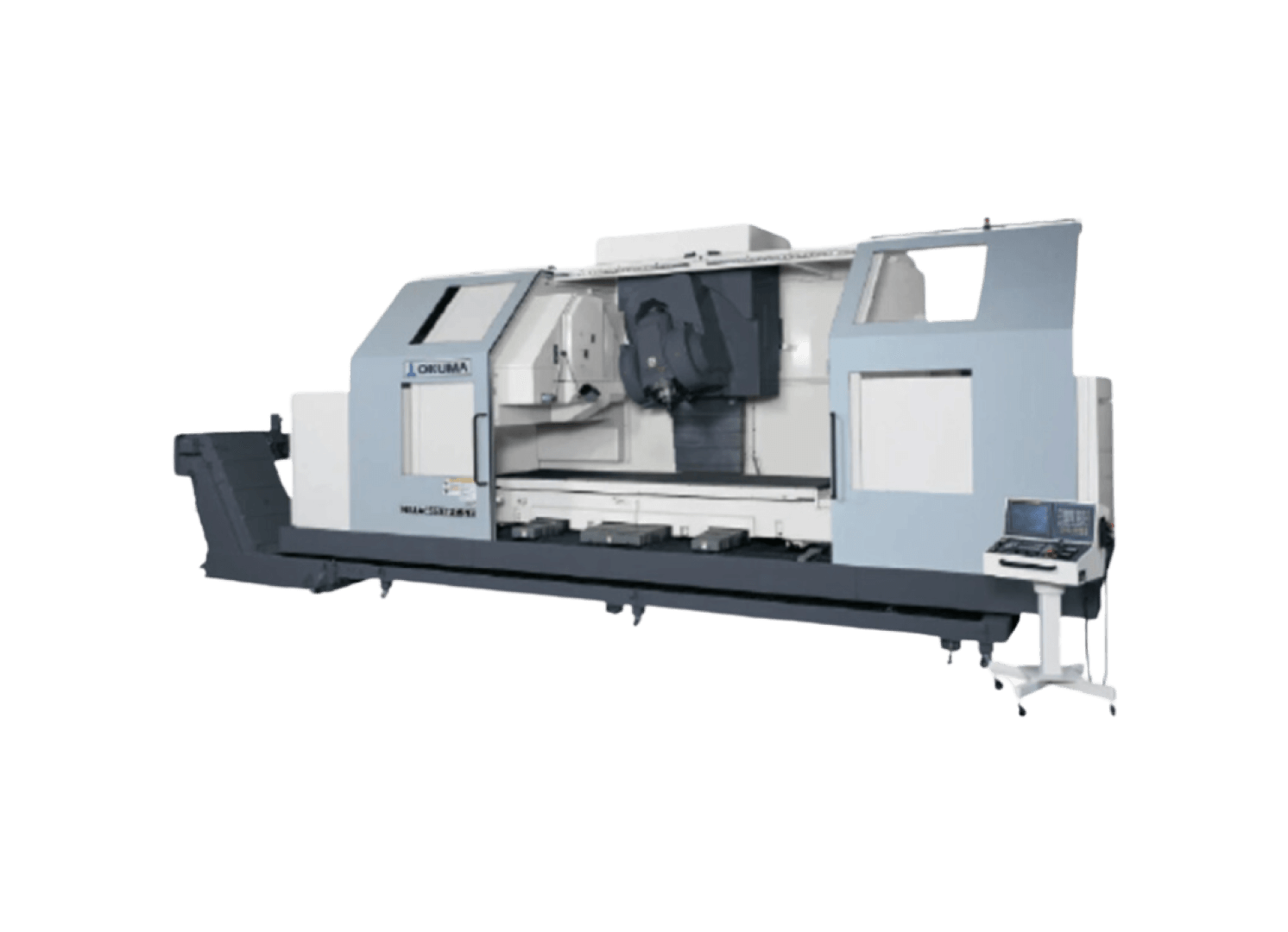

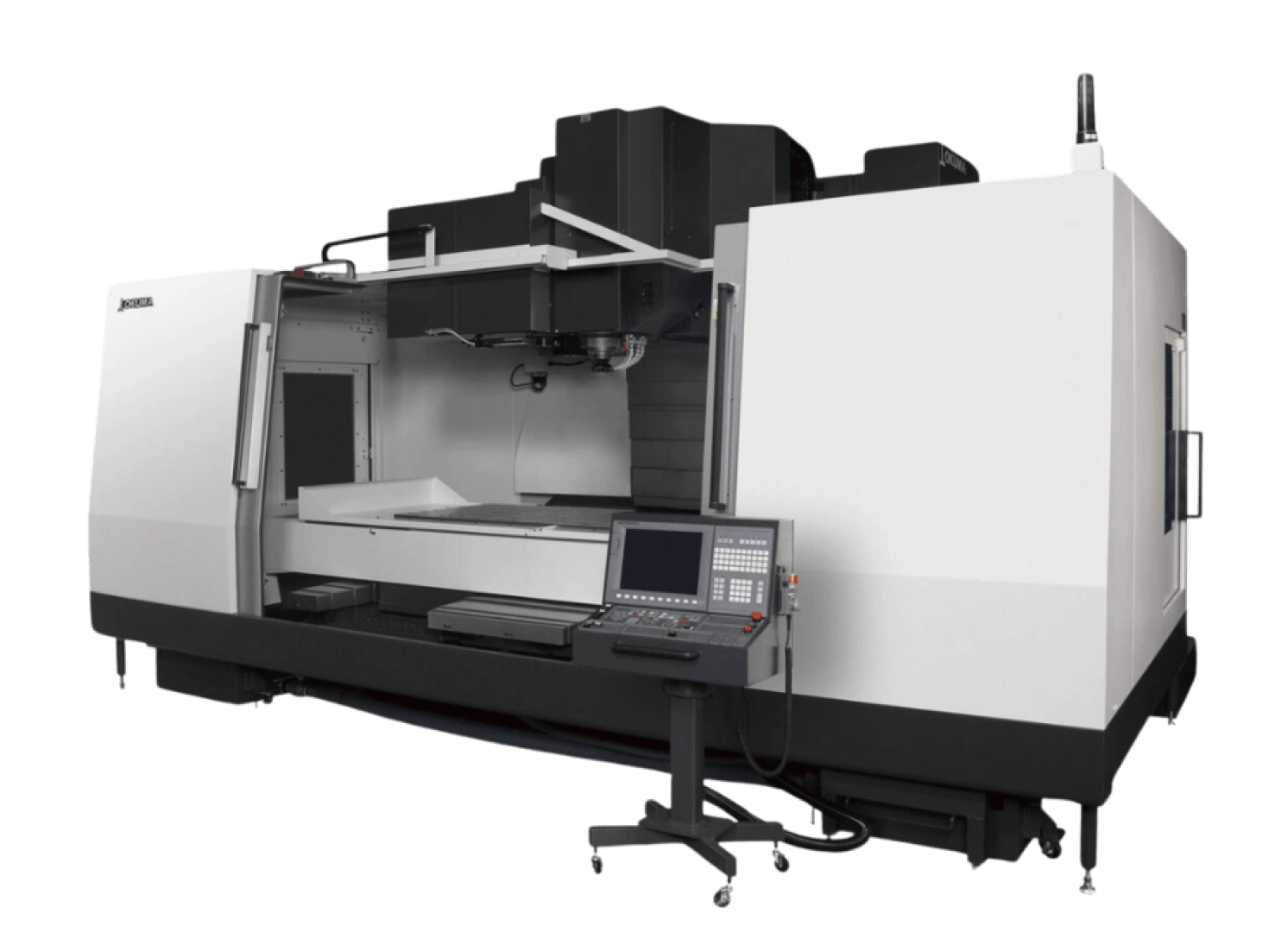

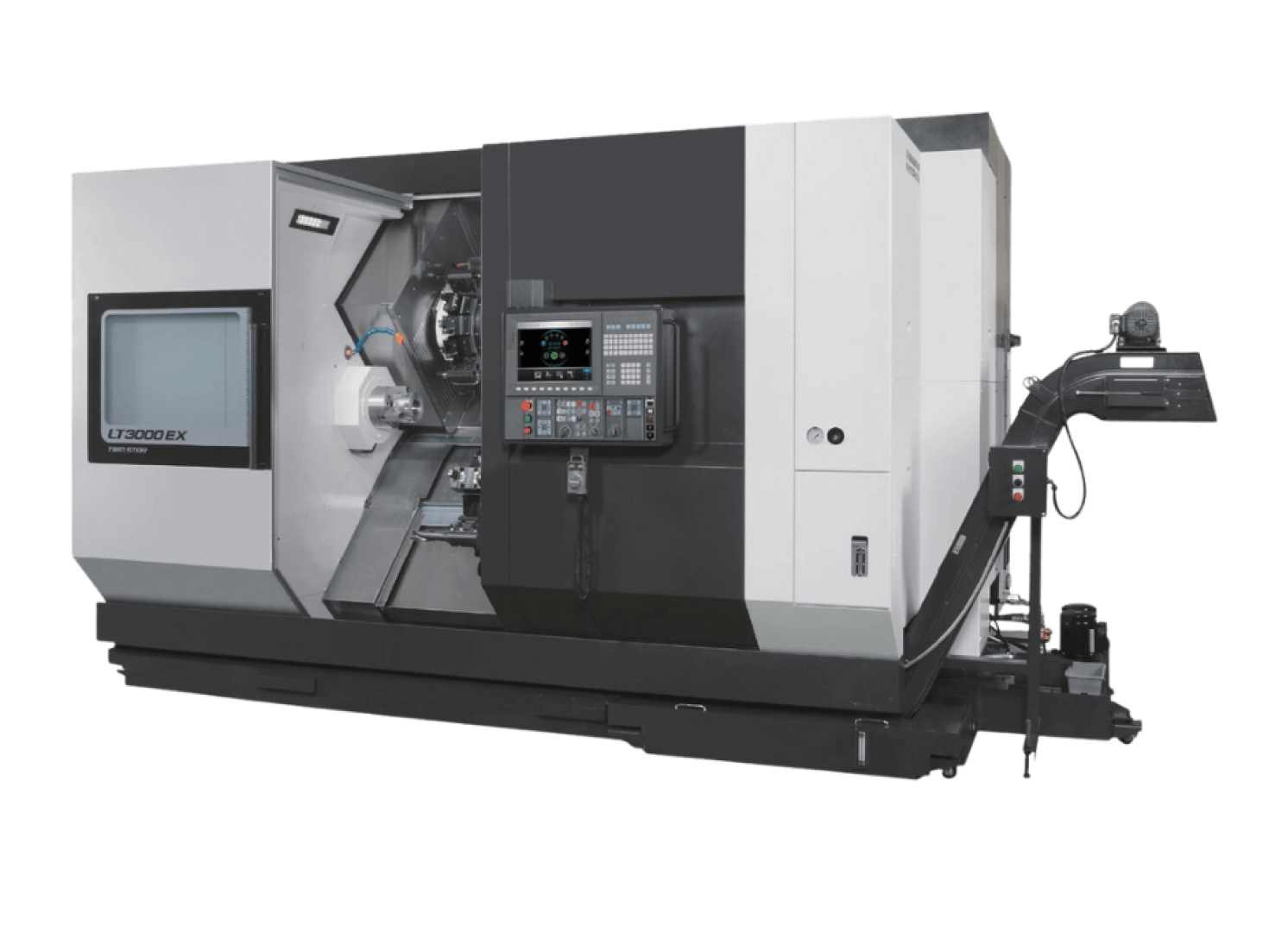

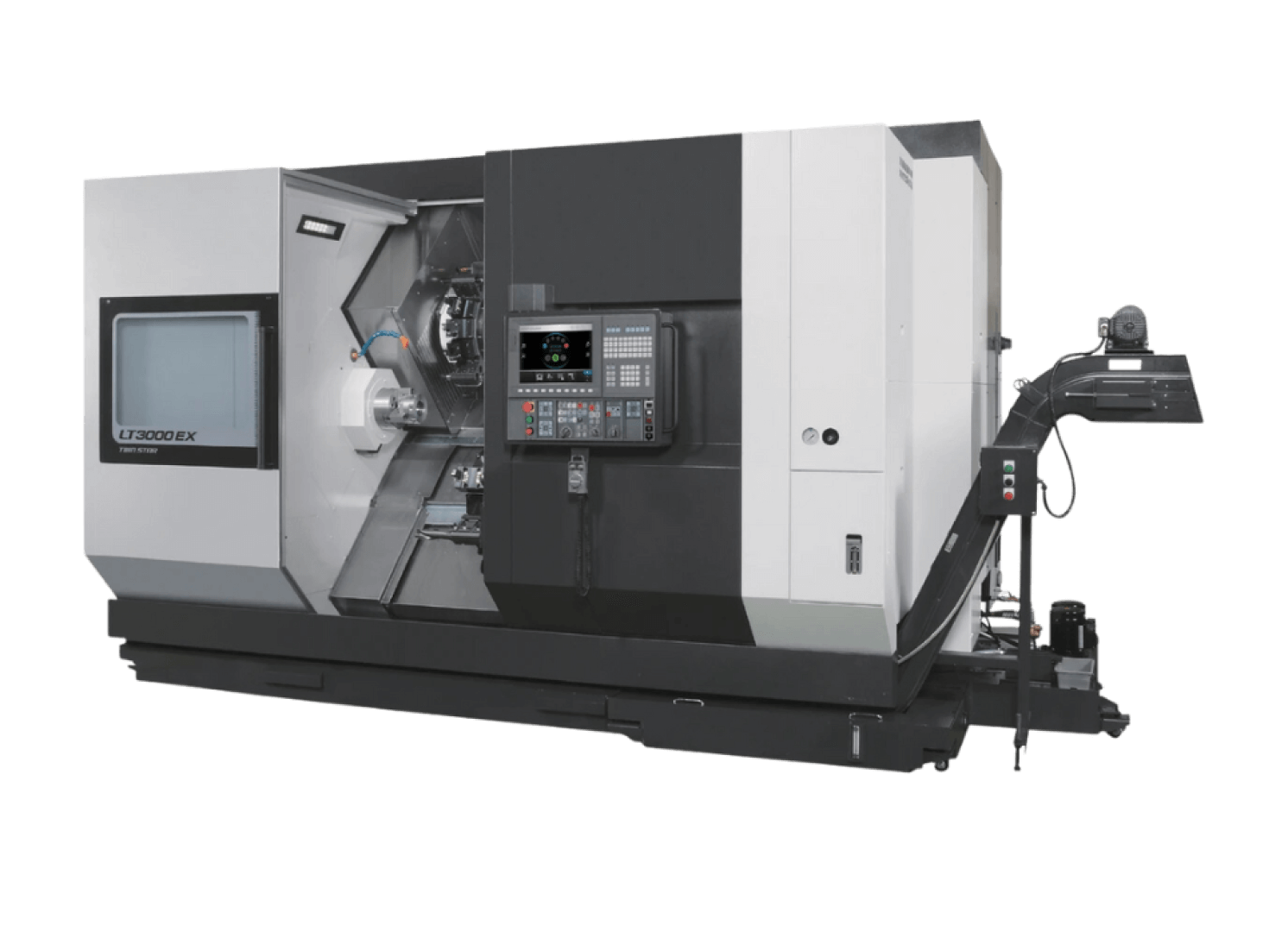

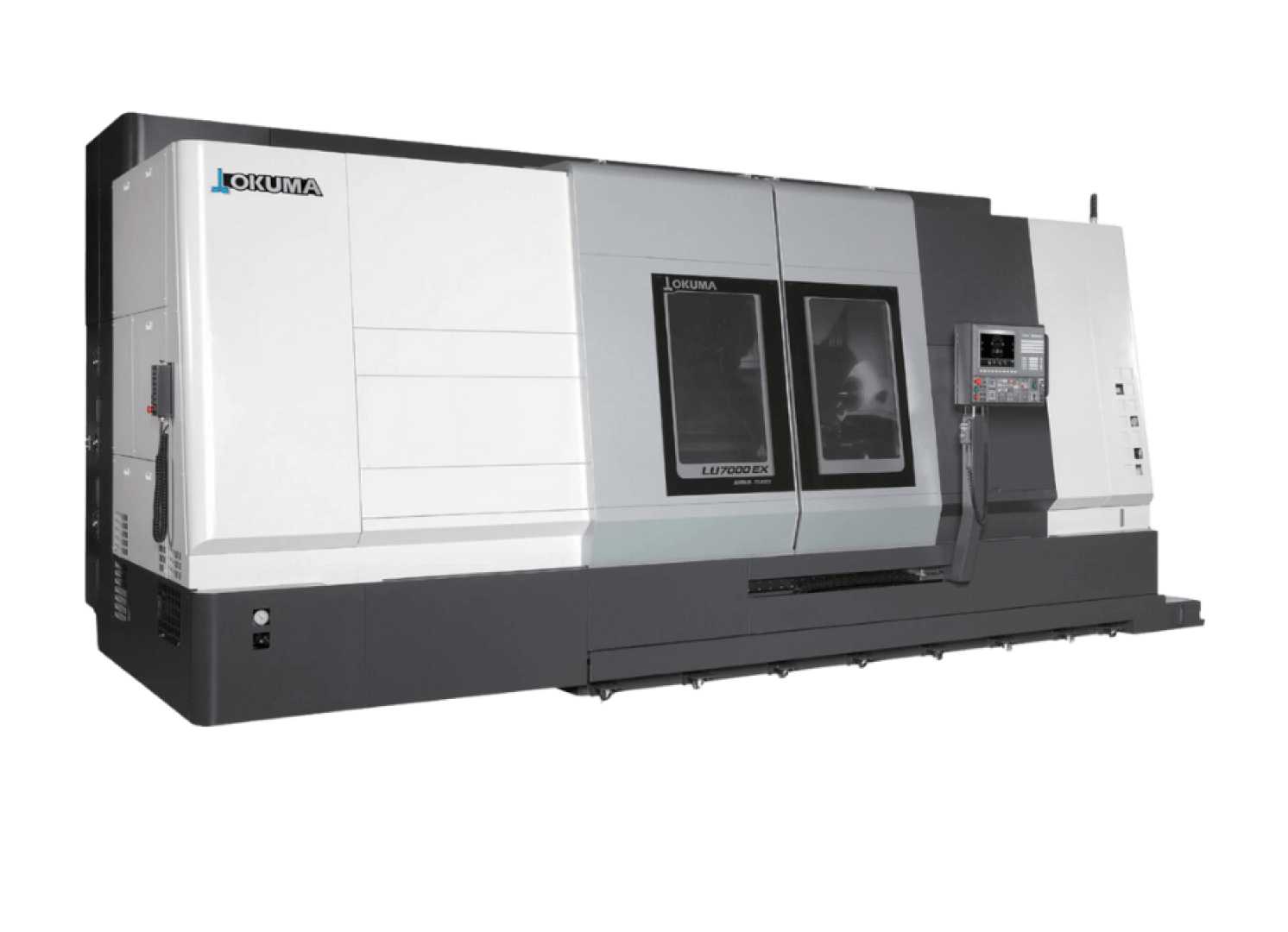

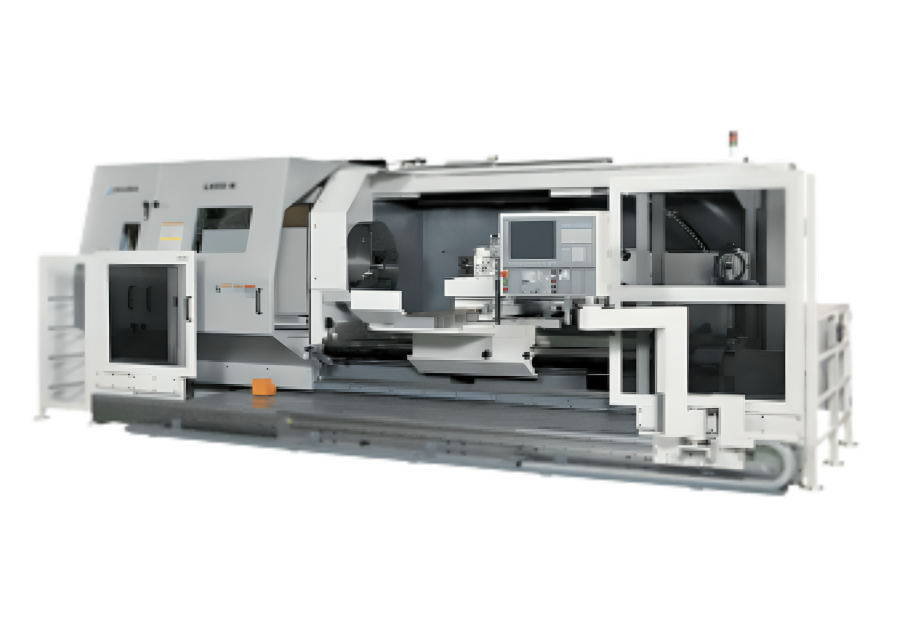

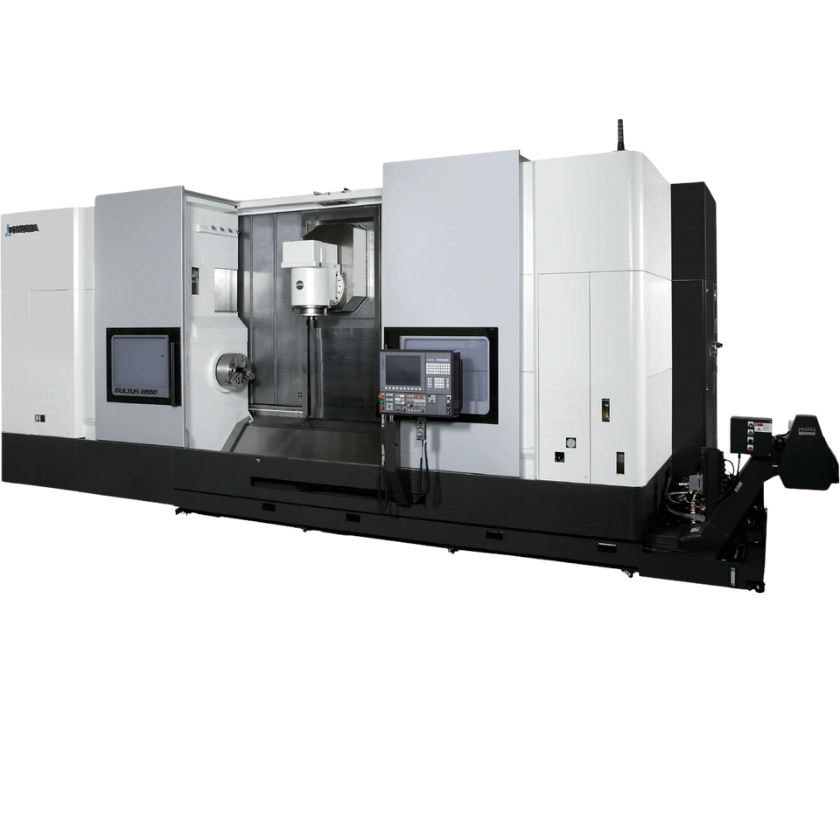

LOC500

Product description

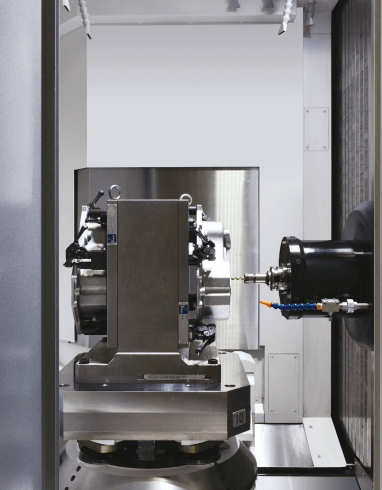

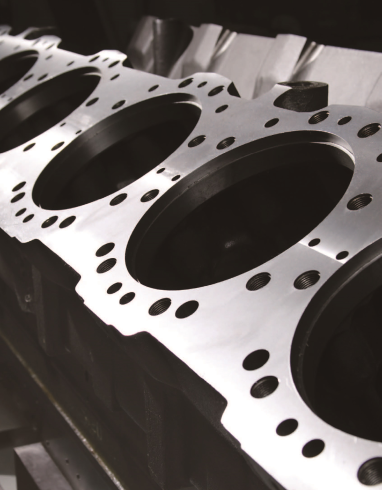

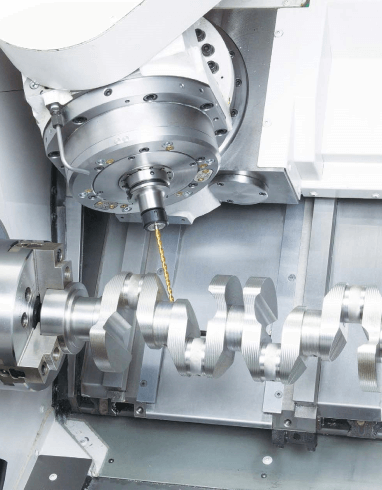

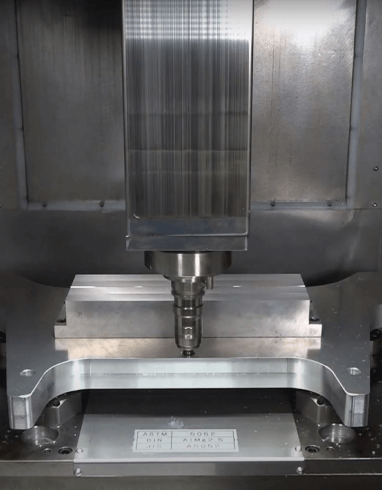

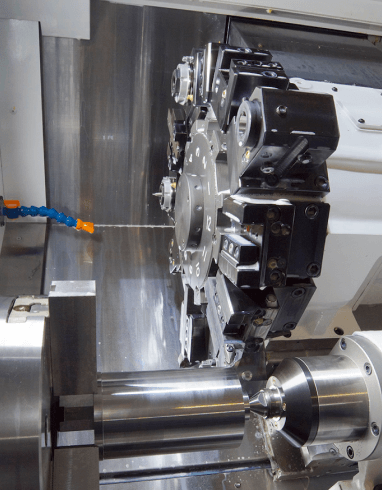

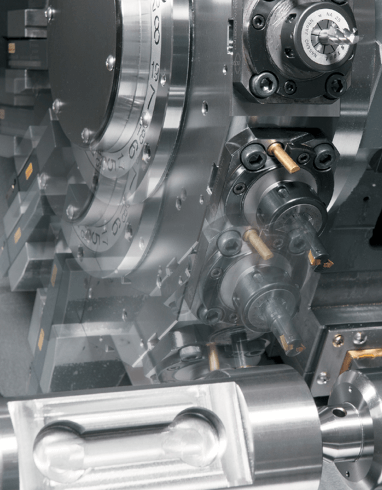

The Okuma LOC500 Lathe is specially designed for the needs of the oil industry. It is capable of performing tighter threading functions on large pipes with precision and speed. It has three spindle drilling variants specifically designed for this machine, which can accommodate large diameter pipes. It has a power of 37/30 kW and a spindle speed of 5~500 min⁻¹, as well as a maximum turning diameter of ø660 mm and a maximum turning length of 1,750 mm. It has a 12-position turret with optional live tools, plus Okuma's Threading Suite system, which combines variable speed threading and harmonic spindle control.

Industries

Energy

Heavy Duty

Others

Key product information

Max Turning Diameter (in)Max Turning Diameter (mm)

25,98 660

Speed Range (min⁻¹)

5.59”: 11~2,000; 7.28”: 10~1,500; 10.83”: 10~1,000

Standard Power (hp)Standard Power (kW)

5.59”: 50/40, 7.28”: 60/50, 10.83”: 74/60 142: 37/30, 185: 45/37, 275: 55/45

Rapid Traverse X/Z (ipm)Rapid Traverse X/Z (m/min)

5.59”: 50/40, 7.28”: 60/50, 10.83”: 74/60 142: 37/30, 185: 45/37, 275: 55/45

Spindle Nose Type

5.59”: JIS A2-11, 7.28”: JIS A2-15, 10.83”: JIS A2-20

Frequent combinations to improve your processes in CNC Lathes, CNC Machining Centers, and other Machining Equipment.

Equip and maximize the productivity of your CNC machines with comprehensive solutions.

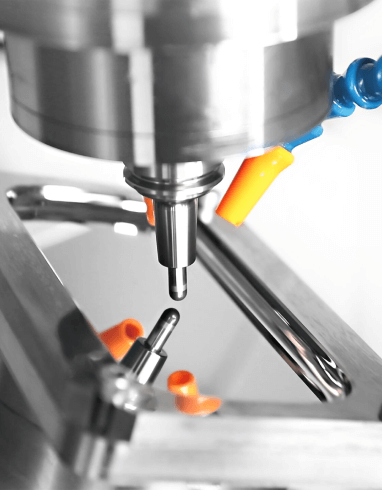

Accessories and peripherals

Mist collector

Cooling system

Coolant filtration equipment and magnetic separator

Learn more about PERIFERIQ

Design and development of industrial automation tailored to your needs

Automatic doors

Automated loading and unloading systems

Safety and cleaning systems

Interfaces for external workholding systems

Learn more about OTOMATIQA