Casos de éxito | 25.09.2025

PROMEBA: Technology That redefines productivity

By: Hebert Garza

25.09.2025

Share

PROMEBA, a specialist in the manufacture of machined parts for the automotive industry and located in the state of Guanajuato, opened its doors to share its achievements, extensive production capacity, and the implementation of new technologies.

“Our relationship with HEMAQ began in 2020, when we needed to develop a new business unit. We learned about them through our clients and other recommendations, so we approached them. Together, we carried out the necessary analysis to acquire our first OKUMA machine,” said PROMEBA’s Director of Operations.

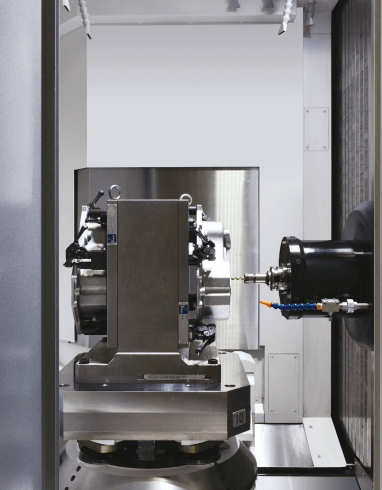

Over 30 OKUMA machines in operation

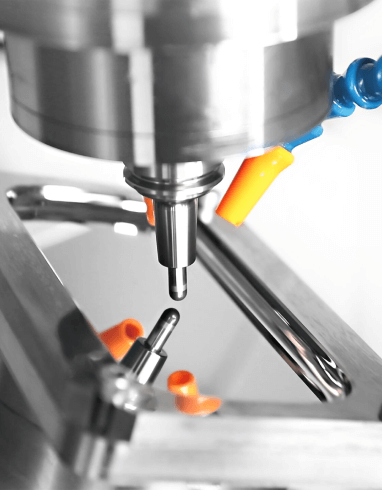

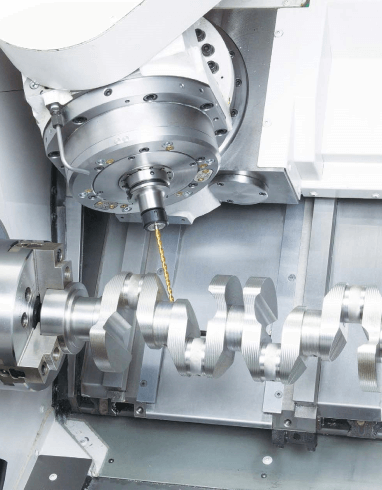

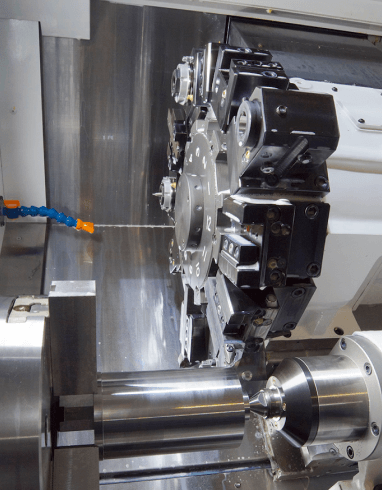

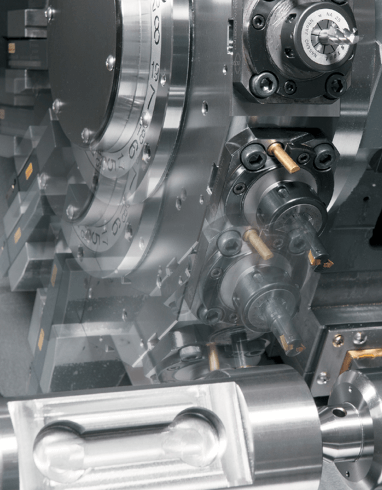

The first equipment acquired was a 2SP-2500H multi-spindle CNC lathe, a machine designed to produce complex parts. Since then, PROMEBA has added more than 30 OKUMA machines to its facility, including horizontal and multi-spindle lathes, which operate non-stop throughout the year thanks to the strong partnership with HEMAQ.

“The starting point of our relationship was the need to increase installed capacity. However, incorporating their CNC machines has also significantly improved productivity by providing precision and accuracy through their design and technology,” emphasized PROMEBA’s Manufacturing and Projects Manager.

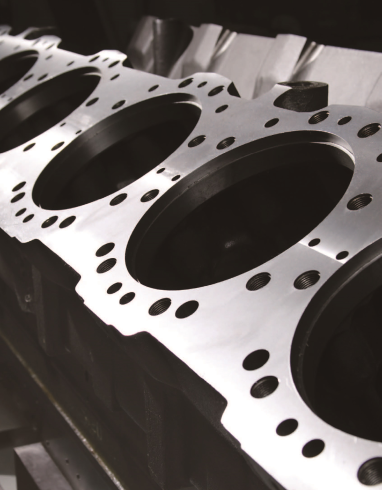

Comprehensive solutions for the automotive industry

“At PROMEBA, we specialize in manufacturing precision-machined parts for the automotive sector,” the team explained. “The key was that HEMAQ didn’t just offer machines, they offered a comprehensive solution that met production volume, tolerances, and part geometries, while also making us more competitive.”

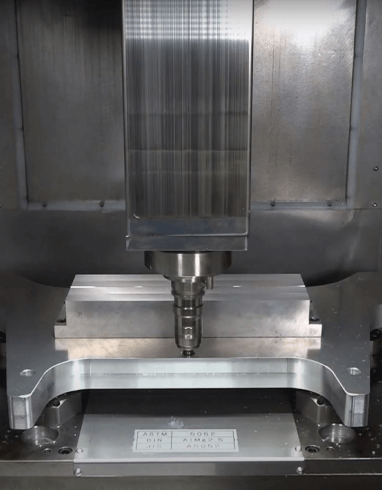

Both companies collaborated closely on engineering, process design, and the selection of tools and accessories to achieve efficient machining. This collaboration became the foundation of a long-term, trust-based partnership, one strengthened by HEMAQ’s philosophy of always-available service.

“Thanks to their attention and support, we have been able to increase productivity, as well as the stability and robustness of our processes. Overall, we’ve made a 180° turn in terms of production, reaching high levels of efficiency,” added PROMEBA’s Head of New Business Development.

Technology that boosts competitiveness

The 2SP-2500H model reduces delivery times while maintaining exceptional surface finishes. “Their guidance has been key in helping us strategically select the most suitable CNC machinery. This translates into quality products, with the required volumes and at competitive prices, directly supporting our QQS philosophy: Quality, Quantity, and Service.”

By continuously reviewing the technology and performance of their OKUMA machines, PROMEBA remains committed to modernization and expansion, pursuing steady and sustainable growth. “We’ve chosen to continue working with HEMAQ to upgrade our equipment. This has allowed us to increase efficiency and expand production capacity in a second business unit.”

Constant support and personalized service

PROMEBA emphasizes that personalized and consistent support is crucial for uninterrupted operations. “HEMAQ’s attention has been constant and personal; among the closest we have. That proximity allows them to truly understand our needs and provide solutions tailored to our operations.”

As a CNC machining supplier, PROMEBA is constantly developing new projects, driven by efficiency and production excellence. “HEMAQ has greatly supported us in several developments through their know-how, covering machines, accessories, and tooling. They’ve provided the framework that enables us to manufacture new products with tighter geometric tolerances and higher precision,” said the Operations Department.

Excellence through technology

PROMEBA’s capacity continues to grow, accompanied by new and challenging projects. “We’re currently machining a complex part due to the large amount of excess material to remove. However, thanks to OKUMA’s technology, we are extremely satisfied with the process and equipment selection. These machines are precise, efficient, and help us remain highly productive.”

Through the combination of strong service relationships, support for new business development, and state-of-the-art technology, PROMEBA maintains world-class quality standards. “We’ve achieved a high-performance rating, the machinery has been key to ensuring stable processes, minimal scrap rates, and three consecutive years with zero rejected parts,” the team concluded after a highly productive visit to their facilities