Industria | 27.05.2025

Aerospace industry: CNC machining challenges

By: Hebert Garza

27.05.2025

Share

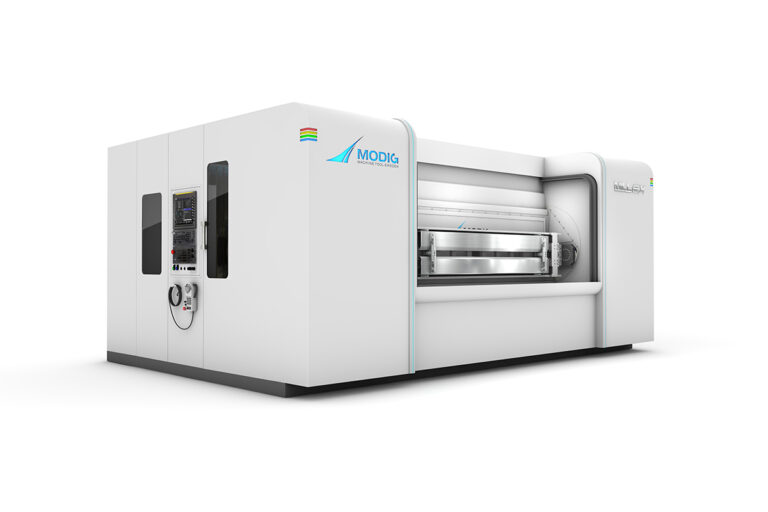

The aerospace industry demands extreme precision, advanced materials and full traceability. When it comes to machining large parts, these requirements become even more complex, presenting significant challenges for shops and manufacturers. However, those who rely on specialized machinery such as Modig’s are gaining a clear competitive advantage in this highly demanding market.

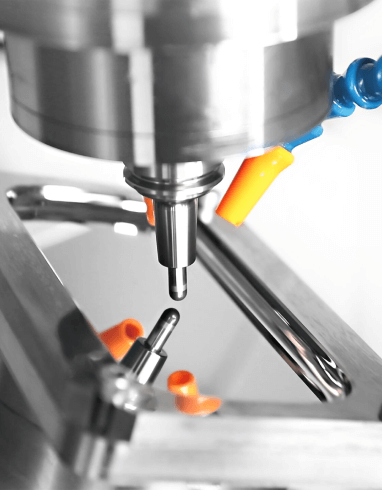

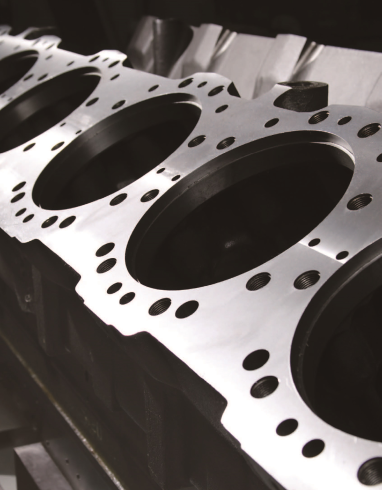

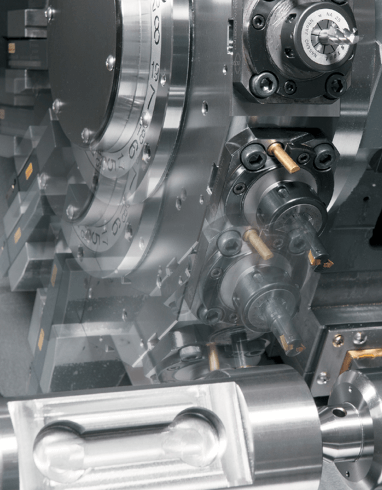

Tight tolerances on complex geometries

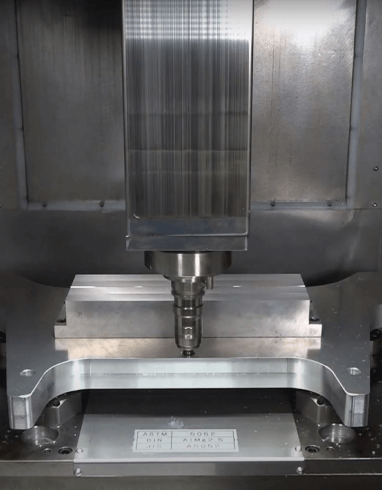

Large parts, such as stringers, structural beams or wing rails, must meet micron tolerances even on dimensions of several meters. Machines like Modig’s RigiMill MG Vertical Machining Center,

a 3-, 4- or 5-axis machine with large machining capabilities, are designed specifically for these scenarios. Thanks to its structural rigidity and gantry-type architecture, it offers repeatable accuracy over long paths, ideal for machining critical aircraft structural components.

Traceability and documentation

Modig’s machining centers can be integrated with real-time monitoring systems, production data collection and advanced sensing, meeting the quality and traceability standards required by aerospace OEMs such as Airbus, Boeing or Embraer.

Competitive advantages of investing in machinery for large parts

With equipment such as the RigiMill MT, manufacturers can offer machining services for wing spars, fuselage structures or structural components up to 20 meters, a capability highly valued by aerospace contractors, gaining access to new markets and higher value contracts.

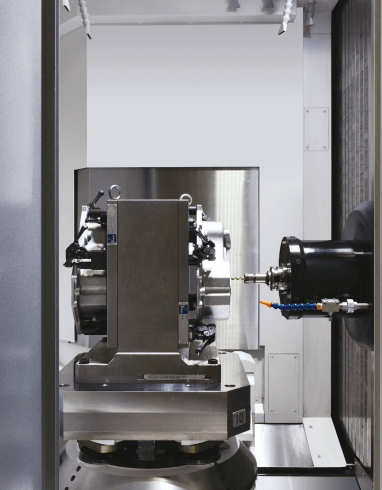

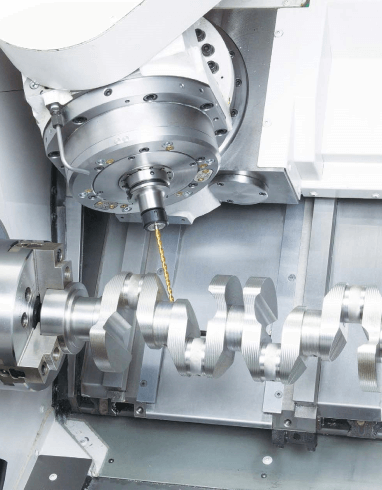

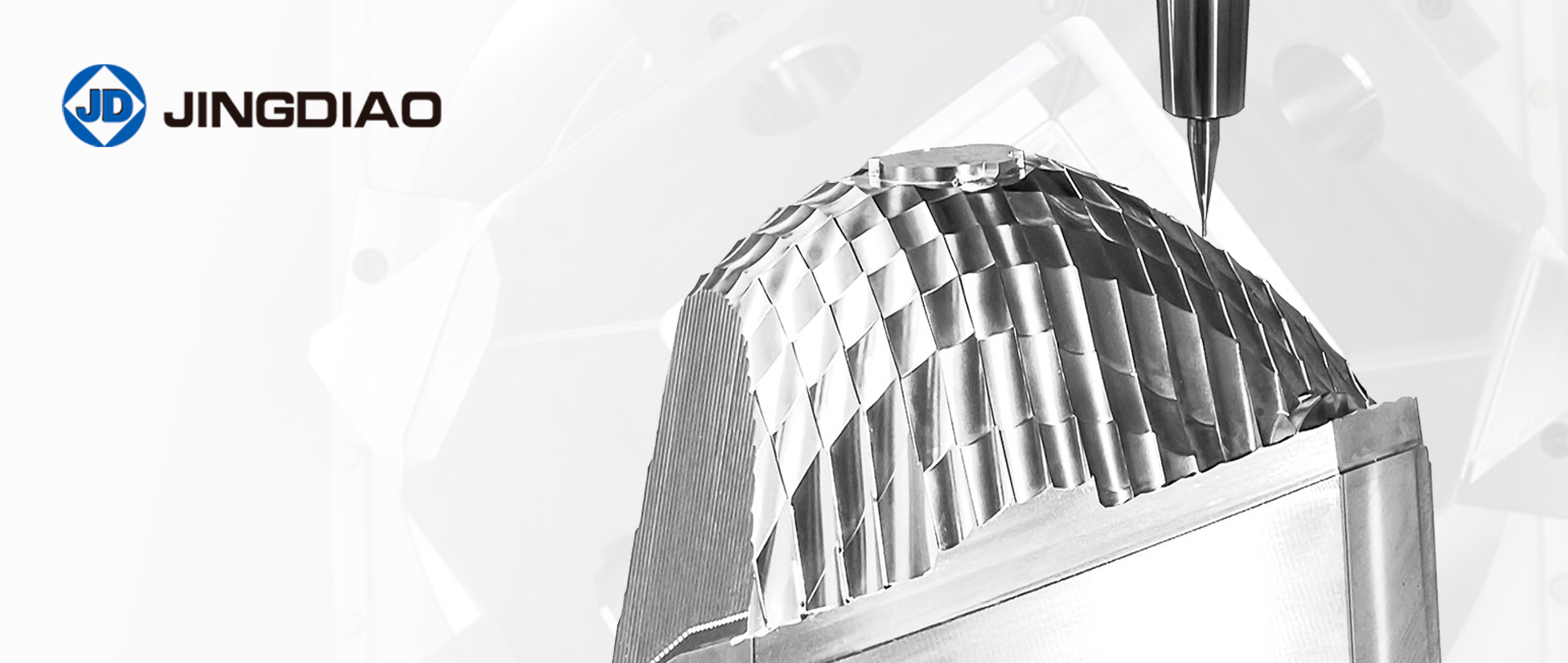

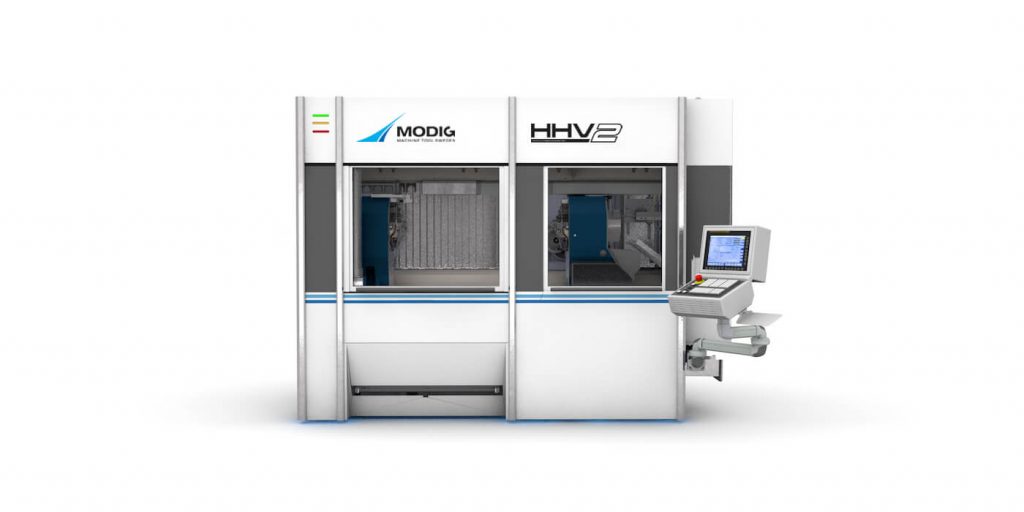

By internalizing critical processes with Modig technology, manufacturers gain autonomy, which translates into less outsourcing and greater quality control. The HHV2, for example, allows complete aluminum profiles to be machined in a single pass, eliminating intermediate processes and reducing the margin for human error.

Modig’s HHV2 machining center is one of the most widely used machines in the aerospace industry.

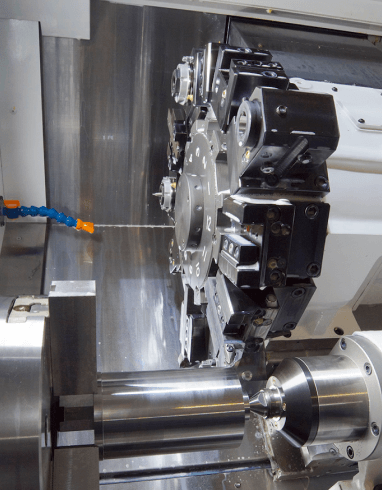

Modig also stands out for integrating automation, fast tool change, 5-axis heads and continuous material feed. This turns its centers into true compact production cells for medium and long series, increasing productivity levels thanks to its integrated technologies.

Companies with Modig technology are perceived as high-end suppliers, capable of meeting international quality standards. It is not for nothing that many suppliers specialized in aerospace materials and parts use their machines in AS9100-certified plants. And, although Modig is strongly focused on the aerospace sector, its solutions are perfectly applicable in industries such as defense, railway and power generation, allowing to diversify projects and maximize the return on investment.

Machining large parts in the aerospace industry is one of the most complex challenges in modern manufacturing. But it also represents one of the greatest opportunities for growth, innovation and differentiation. Investing in machinery like Modig’s, with specific solutions for advanced materials, high precision and automation, is investing in the future of industrial competitiveness. The market does not only reward technical capacity: it rewards strategic vision. Contact us and find out how we can help you achieve this vision.