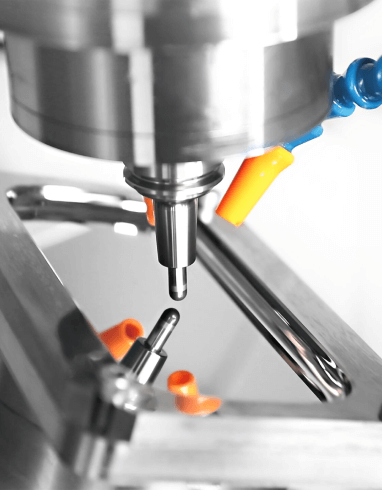

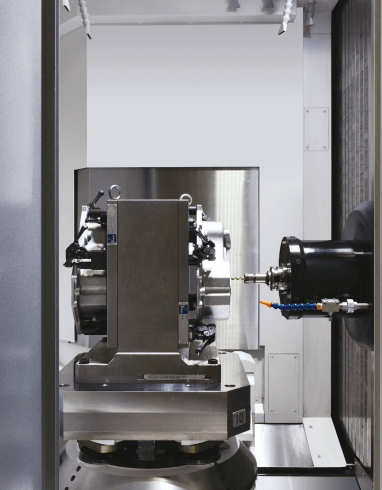

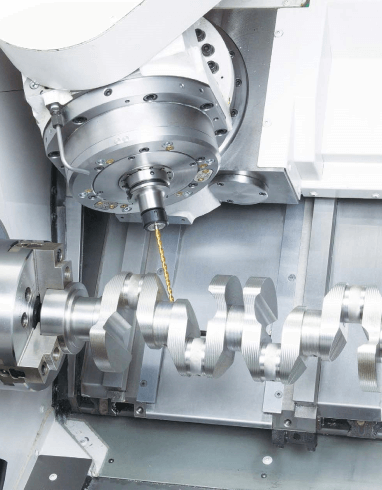

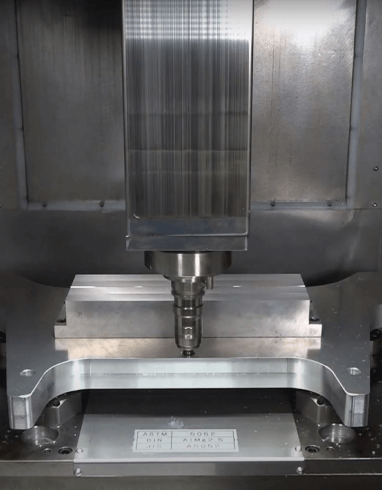

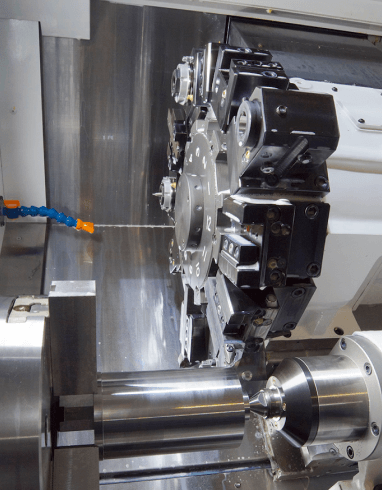

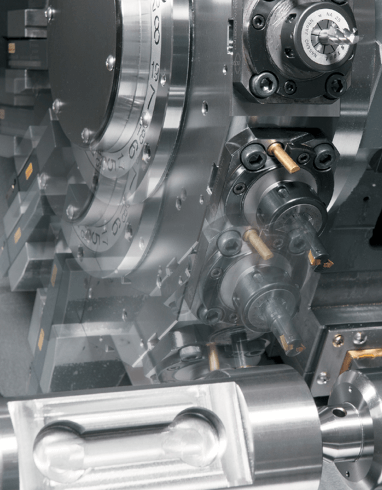

Jingdiao VTA600: Precision and Speed Within Reach In a landscape where precision and efficiency define competitiveness, the JingdiaoVTA600 High-Speed Machining Center stands out as a high-performance solution for shops aiming to move toward advanced manufacturing — without sacrificing space or budget. Compact, rigid, and highly accurate Featuring a bridge-type structure and a 24,000 RPM direct-drive spindle, the VTA600 provides exceptional rigidity for machining materials …

Jingdiao VTA600 High-Speed Precision Machining Center | HEMAQ Mexico