Industria | 12.02.2026

How to Buy a CNC Machine: What You Really Need to Consider?

By:

12.02.2026

Share

How to Buy a CNC Machine starts with understanding that purchasing a new CNC machine tool is one of the most critical decisions in any manufacturing operation. The typical starting point is a comparison chart—travels, work envelope, spindle speeds, weight, price—but while this exercise is useful, it does not always tell the full story.

Based on HEMAQ’s experience since 1988, we have learned that the most successful purchasing decisions go beyond technical specifications and focus on Total Cost of Ownership (TCO)—in other words, the machine’s true impact throughout its entire service life.

Below, we share the key factors that make the difference between a “correct” purchase and a truly profitable investment.

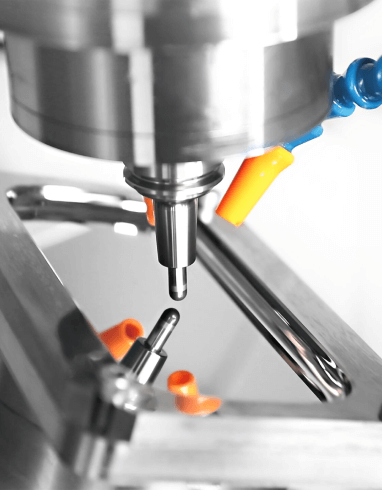

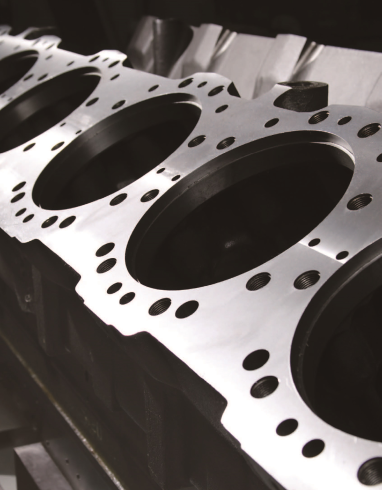

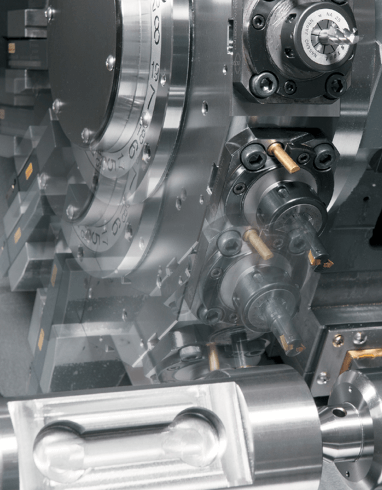

1. Productivity: The Real Driver of Return on Investment

In many traditional analyses, productivity is assumed—but not always properly measured. A well-built, rigid, high-quality machine can generate significant gains in daily output.

We are talking about:

- Shorter machining cycles

- Better tolerance control

- Improved surface finishes

- Elimination or reduction of rework

These factors directly impact the profitability of every single part produced—day after day—and often far outweigh the initial price difference between two machines.

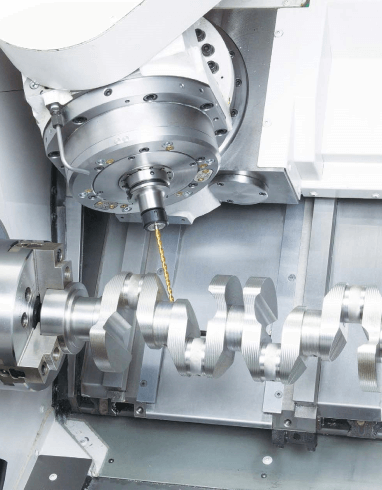

2. Tooling Costs: A Silent but Critical Expense

Machine rigidity is a factor that should never be underestimated. It is widely proven that a machine with poor rigidity dramatically increases cutting tool consumption.

In certain materials—such as titanium, Inconel, and other difficult-to-machine alloys—a poor decision can result in accumulated tooling costs reaching up to four times the machine’s original purchase price over its lifetime.

We have seen customers make very smart decisions by selecting machines that, while requiring a higher upfront investment, deliver substantial and sustained savings in tooling. This is undoubtedly an analysis worth conducting from the outset.

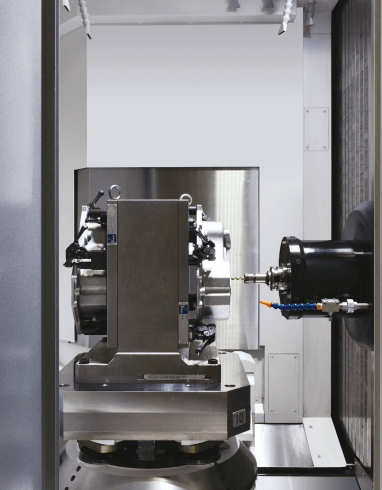

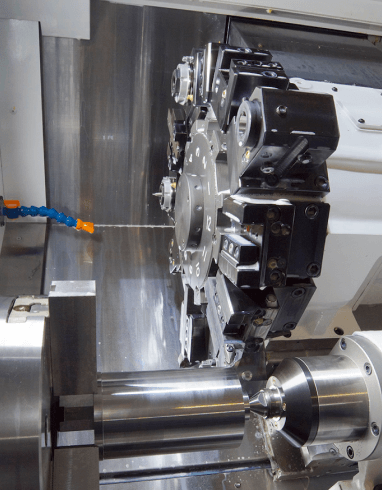

3. Maintenance Costs: When the “Familiar” Becomes More Expensive

Another key aspect is reviewing the real maintenance history of the equipment currently running in your plant: spare parts, unplanned downtime, and rising operating costs.

In several cases, when comparing these ongoing expenses to the cost of acquiring a new machine, customers have been surprised to find that investing in new equipment is actually more economical than continuing to maintain aging assets. When the full picture is analyzed, the purchase stops being an expense and becomes an operational cost-saving strategy.

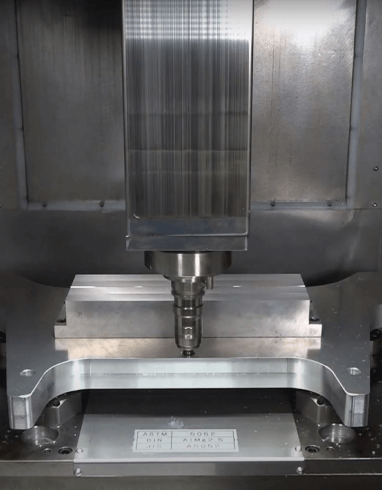

High-Impact Numbers That Don’t Appear in a Spec Sheet

Some of the most important variables never show up in a technical comparison chart, yet they play a decisive role in the success of the investment.

Key tools for a deeper evaluation include:

- Real-world time studies

- Physical cutting tests (beyond simulation)

- Site visits and conversations with users operating similar equipment

The importance of knowing how to buy a CNC machine

This type of data provides a far clearer and more reliable foundation for making an informed decision.

At HEMAQ, we are always available to support our customers at every stage of the evaluation and purchasing process. Our goal is to help you invest with confidence, long-term vision, and measurable results.

We hope these insights help you analyze your next investment with greater clarity and certainty.

Visit hemaq.com for more information.