We address your frequently asked questions

Here you will find answers to the most common inquiries about our equipment and services. If you have any questions that are not covered here, please feel free to contact us; we are here to assist you.

Equipment

What should we consider when choosing a suitable CNC Machine Tool?

We must start from the application, i.e. the product to be machined. The basic considerations are: part material, dimensions, processes, finishes and production volume. Our sales consultants are trained to advise you on stand alone projects, complete processes and turnkey projects.

What kind of capabilities should be considered when choosing a CNC Machine?

It is necessary to consider the capabilities of the equipment that the project requires, such as working space, strokes, power, load capacity, table size, sizes and types of tools to be used, as well as dimensions and weights of the devices and parts, among other technical aspects that our engineers will support you with during the consulting process.

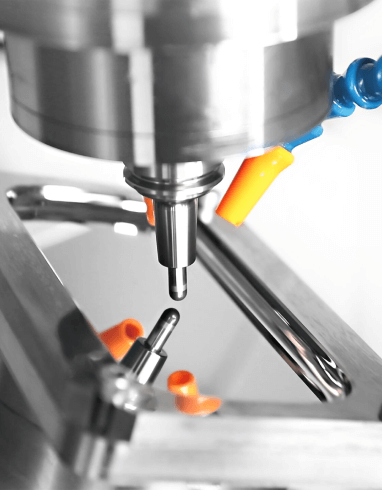

How is a spindle selected?

The spindle is the heart of a CNC machine tool. Depending on the type of material we are going to machine, we must choose the right speed, power and torque range for our project. Whether by torque or revolutions per minute (rpm), spindles operate very differently, so the one with more rpm, power or torque is not necessarily better. Most of the time you can configure a machine with different spindles, but you will certainly need to have other considerations around the equipment to complement its machining capabilities.

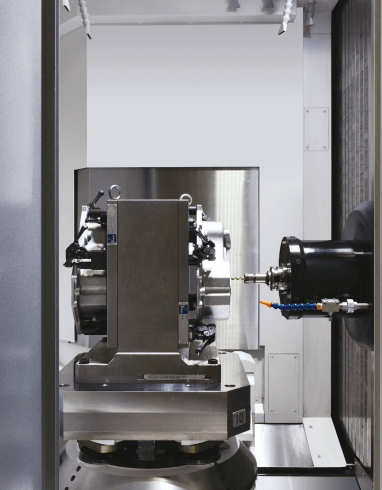

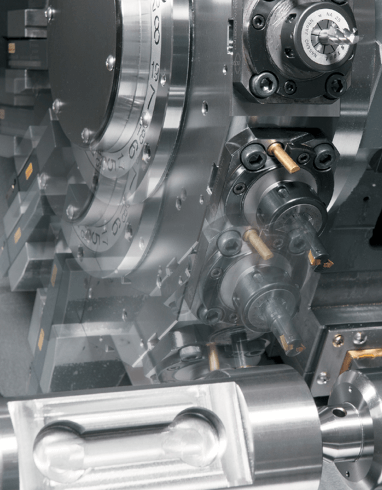

What are the advantages of a multifunctional lathe?

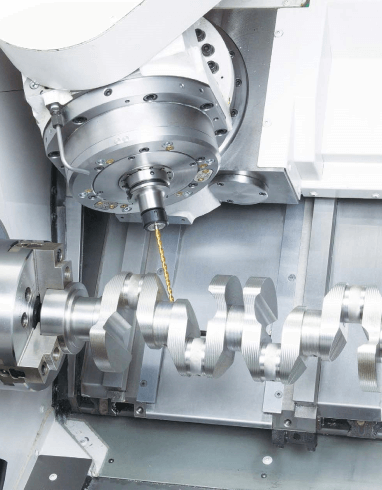

These machines stand out for their high flexibility and productivity thanks to their shorter cycle times, better final part quality, lower labor requirements and much shorter delivery times. This is due to the fact that it achieves simultaneous 5-axis and 6-sided machining in a single operation; it also has greater tolerance control, shorter waiting times between operations and lower amortization costs.

What types of CNC machines does HEMAQ offer?

At HEMAQ we offer a wide range of CNC machine tools such as Lathes, Machining Centers, Milling Machines, Multitasking Machines, and Double Column Machines, designed for different machining and manufacturing applications.

What CNC machine brands does HEMAQ distribute?

HEMAQ is the official distributor of OKUMA, as well as other world-leading CNC technology brands such as MODIG, HORKOS, JINGDIAO, and KIRA, ensuring quality, precision, and specialized support.

What is Computer Numerical Control (CNC)?

Computer Numerical Control (CNC) is an automated system that uses software and programming to control machine tools with high precision.

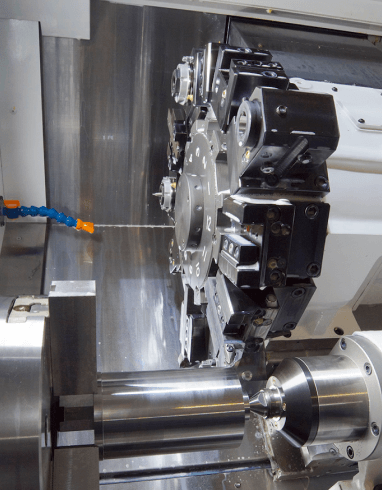

What are the advantages of a CNC lathe?

A CNC lathe offers higher precision, reduced human errors, optimized production times, and versatility in part machining.

Does HEMAQ offer financing for CNC machines?

Yes, HEMAQ provides flexible direct financing plans to make it easier to acquire CNC machine tools tailored to each company’s needs.

What are the advantages and disadvantages of a CNC machine?

CNC machines stand out for their precision, repeatability, and efficiency. Among the disadvantages are the higher initial investment and the need for specialized training.

How much does a CNC machine cost?

The price of a CNC machine depends on the type, brand, size, and technical specifications. At HEMAQ we offer personalized consulting to help you find the best option according to your budget and needs.

Investment

Which is the most cost-effective equipment?

It is vital to identify all those factors that affect or benefit the project, and to consider that the useful life of CNC equipment of this type is at least 15 to 20 years. Although there is equipment with more than 30 years operating normally.

How is the total cost of ownership of CNC equipment calculated?

The Total Cost of Ownership (TCO) of a CNC equipment is an auxiliary financial estimate of the direct and indirect costs of a piece of equipment, so that it is easier to choose it accurately and objectively. To do so, we must take into account the needs and scope of the project, as well as the hidden variables that affect or benefit the project; but also estimate the costs and benefits that a CNC equipment will bring throughout its productive life, so that our analysis will serve as a competitive advantage.

How long does it take to amortize the price of a CNC Machine Tool?

Amortizing the price of an equipment in 1 or 2 years would not be very competitive, however, thanks to the depreciation of more than 10 years of our equipment, the amortization is possible in a period of 3 to 5 years, thus investing in a high-end equipment with a price 10 to 15% higher, because with its useful life of more than 15 years is much more profitable.

Why choose a more expensive equipment?

We often think in terms of what we need immediately, and not how a smart investment can increase our profitability and transform our productivity. For example, a Horizontal Machining Center requires a larger investment than its Vertical counterpart, however, the former integrates elements of greater size, quality and performance that make it optimal for precise and continuous machining, ideal for expanding your capacity. In addition, it has capabilities such as higher spindle utilization, heat dissipation and tool life, indicators that consolidate greater flexibility and integral profitability.

What is the process to apply for a financing?

In HEMAQ we have direct financing without third party intervention from 12 months with a preferential fixed rate. Contact our sales executives and learn about the different options we have to help you.

Common Questions

How much does a CNC machine cost in Mexico?

The cost of a CNC machine in Mexico depends on the type of equipment, its capacity, the level of technology, the brand, and the industrial application. In general terms, a CNC machine can be found starting at approximately $300,000 MXN in basic configurations, while high-performance industrial equipment can exceed $5,000,000 MXN. At HEMAQ, we analyze each project to recommend the most suitable solution based on the production needs and budget of each company.

What are the most commonly used CNC machines?

The CNC machines most widely used in the manufacturing industry are:

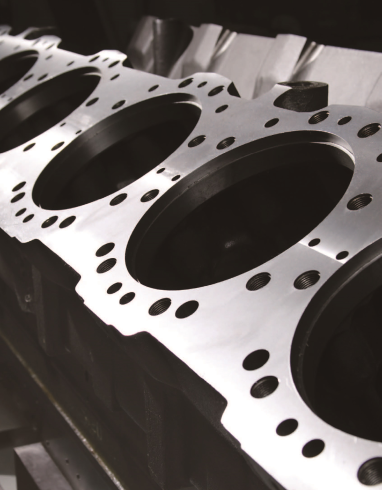

· CNC lathes, used for the production of cylindrical parts with high precision.

· CNC milling machines, ideal for versatile machining operations.

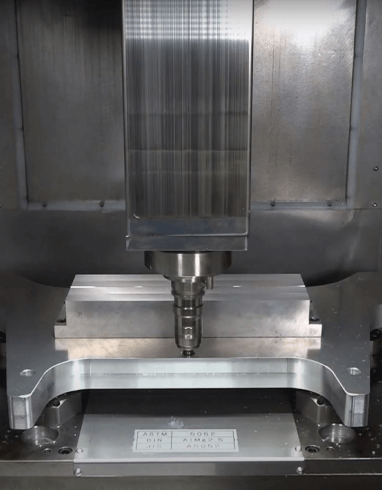

· CNC machining centers, both vertical and horizontal, widely used in industrial production.

· CNC cutting machines (laser, plasma, or router), applied to metal, wood, and other materials.

These machines are essential in sectors such as metalworking, automotive, aerospace, and manufacturing in general.

How much does a 5-axis CNC machine cost?

The price of a 5-axis CNC machine in Mexico typically starts at around $2,500,000 MXN and can exceed $10,000,000 MXN, depending on the brand, CNC control, required precision, and type of applications. This type of machinery allows complex parts to be manufactured in a single setup, optimizing time, quality, and production processes.

What are the advantages of a CNC machine?

CNC machines offer significant benefits to the industry, including:

· High precision and repeatability in part manufacturing.

· Greater efficiency and productivity in manufacturing processes.

· Reduction of human error and material waste.

· Ability to consistently produce complex geometries.

· Optimization of operating times and costs in the medium and long term.

For these reasons, CNC technology is key to industrial competitiveness.

What are the functions of a CNC operator?

The main responsibilities of a CNC operator include:

· Preparing and operating the CNC machine according to technical drawings and specifications.

· Loading, adjusting, and running CNC programs.

· Monitoring the machining process and proper equipment operation.

· Verifying the dimensional quality of the produced parts.

· Performing basic maintenance and reporting incidents.

Their work is essential to ensure efficiency, quality, and safety in the production process.

What is CNC and what does it mean?

CNC stands for Computer Numerical Control. It is a system that allows machine tools to be controlled through computer programs, achieving more precise, repeatable, and efficient machining processes. CNC is a fundamental technology in modern industry and advanced manufacturing processes in Mexico.